Автоматический дисковый центробежный сепаратор для молочного крема с

- Категория: Separation Equipment >>>

- Поставщик: Yixing,Huading,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 29750.48 $* | 31238.9 $* |

| Aug-15-2025 | 29500.50 $* | 30975.24 $* |

| Jul-15-2025 | 24750.26 $* | 25988.84 $* |

| Jun-15-2025 | 29000.59 $* | 30450.94 $* |

| May-15-2025 | 25250.53 $* | 26513.25 $* |

| Apr-15-2025 | 28500.22 $* | 29925.28 $* |

| Mar-15-2025 | 28250.75 $* | 29663.90 $* |

| Feb-15-2025 | 28000.11 $* | 29400.55 $* |

| Jan-15-2025 | 27750.43 $* | 29138.58 $* |

Характеристики

Factory direct automatic disc centrifugal milk cream separator With Trade Assurance

Product Detail

| Bowl material | EN 1.4418, 1.4462, 1.4410 |

| PLC | SIEMENS |

| HMI | SIEMENS |

| Frequency inverter | ABB / SIEMENS |

| Bearing | SKF |

| Product Keywords | automatic disc centrifugal milk cream separator |

Related criterion:

- Quality guarantee system of ISO9001-2000

- JB/T502-2004 standards

- One year warranty

- Life - long service

- 2006/42/EC (Machinery)

- 2014/35/EU (Low Voltage)

- 2014/30/EU (Electromagnetic Compatibility)

SKSD and MCSX series centrifugal Cream Separator are special disigned for separation, clarification, and standardization of milk . Separation of whey.

Separation of milk or whey into skim milk and cream. The self-cleaning bowl makes the machine suitable for fully automatic

cleaning-in-place (CIP). Both light phase and heavy phase are discharged under pressure. Sediment is ejected from the bowl at pre-determined intervals while the bowl is rotating at full speed.

Skimming efficiency of cream separator is expressed as residual fat content in the skimmed milk. At rated capacity, Huading Separator generally give a residual fat content lower than 0.05%.

- Self-cleaning disk type bowl

- Frame made of cast iron

- Machine driven by a 3-phase AC motor

- Automatic lubrication system

- Centripetal pump for liquid discharge

- All parts coming into contact with the products made of stainless steel

the disc stack separator separates solids and one or two liquid phases from each other in one single continuous process, using extremely high centrifugal forces. When the denser solids are subjected to such forces, they are forced outwards against the rotating bowl wall, while the less dense liquid phases form concentric inner layers. The area where these two different liquid phases meet is called the interface position. This can be easily varied in order to ensure that the separation takes place with maximum efficiency. Inserting special plates (the "disc stack") provides additional surface settling area, which contributes to speeding up the separation process dramatically. It is the particular configuration, shape and design of these plates that make it possible for a disc stack centrifuge to undertake the continuous separation of a wide range of different solids from either one or two liquids. The concentrated solids phase formed by the particles can be removed continuously, intermittently or manually, depending on centrifuge type and the amount of solids involved in the specific application.

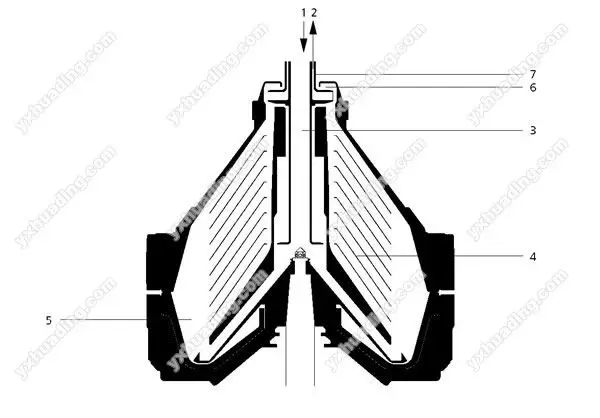

2-phase separation disc stack centrifuge separator

1 Feed

2 Discharge

3 Inlet tube

4 Disc stack

5 Solids holding space

6 Centripetal pump chamber

7 Centripetal pump

Separation takes place inside a rotating bowl. The feed is introduced to the rotating centrifuge bowl from the top via a stationary inlet pipe , and is accelerated in the distributor, before entering the disc stack. The distributor is designed especially to ensure smooth acceleration of the feed liquid. The separation of liquid-solids takes place between the discs, with the liquid phase moving through the disc stack to the centre and is led to the paring chamber, where it is pumped out of the bowl by means of a built-in paring disc. The solids is collected in the periphery, from where it is discharged intermittently into the solids collecting cover. The solids discharge is achieved by a hydraulic system which at pre-set suitable intervals forces the sliding piston to drop down and thus opening the solids ports at the bowl periphery.

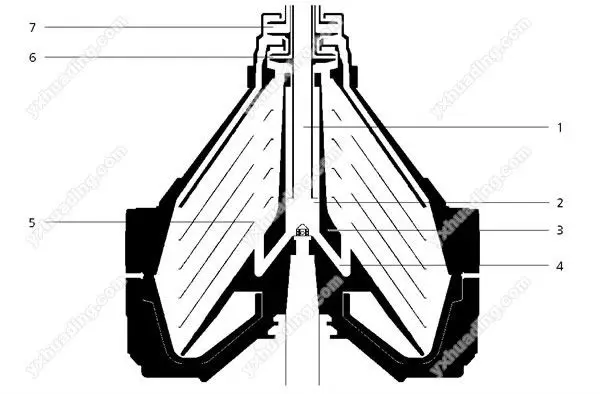

3-phase separation disc stack centrifuge separator

1 Inlet tube

2 Central bore

3 Distributor

4 Distributor bore

5 Rising channels

6 light phase centripetal pump

7 heavy phase centripetal pump

The suspension to be separated is fed into the separator bowl from the top through a feeding pipe and enters the disc stack. The heavy phase and heavy sludge are forced towards the periphery of the bowl, while the light phase flows towards the centre of the bowl, from where it is pumped out for further processing. The heavy phase is led over a top disc into a chamber where a paring device pumps it out of the separator. Solids collects in the sludge space and is discharged intermittently and automatically. The discharge is achieved by a hydraulic system, which at preset suitable intervals forces the sliding piston to drop down, thus opening the solids ports at the bowl periphery. The solids is collected in the frame, and leaves the centrifuge via a cyclone.

Usually, self-cleaning disc stack centrifuge separator is divided into two types. One is used for solids and two liquid phases from each other in one single continuous process, it is so called purifier. The other is used for solids and one liquid phase from each other, it is so called clarifier.