Графит с высокоуглеродистым покрытием плавильный кастинговый тигли 2 кг 5 8 30

- Категория: Graphite Crucible >>>

- Поставщик: Zibo,Yinxuan,Carbon,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.0 $* | 0.39 $* |

| Aug-15-2025 | 0.23 $* | 0.79 $* |

| Jul-15-2025 | 0.98 $* | 0.80 $* |

| Jun-15-2025 | 0.43 $* | 0.97 $* |

| May-15-2025 | 0.15 $* | 0.37 $* |

| Apr-15-2025 | 0.65 $* | 0.0 $* |

| Mar-15-2025 | 0.21 $* | 0.31 $* |

| Feb-15-2025 | 0.65 $* | 0.96 $* |

| Jan-15-2025 | 0.58 $* | 0.3 $* |

Характеристики

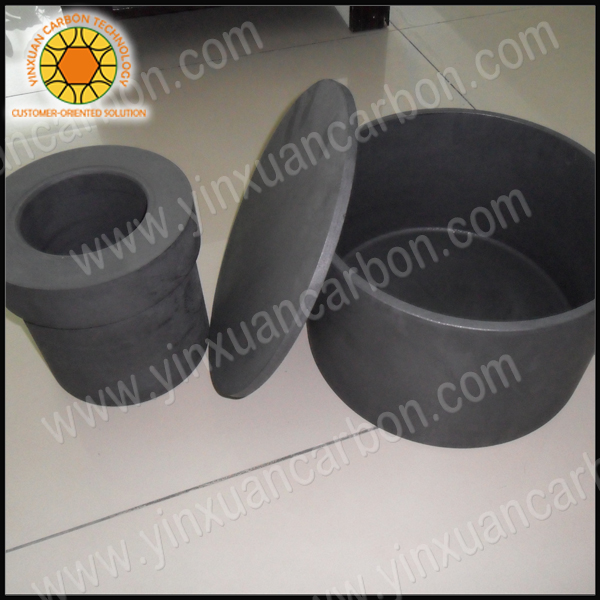

High Carbon 2KG 5KG 8KG 30KG 100KG Coating Graphite Melting Casting Crucibles

Graphite crucible is mainly used isostatic graphite, molded graphite, fine grain size graphite material . it has properties of high strength, high density, high purity, heat - resistance, anti-abrasion, anti - scour, anti - oxidation , anti - impact and anti - thermal shock

Average grain size | Bulk Density | Specific Resistivity | Flexcural Strength | Compressive Strength | Elastic Modulus | C.T.E | ASH | |

