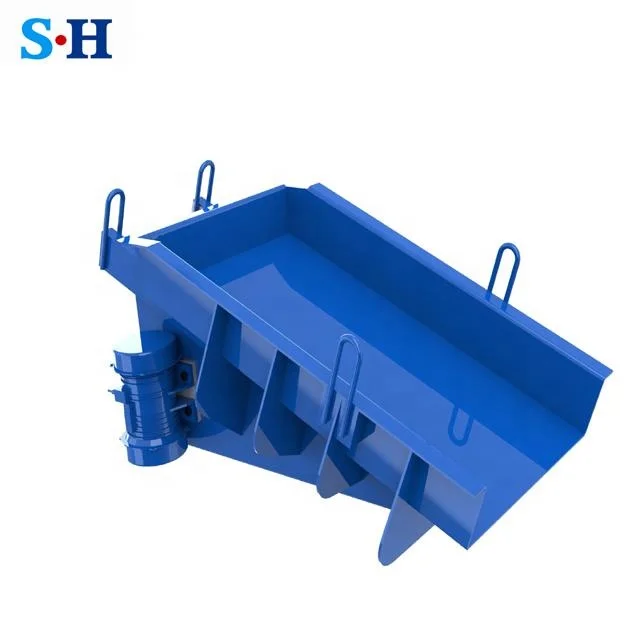

Вибрационный питатель для горных

- Категория: Всасывающий рукав для добычи >>>

- Поставщик: Xinxiang,Shanhe,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 893.94 $* | 938.90 $* |

| Aug-16-2025 | 885.76 $* | 929.39 $* |

| Jul-16-2025 | 743.40 $* | 780.7 $* |

| Jun-16-2025 | 870.0 $* | 914.42 $* |

| May-16-2025 | 758.14 $* | 796.96 $* |

| Apr-16-2025 | 855.11 $* | 898.20 $* |

| Mar-16-2025 | 848.88 $* | 890.1 $* |

| Feb-16-2025 | 840.90 $* | 882.52 $* |

| Jan-16-2025 | 833.13 $* | 875.64 $* |

Характеристики

vibrating feeder features:

(1) Small cubage, light weight, simple structure, easily fixed no movement assembly, no lubricate, maintain easily.

(2) Electric Magnetic feeder uses up electric energy less, because of the engine vibrating resonance principle and double plastid works at the low critical nearly resonance.

(3) Because it can change and start or off material flow instantaneously, the feeding size is higher accuracy.

(4) Control equipment of this series Electric-Magnetic Vibrating Machine uses the controlled silicon half wave whole line, in the use, according to adjusting controlled opened corner easily to adjust the feeding size, achieve the produce line is controlled by concentrating automatically.

(5) Because the material that in the chute is continuously thrown when feeding, and along the track of parabola moves bound toward, the damage of chute feeder is little.

(6) This series Electric-Vibrating Feeder is not suitable for the flameproof conditions.

Technical specifications:

Model No. | Feeding capacity (t/h) | Max. feeding size | Double amplitude (mm) | Voltage (V) | Electric current | Power | Weight | |

Level angle | -10° angle | |||||||

GZ-0 | 5 | 7 | 50 | 1.75 | 220 | 1.34 | 0.06 | 50 |

GZ-1 | 10 | 20 | 50 | 3 | 0.15 | 95 | ||

GZ-2 | 25 | 35 | 75 | 4.6 | 0.25 | 140 | ||

GZ-3 | 35 | 50 | 85 | 6.8 | 0.35 | 220 | ||

GZ-4 | 50 | 70 | 100 | 8.4 | 0.45 | 330 | ||

GZ-5 | 100 | 140 | 150 | 12.7 | 0.65 | 560 | ||

GZ-6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 1.5 | 1150 |

GZ-7 | 250 | 350 | 250 | 24.6 | 3 | 1820 | ||

GZ-8 | 400 | 560 | 300 | 39.4 | 4 | 2950 | ||

GZ-9 | 600 | 840 | 350 | 47.6 | 5.5 | 3650 | ||

GZ-10 | 1000 | 1400 | 500 | 47.6×2 | 5.5×2 | 7580 | ||

Packing:Outer packing is plywood case, which is up to the international standard. Inner packing is moisture-proof and water-proof membrane. All of packages are wrapped by 0.5mm steel belt to further strengthen, which can ensure machine safe during shipping.

Shipping: By Sea:To Europe, it needs around 40days; To South-East, it needs around 15days, To Middle-East, it needs around 35days, To North America, it needs around 30days, To Middle America, it needs around 45days; To South America, it needs around 45days;

By Air: it needs around 5days to 10days;

By Train: it only can reach Middle-Asia, Russia, Europe and so on, usually, it needs 3days to 15days.

By Truck: it only can reach South-East,usually, it needs around 5days to 10days.

Our company owns 20years of design and manufacture experiences and obtains a top qualified personnel who are leading local on Rotary Vibrating Screen; Linear Vibrating Sieve; Gyratory Screen;Ultrasonic Vibrating Screen; Tumbler Screen Machine; Banana Screen; Laboratory Test Sieve; Hand-Held Ultrasonic Lab Test Sieve; High Frequency Sieve; Direct Discharging Screen;Vibration Table; Vibrating Feeder;

Flexible Screw Conveyor; Belt Conveyor; Bucket Conveyor; Vertical Feeder; Vacuum Feeder; Mill; Vacuum Dryer; Mixer; Colloid Mill;,With professional personnel, we always endeavor to become the leading supplier with professional service and the best solution to Food industry; Medicine industry; Chemical industry,Metal&Metallurgy Mining industry; Ceramic industry;Social pollution disposed and other industrial materials.

With the motto of "quality assurance & long-term commitment", we are committed to supplying product with right, consistent quality and perfect service which satisfies customers. This is exactly what makes the values of consistency, integrity and business ethic of our company.