China factory price ldpe/lldpe/hdpe/mdpe/eva

- Категория: Plastic Granulators >>>

- Поставщик: Nanjing,Cowin,Extrusion,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 4760.72 $* | 4998.74 $* |

| Aug-16-2025 | 4720.50 $* | 4956.31 $* |

| Jul-16-2025 | 3960.13 $* | 4158.93 $* |

| Jun-16-2025 | 4640.28 $* | 4872.89 $* |

| May-16-2025 | 4040.27 $* | 4242.55 $* |

| Apr-16-2025 | 4560.6 $* | 4788.25 $* |

| Mar-16-2025 | 4520.30 $* | 4746.95 $* |

| Feb-16-2025 | 4480.7 $* | 4704.24 $* |

| Jan-16-2025 | 4440.77 $* | 4662.91 $* |

Характеристики

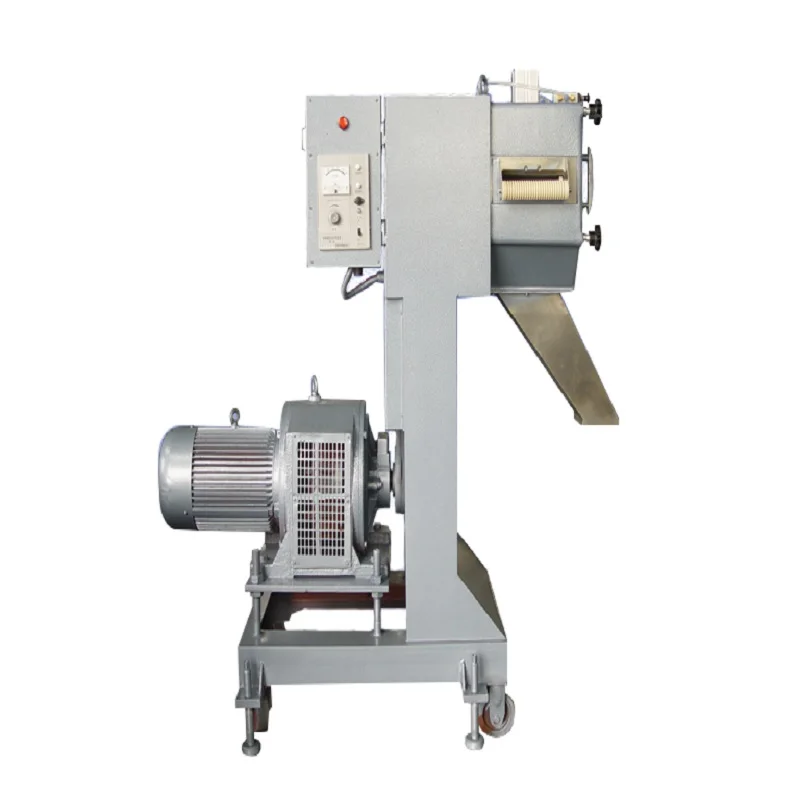

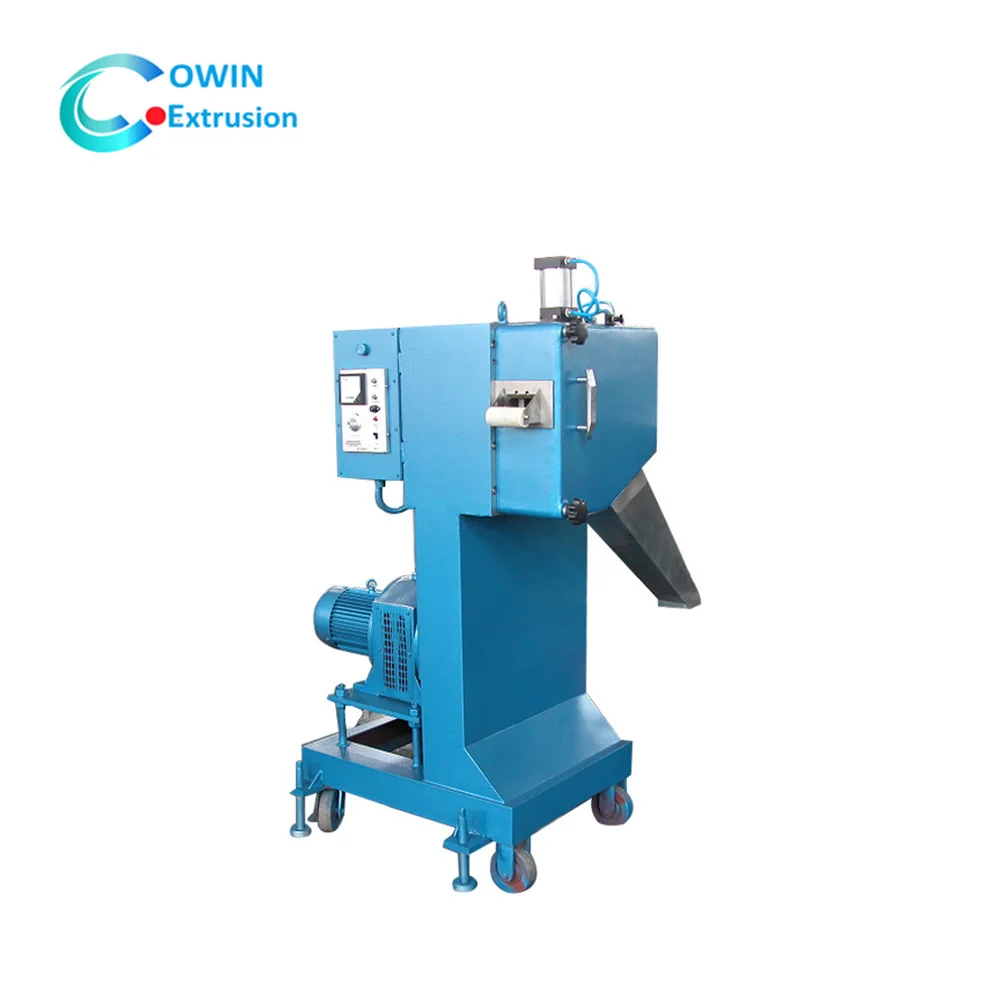

It is strand pelletizing (cold cut): melt coming from a die head is converted into strands that are cut into pellets after cooling and solidification.

A line utilizing a simple water bath for strand cooling often is the first option for compounding plants. However, the individual layout can vary significantly, due to the demands of throughput, flexibility, and degree of system integration. In strand pelletizing, polymer strands exit the die head and are transported through a water bath and cooled. After the strands leave the water bath, the residual water is wiped from the surface by means of a suction air knife. The dried and solidified strands are transported to the pelletizer, being pulled into the cutting chamber by the feed section at a constant line speed. In the pelletizer, strands are cut between a rotor and a bed knife into roughly cylindrical pellets. These can be subjected to post-treatment like classifying, additional cooling, and drying, plus conveying.

Granulator is for compounding extrusion and glass fiber reinforced water-cooled granulation system.