| Unit | MM | g/cm^3 | μΩ.m | MPa | MPa | GPa | *1/10^6 /℃ | % |

| GSK-Ⅰ | ≤0.8 | ≥1.69 | ≤10.0 | ≥14.0 | ≥30.0 | ≤11.0 | ≤3.0 | ≤0.3 |

| GSK-Ⅱ | ≤0.8 | ≥1.72 | ≤7.5 | ≥15.0 | ≥34.0 | ≤9.0 | ≤3.0 | ≤0.3 |

| TSK-Ⅰ | ≤2.0 | ≥1.68 | ≤10.5 | ≥11.0 | ≥23.0 | ≤9.0 | ≤2.5 | ≤0.3 |

| TSK-Ⅱ | ≤2.0 | ≥1.72 | ≤8.0 | ≥15.0 | ≥32.0 | ≤11.0 | ≤2.5 | ≤0.3 |

| PSK-Ⅰ | ≤4.0 | ≥1.58 | ≤11.0 | ≥10.0 | ≥20.0 | ≤8.0 | ≤2.0 | ≤0.3 |

| PSK-Ⅱ | ≤4.0 | ≥1.72 | ≤8.5 | ≥13.0 | ≥28.0 | ≤6.0 | ≤2.0 | ≤0.3 |

| HPM-Ⅰ | ≤0.045 | ≥1.70 | ≤11.0 | ≥25.0 | ≥50.0 | ≤9.0 | ≤2.8 | ≤0.1 |

| HPM-Ⅱ | ≤0.045 | ≥1.78 | ≤10.0 | ≥30.0 | ≥60.0 | ≤9.5 | ≤3.0 | ≤0.1 |

| HPM-Ⅲ | ≤0.045 | ≥1.85 | ≤9.0 | ≥35.0 | ≥70.0 | ≤10.0 | ≤3.2 | ≤0.1 |

| ISO-Ⅰ | ≤0.025 | ≥1.70 | ≤15.0 | ≥28.0 | ≥56.0 | ≤9.5 | ≤3.2 | ≤0.07 |

| ISO-Ⅱ | ≤0.025 | ≥1.75 | ≤15.0 | ≥35.0 | ≥70.0 | ≤10.0 | ≤3.8 | ≤0.07 |

| ISO-Ⅲ | ≤0.025 | ≥1.80 | ≤14.0 | ≥37.0 | ≥75.0 | ≤10.5 | ≤4.2 | ≤0.07 |

| ISO-IV | ≤0.025 | ≥1.85 | ≤13.0 | ≥42.0 | ≥85.0 | ≤11.0 | ≤4.5 | ≤0.07 |

The different material in the table is available , and we have kinds of graphite to meet your requirement,.

According to different application conditions, the most suitable graphite material will be chosen for machining graphite crucible and graphite boat/dish, in order to get the optimal cost-efficient solution.

based on different technical requirement ,inorder to improve application effect and extend service life of graphite crucible and boat/dish, we could apply selective treatments to the products such as anti-oxidantion impermeability or strengthening treatments.

1. Non-ferrous metal casting , Mainly used in casting copper, brass, bronze , gold or sliver , glass smelting ,Aluminium smelting ,etc.

2,Used in other similar condition ,for example as a container, in high tempreture

Normally ,we receive clients' drawings and produce the products as clients' requirement

Also you can mail to us your sizes , for example wideth ,thickness,length, or even a sketch ,we can design it for you and when you think it is workable ,then we can produce it.

1,Surface special treatment, increase of service life

2,Has higher hardness,it is anti-friction

3,High pure, less impurity can ensure the molten copper property ,and make the copper surface have less scratches.

4,Mirror polish treatment

5,We have different grade graphite material ,can meet your different requirement.

- Customize production

- Close after-sales service

- Graphite application consultation, Technical support

- Drawing CAD and solidworks Design

- Experienced engineers to offer solution for improving cost efficienty of graphite products

- Aluminum and aluminum alloys smelting application: graphite degassing rotor, graphite baffle plate, graphite mould, graphite crucible, graphite plate, graphite spout, graphite launder.

- Copper, brass, bronze casting application: graphite dies, graphite mould, graphite tubes, graphite pipes, graphite rods, graphite sleeves, graphite box, graphite crystallizer etc.

- Other non-ferrous metal casting applied graphite parts.

- Various industrial furnaces applied graphite heating units, elements and furnace structural parts. Industries include but not limited to Phtovoltaic, solar energy, semi-conductor, ceramic, boron carbide, boron nitride industries etc.

- Hard alloys, diamond tools sintering application: graphite boat, graphite disc, graphite plate, graphite sintering molds, graphite crucible, graphite heating elements etc.

- Rare earth, precious metal casting application: graphite crucible, graphite anodes, graphite rods, graphite heating elements etc.

- Chemical application: graphite heater exchanger, graphite electrode for electrolysis, graphite rod.

- Glass smelting application: graphite mold, graphite plate, graphite rods etc.

- Machinery casting application: graphite densener, graphite rod, graphite brick, graphite chilling block etc.

- Vaccum evaporation application: graphite crucible. for producing metallic yarns, plastic packing materials etc.

- Other metal casting, foundry, smelting application: graphite rod, graphite plate, graphite tube, graphite pipe, graphite crucible, graphite mold, graphite block etc.

We have different grades of graphite material available in stock, and capable of customize production according to customers' drawings. So tell us your rough idea or drawings, we will make it come true.