Автоматические выдувные машины для ПЭТ/выдувное формовочное оборудование изготовления пластиковых

- Категория: Выдувная машина >>>

- Поставщик: Zhangjiagang,Grandee,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.81 $* | 0.76 $* |

| Aug-16-2025 | 0.44 $* | 0.32 $* |

| Jul-16-2025 | 0.12 $* | 0.82 $* |

| Jun-16-2025 | 0.85 $* | 0.65 $* |

| May-16-2025 | 0.70 $* | 0.30 $* |

| Apr-16-2025 | 0.25 $* | 0.53 $* |

| Mar-16-2025 | 0.71 $* | 0.40 $* |

| Feb-16-2025 | 0.46 $* | 0.51 $* |

| Jan-16-2025 | 0.26 $* | 0.46 $* |

Характеристики

Auto Pet Blowing Machines / Blow Molding Equipment To Make Plastic Bottles

Specifications:

GD-A2 automatic water bottle blowing machine

CE approval

Speed: 2500pcs/h for 500ml pet bottle

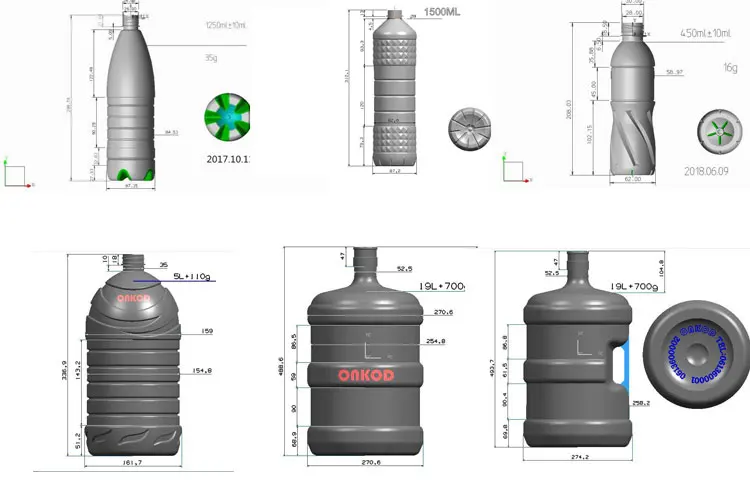

Volume:100ml-2000mL

Brief introduction of water bottle blow molding machine:

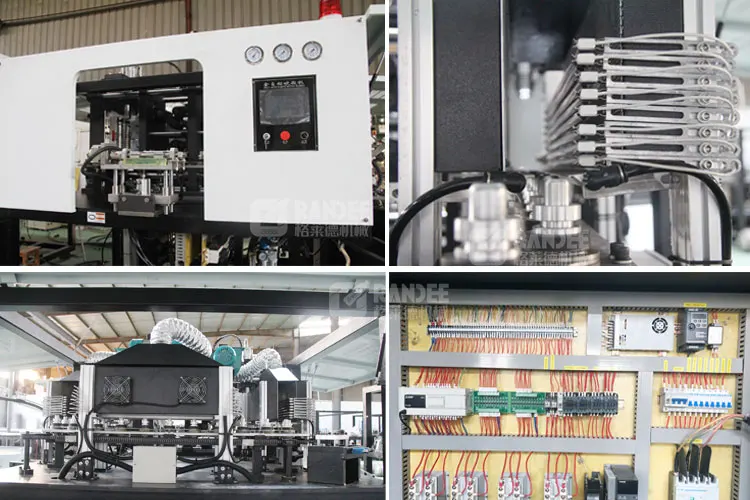

1.GD-A2 is the fastest liner blow molding machine in mainland of China by now. Its baking tunnel is separated from the blow station so that time for mold opening is shortened with a result of speedy blowing and high output, damage to machine is lessened so as to keep reliable performance and prolong service life, as well as machine runs more smoothly and steadily.

2.GD-A2 automatic stretch blow molding machine is equipped with patented preform loading system, which consists of two manipulators: rectilineal manipulator and overturning manipulator. The rectilineal manipulator moves preform with neck up to the preform holder, after heating, the overturning manipulator grips heated preform and overturn 180 put preform to blow station with neck down. After stretching and blowing, the bottle is taken off by overturning manipulator. The specially designed preform loading & bottle discharging system avoid possible damage to preform & bottle during transportation.

3.GD-A2 is controlled by PLC. The whole process from preform feeding to bottle discharging is completed automatically with advantages of labor saving and no pollution.