It can be independently used to make various Plastic Cold brace and Fiberglass, such as, polyolefin’s, engineering plastics, and PP, PBT, PET into granules. It revolves slowly and so its noise is low. Besides, its granules are neat. Compared with similar products, power consumption reduces 30%, so it greatly saves energy.

The machine has a constant power, ensuring that it works at any speed, which can greatly reduce the unnecessary waste of precious raw materials.

SPECIFICATION

name | model number | ||||||||

LQ-25 | LQ-60 | LQ-100 | LQ-200 | LQ-300 | LQ-400 | LQ-500 | LQ-600 | LQ-900 | |

Maximum output Kg/h | 25 | 60 | 100 | 200 | 300 | 400 | 500 | 600 | 900 |

Input number strip | 3 | 4 | 6 | 12 | 15 | 25 | 25 | 32 | 42 |

The size of a granule (mm) | |||||||||

Electrical machinery power (KW) | 0.75 | 1.1 | 1.5 | 3 | 3 | 4 | 5.5 | 7.5 | 11 |

Commissioning service includes supervision of installation and start-up, on-site training. Service charges are free.

· Free technical service and technical consultation should be adhered to before, during and after sales.

· Provide a complete set of technical information (including electrical schematic diagram, wiring diagram, outsourced parts instructions, product use instructions, etc.).

· Provide unit production process layout drawing, main screw assembly drawing, transmission box overhaul drawing;

· With the change of processing materials and processes and the development of new products, the corresponding screw assembly drawing and various technical consultation are provided free of charge.

· The equipment is guaranteed free of charge for one year. After the expiration of the warranty period, we still insist on after-sales service, spare parts only charge the cost price.