Машина для бетонных стеновых панелей/машина

- Категория: Board Making Machinery >>>

- Поставщик: Dezhou,Haitian,Electromechanical,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 8330.39 $* | 8747.56 $* |

| Aug-16-2025 | 8260.95 $* | 8673.58 $* |

| Jul-16-2025 | 6930.45 $* | 7277.66 $* |

| Jun-16-2025 | 8120.78 $* | 8526.22 $* |

| May-16-2025 | 7070.12 $* | 7424.11 $* |

| Apr-16-2025 | 7980.33 $* | 8379.37 $* |

| Mar-16-2025 | 7910.74 $* | 8306.16 $* |

| Feb-16-2025 | 7840.42 $* | 8232.61 $* |

| Jan-16-2025 | 7770.25 $* | 8159.16 $* |

Характеристики

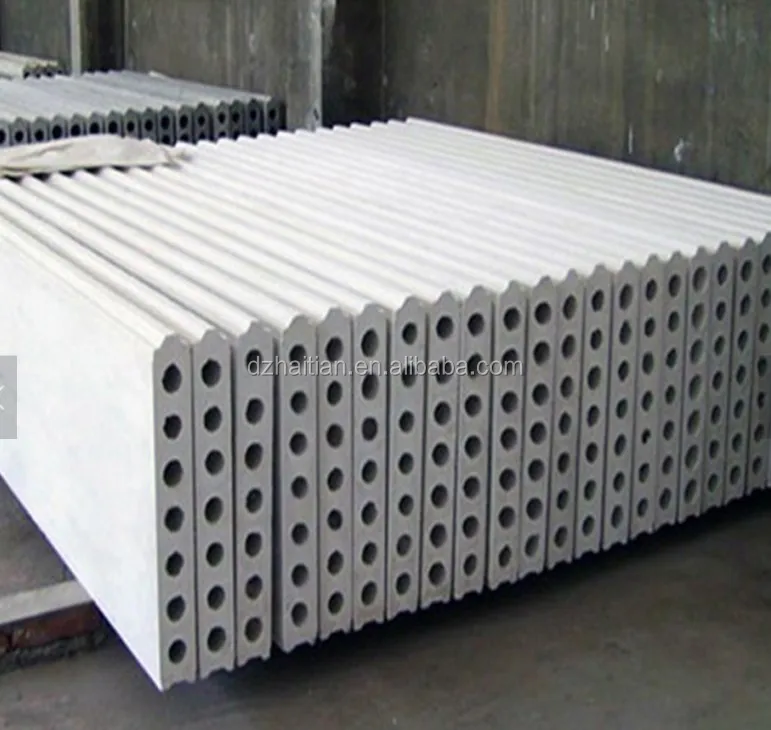

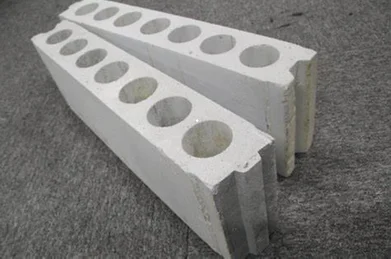

Concrete Lightweight Wall Panel Machine/ wall panel battery mould machine

Lightweight wall panel battery mould machine can produce lightweight hollow core wall panels, GRC wall panel, precast concrete exterior wall panels, precast concrete interior wall panels, fence panel, foam concrete wall panel, CLC wall panel, precast hollow core wall panels with insulation, precast solid wall panels etc. Which is a smooth surface, lightweight and non-deforming after installation. It is a new-type non-loading bearing material. With good fire prevention, moisture-proof, good sound insulation, heat insulation used as partition wall panel and exterior wall panel.

Feature

1. Lightweight concrete wall panel battery mould machine mainly uses lightweight aggregate (expanded perlite, ceramsite, shale, EPS particles, volcanic ash, etc.), cementitious materials (cement, gypsum, magnesite cement, etc.), fillers (fly ash, slag, sand,plant fiber, tailings, construction waste, etc.), reinforcement materials (glass fiber, steel wire, plastic steel, etc.), and foaming agent to produce foamed concrete. Using different raw materials, the weight, strength, sound insulation and heat preservation performance of wall panels will be different. Main use: used for internal and external wall of frame structure house, boundary wall, and fence wall.

2. Multiple-use of one machine. By changing spares, one machine can produce lightweight hollow core wall panel(round holes or square holes), solid wall panel, EPS sandwich wall panel, GRC wall panel, insulated sandwich wall panel, etc.

3. The Lightweight wall panel battery mould machine can be manual, semi-automatic, automatic according to the customer’s production requirements and investment budget.

4. With less manpower, small plant area, flexible and mobile, it can be used for site production.

Raw materials

- Cement: Portland cement: Curing time is 8-10hours, Low alkali sulphoaluminate cement(Quick setting):2hours

- Flyash: It can be replaced by fine sand, quarry dust, fine slags etc.

- Foaming agent: Foaming agent is a surfactant, in water by stirring to form a foam, foam and slurry stirred.

- Fiber glass mesh: Width:600mm, Hole size:10x10mm, Weight: min.80g/m2

Wall Panel Specification

Size (mm) Pcs/Mould Weight 3000x600x90 20 42kg/m2 3000x600x100 20 46kg/m2 3000x600x120 15 56kg/m2 3000x600x150 12 70kg/m2 3000x600x180 10 84kg/m2 3000x600x200 10 93kg/m2 Lightweight wall panel battery mould machine specification

Annual output 20 panels per moulds(90mm) Hydraulic power 4 KW Hydraulic pressure 5 Mpa Machine size 3.5*2.8*1.3m Machine weight 6000kg Product width 600mm Partition steel plates Q235, thickness 5mm Steel plates leveling tolerance ≤1mm Product length Can be adjustable within 3000m Moving motor power 4KW