Двухконечная машина для напольного покрытия из массива дерева

- Категория: Other Woodworking Machinery >>>

- Поставщик: Shandong,STX,Machinery,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 49385.53 $* | 51854.3 $* |

| Aug-17-2025 | 48970.29 $* | 51419.20 $* |

| Jul-17-2025 | 41085.96 $* | 43139.54 $* |

| Jun-17-2025 | 48140.53 $* | 50547.89 $* |

| May-17-2025 | 41915.59 $* | 44011.57 $* |

| Apr-17-2025 | 47310.16 $* | 49676.98 $* |

| Mar-17-2025 | 46895.72 $* | 49240.10 $* |

| Feb-17-2025 | 46480.33 $* | 48804.74 $* |

| Jan-17-2025 | 46065.23 $* | 48368.58 $* |

Характеристики

CE Solid Wood Parquetry Flooring Double End Tenoner Machine

- Professional Solution

- Applicable to Panel furniture, hutch ark door,etc; Frequency control of motor speed, high precision conveyor chain rolling guide feed system; Active on pressure strip, with electric lift; Double linear guide, ball screw motor adjustable wide.

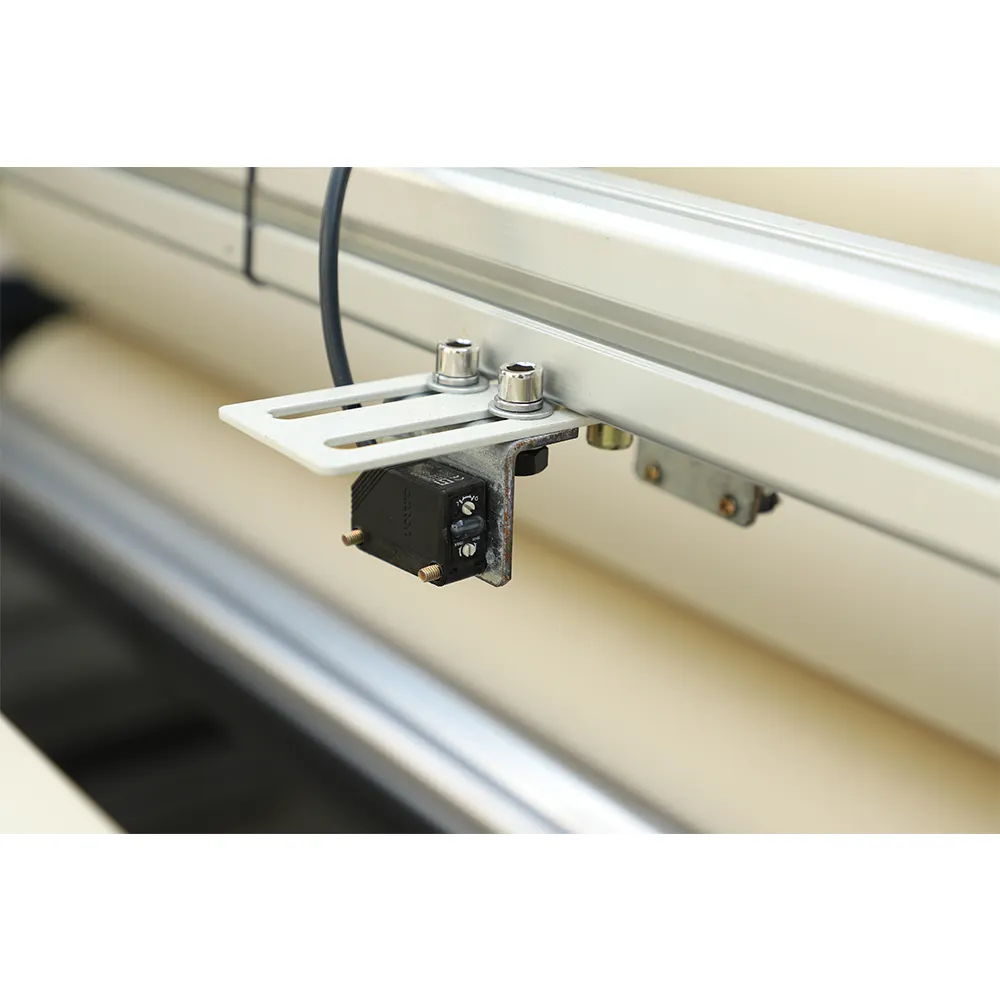

The floor plates are sent into the runnig bearings of the machining track with the material feeder and delivery rubber rollers, and the guide rails are made with extra hard materials, ensuring the machining precision.