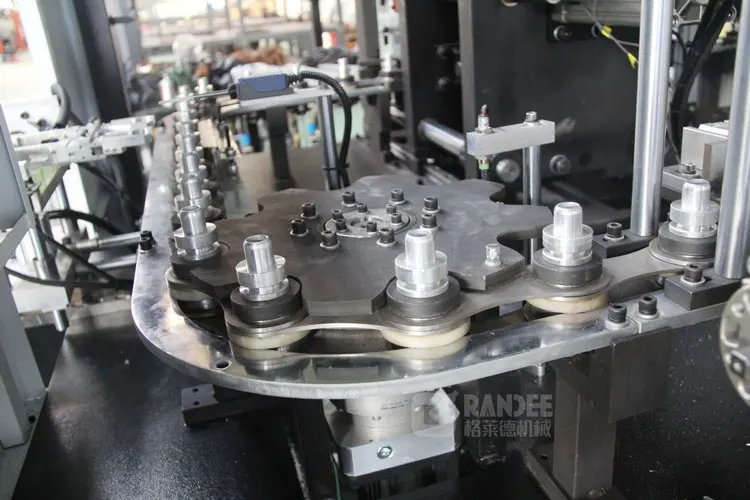

4.GD-A2 consists of three main parts: preform loading system, Heater channel & blow station.

Factory Supply Auto Pet Blowing Machines / Blow Molding Equipment To Make Plastic Bottles

Details show

Main techinical parameter:

Model | GD-A2 | GD-A4 | GD-A6 | GD-A8 | GD-A9 |

Capacity | 1800-2700 | 3200-4000 | 4000-5500 | 7000-8000 | 11000-12000 |

Bottle volume | 0.1-2.0L | 0.1-2.0L | 0.1-2.0L | 0.1-2.25L | 0.1-2.0L |

Cavity | 2 | 4 | 6 | 8 | 9 |

Usage power | 6.5kw | 13kw | 25kw | 45kw | 65kw |

Machine size | 1900*1280 *1930mm | 1900*1860 *1930mm | 4100*2400 *1930mm | 5160*4000 *3300 | 6160*4000 *3300 |

Weight | 2000kg | 3600kg | 4200kg | 7000kg | 9000kg |

Component list:

No | Name | Model | Brand | Country of origin |

1 | High pressure valve | 321H-35-2995 | Paker | America |

2 | Low pressure valve | 7321BAN00-DC24V | Paker | America |

3 | Check valve | 9C800S | Paker | America |

4 | Action solenoid valve |

| AirTAC | Taiwan |

5 | Host power | NES-200-24V | MEANWELL | Taiwan |

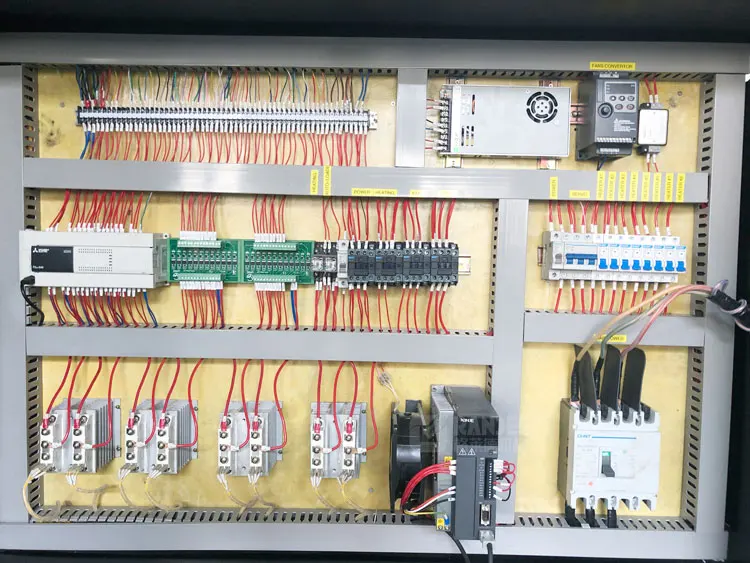

6 | PLC | FX1N-60MR | Mitsubish | Japan |

7 | Touch screen | TK6070IH | WEINVIEW | Taiwan |

8 | Standard cylinder | SC100X135-S | AirTAC | Taiwan |

9 | Thin cylinder | SDAS25X43-B | AirTAC | Taiwan |

10 | Pneumatic processing elements | GR20008-F1 | AirTAC | Taiwan |

11 | Swing cylinders | DSR-25-180-P | FESTO | Germany |

12 | Quick exhaust valve | SEU-3/8 | FESTO | Germany |

13 | Proximity sensor |

| Autonics | Korea |

14 | Photoelectric switch |

| OPTEX | Japan |

15 | Module |

| SEMIKRON | Germany |

16 | Ruby lamp | CR30-15DN | HAICHUANG | China |