Геомембрана сварочная машина для HDPE LDPE гидроизоляционный

- Категория: Аппараты для сварки пластика >>>

- Поставщик: The,Best,Project,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 774.61 $* | 813.5 $* |

| Aug-15-2025 | 767.83 $* | 805.8 $* |

| Jul-15-2025 | 644.49 $* | 676.71 $* |

| Jun-15-2025 | 754.33 $* | 792.89 $* |

| May-15-2025 | 657.1 $* | 690.39 $* |

| Apr-15-2025 | 741.67 $* | 778.95 $* |

| Mar-15-2025 | 735.4 $* | 772.13 $* |

| Feb-15-2025 | 728.99 $* | 764.20 $* |

| Jan-15-2025 | 722.93 $* | 758.76 $* |

Характеристики

Geomembrane Welding Machine for HDPE LDPE Waterproofing Material

geomembrane hot wedge welder can weld geo-membrane of various thickness and are applicable for welding of all thermal-fused material such as PVC, HDPE, EVA, PP and so on.

The control of this series of welding machine adopts PID automatic thermostatic control with high control accuracy and low temperature fluctuation; speed control adopts PWM automatic voltage and speed regulation circuit, driven by DC servo motor, with great output torque and the operating is stable.

This series of welding machine is excellent in performance and easy for operating, with high welding speed and good work quality. It is extensively used in engineering projects such as expressways, tunnels, reservoirs, waterproof of construction and so on.

Technical parameters

Product | Welding machine/ hot wedge welder |

Model | BPM 800 |

Description | * Voltage (V): 220V |

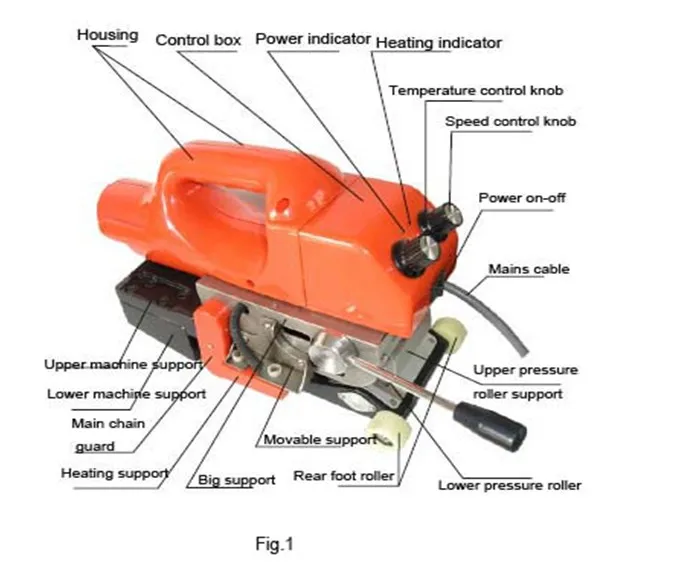

Main Components

Operation principle

Motor drives upper and lower pressure rollers to rotate through reduction gearbox and chain. Slide carriages drive the hot wedge and insert it between the two base materials, at the same time lever presses pressure rollers and engages the two fused base materials.

General troubles and eliminations

Motor not run

| Power off | Check that the mains is in On condition |

Fuse damaged | Replace fuse | |

Speed control circuit board damaged | Replace speed control circuit board or control box assembly | |

Motor burned | Replace motor | |

Motor speed can’t be regulated

| Speed control knob is loosened | Tighten speed control knob |

Power tube disruption | Replace power tube or control box assembly | |

Hot wedge do not heat

| Tubular electric heating element damaged | Replace hot wedge assembly |

Thermocouple failure | Replace thermocouple | |

Temperature control knob loosened | Tighten temperature control knob | |

Temperature control circuit board damaged | Replace temperature control circuit board or control box assembly | |

Hot wedge is burned red

| Thermocouple failure | Replace thermocouple |

Controlled silicon disruption | Replace controlled silicon or control box assembly | |

Chain jumping | There may be sand or small stones on chain and gear | Remove sand or small stones |

Maintenance

The complete machine should be cleaned, greased and placed in a dry place if it is not used.

For PVC welding, the adhesions on hot wedge should be cleaned off if it is not used longer than 4 hours to prevent wedge corrosion and service life being shortened.

Recommend: for welding of material that corrosive gas may be produced after hot fusing such as PVC and the like, stainless steel hot wedge (optional accessory) is preferred for extending of service life.

Supplied accessories

Protector tube 4A 2 pcs

1A 2 pcs

Cross rubber pad for coupling 1 pcs

Philips driver 1 pcs

Inner hexagonal spanner 3 pcs

Silica gel wheel 1 pair

The Best Project Material Co., Ltd (BPM) is the leading geomembrane manufacturer, supplier, wholesaler and exporter. Our main innovative products include Smooth Geomembrane HDPE Liner, Textured HDPE Geomembrane, Composite Geomembrane Liner and other geosynthetics, etc. All of them had been certificated by the ISO9001, ISO14001, Soncap, SASO and BV certificates and passed SGS and Intertek test.

Q1:Are you a trader or manufacturer?

A:We are manufacturer,we have our 100% self-owned factory in Shandong.

Q2:What's your delivery time?

A:It depends on you order item and quantity,usually 10-20 days.

Q3:What's the payment?

A:T/T,Western Union,Paypal,L/C...

Q4:If I still want to know more information?

A:Please email me to yuvia(at)hdpetgm.com. I will help you.