With the imported PLC and the frequency conversion device, the double-end miller works very smooth.

Forcefully feeding decelerator features speed regulation by frequency inverter.

With the built-in cleaning brush wheel, the dust inside the track guide rail can be cleaned automatocally.

With the compact sawing shaft mechanism, the cutters are closed to the pressing belt, ensuring the machining stability.

Structure acting as ball-screw makes machine have more accurate adjustment.

Techinical Parameter

| Specification and Model | MX21024B |

| Feeding speed | 6-30m/min |

| Min. Working width | 300mm |

| Max. Working width | 2400mm |

| Min. Working thickness | 10mm |

| Max. Working thickness | 25mm |

| Spindle speed | 6000 |

| Vertical spindle rotation | 9000 |

| Sawing shaft diameter | Φ25.4mm |

| Maximum cutter diameter | Φ200mm |

| Main spindle dimension | Φ40mm |

| Extraction outlet size | Φ120mm |

| Max. mini saw blade diameter | Φ230mm |

| The length from feeding end of top pressing beam to dog | 400mm |

| Vertical spindle motor power | 3kwx4sets |

| Card buckle spindle motor power | 2.2kwx2sets |

| Feeding motor power | 3kw |

| Width adjusting motor power | 0.75kw |

| Scoring saw motor power | 3kwx2sets |

| Power take-off and landing | 0.25kw |

| Main saw motor power | 3kwx2sets |

| Total power | 32.65kw |

| Air pressure | 0.6MPa |

| The main electrial components are import and famous |

| The floor plates are sent into the running bearings of the manchining track with material feeder and delivery rubber rollers, and the guide rails are made with extra hard materials ensuring the machining precision |  |

| Ajusting width by high precision ball screw |

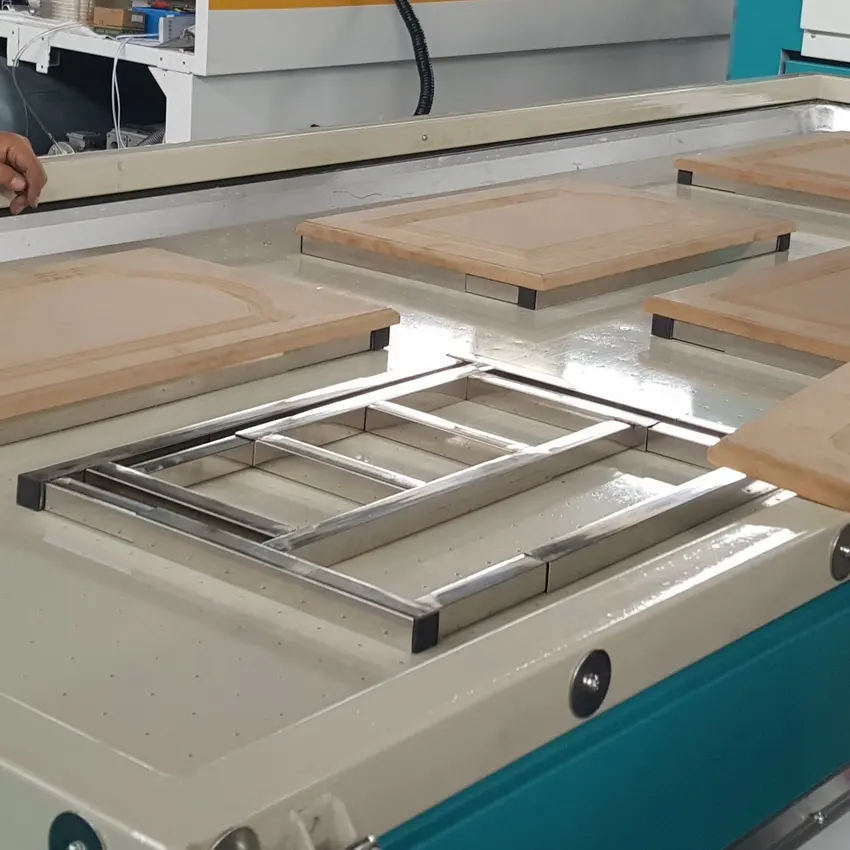

Beautiful Factory Veiw

Standardized Production Process