Экологичная Изолированная eps бетонная цементная сэндвич-машина из полистирола для легкой стеновой

- Категория: Other Construction Material Making Machinery >>>

- Поставщик: Yantai,Demeng,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.63 $* | 0.11 $* |

| Aug-15-2025 | 0.94 $* | 0.10 $* |

| Jul-15-2025 | 0.63 $* | 0.85 $* |

| Jun-15-2025 | 0.30 $* | 0.5 $* |

| May-15-2025 | 0.43 $* | 0.44 $* |

| Apr-15-2025 | 0.56 $* | 0.32 $* |

| Mar-15-2025 | 0.52 $* | 0.80 $* |

| Feb-15-2025 | 0.93 $* | 0.51 $* |

| Jan-15-2025 | 0.90 $* | 0.46 $* |

Характеристики

3D decorate concrete eps wall panel making machine / lightweight eps cement concrete wall panels making machine / EPS cement wall panel machine

Precast concrete fully automatic Light weight EPS cement sandwich panel machine

EPS cement wall panel machinery have SIX parts:

1) Foaming system

2) Cement & sand storage and convery

3) Mixer system

4) Measuring and dust collector system

5) Mould system

6) Other accessories & tools

Sandw

1.1) Foaming system

- Application: Expand EPS foam particle

- Advantages of foaming system:

1. Full Automatic

2. High speed EPS output

3. Easy operation

4. Long-term stability

1.2) Cement & sand storage and convey

1.2.1 cement storage:

volume: 40T

1.2.2 screw conveyor

Screw blade diameter: 200mm

Length of screw: 200mm

Rotating speed:90r/min

Conveying capacity:11m3/h

Power: Pd1=10m(KW) 2.2

Pd1=30m(KW)3.2

Sandwich wall board production line

1.3) Mixer system

- Application: Mix raw material

1. Full Automatic.

2. High output.

3. Easy operation.

1.4) Measuring and dust collector system

1.4.1 Cement, sand, water measuring system

1.4.2 Dust collector

Collecting area: 24m2

Output pressure: 0.5-0.7mpa

Bearing pressure:5000pa

Quantity of pulse valve:4

Motor power: 1.5KW

Weight: 1350kg

1.5) Mould system

- Application: Form EPS cement sandwich panel

- Advantages of molding system:

1. Face panel and core forming by one time compound.

2. Low input, high output and returns.

3. Easy and convenient for operation.

4. Long life span.

Parameters for light weight panel equipment:

Product | Specification(mm) | Output/moulding car | |||

FPB | thickness | Length | Width | Pcs/car | square meters/car |

50 | 2270(2240/3000 | 610 | 54 | 74.8 | |

60 | 2270(2240/3000) | 610 | 48 | 66.5 | |

75 | 2270(2240/3000) | 610 | 42 | 58.2 | |

90 | 2270(2240/3000) | 610 | 36 | 49.8 | |

120 | 2270(2240/3000) | 610 | 30 | 41.5 | |

150 | 2270(2240/3000) | 610 | 24 | 33.3 | |

180 | 2270(2240/3000) | 610 | 20 | 27.8 | |

200 | 2270(2240/3000 | 610 | 18 | 24.9 | |

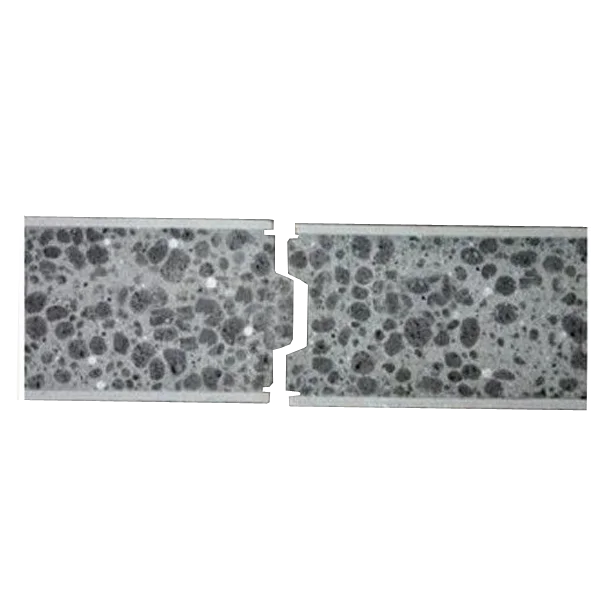

There are three kinds of wall panel

Vertical Mold Car :

Vertical mold car: It can produce sandwich wall panels and solid wall panels. Its advantage is bigger productions capacity. Like wall panel with 100mm thickness, it can produce 36 sheets per mold car.

Horizontal mol cars: It is multi-functional. It can produce all kinds wall panel. Compared with vertical kind, it can only produce 10 sheets per mold car. For example, if you want to produce 300 sheets per day/100 mm thickness: For vertical mold car, you only need to buy 9 sets mold cars For horizontal mold car, you need to buy 30 sets mold cars. So in this horizontal mold car, your investment in machine is higher than vertical mold car.

Horizontal Mold Car:

Applied range of light weight EPS wall panel

For interior and exterior wall partition on steel or concrete structure building, new construction or renovations. It can be widely applied to wall materials of various high and low buildings such as bank, office building, hospital, school, hotel, shopping mall, amusement, old house reconstruction, residence and workshop.

Lightweight Wall Panel Making Machine for Concrete Precast Houses:

1) Different specification for wall panel you can choose to produce.

2)The vertical design for moulding equipment saves much sapce for factory

3) Higher output and less waste.

4) Running in a high automatization and intellectualization, no pollution

Sandwich wall board production line

Q: How long is the warranty of your equipment?

A: 1year

Q: Do you supply spare parts?

A: Excellent easy broken parts support for buyers. Easy broken parts guarantee for one year.

Q: Will you provide training?

A: The training is free of charge , and our engineer will be on duty to train your worker.

Q: How will you provide installation&commissioning

A: Will provide 2~8 persons(adjustable according to the degree of automatic )for installation. Engineers team will go with your project.