Многофункциональные гранулы из пластика

- Категория: Plastic Granulators >>>

- Поставщик: Henan,Frien,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.29 $* | 0.3 $* |

| Aug-15-2025 | 0.47 $* | 0.92 $* |

| Jul-15-2025 | 0.79 $* | 0.9 $* |

| Jun-15-2025 | 0.49 $* | 0.30 $* |

| May-15-2025 | 0.40 $* | 0.6 $* |

| Apr-15-2025 | 0.41 $* | 0.67 $* |

| Mar-15-2025 | 0.46 $* | 0.13 $* |

| Feb-15-2025 | 0.7 $* | 0.35 $* |

| Jan-15-2025 | 0.87 $* | 0.61 $* |

Характеристики

Product Description

Product introduction

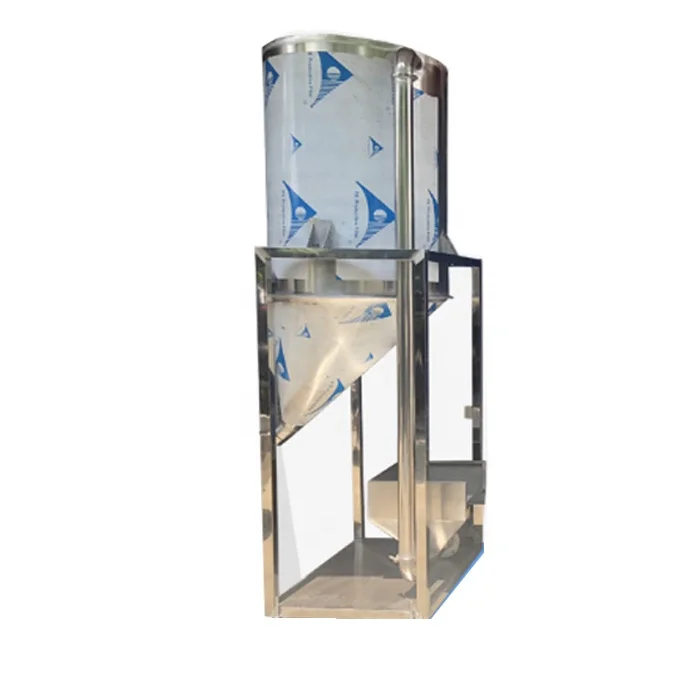

It is designed for producing granules from recycled PP/PE film, scraps. This plastic pelletizing machine is composed by extruder,die, pelletizer, cooling system, vibrate sieve etc.According to different material, we have various plastic pelletizing machine like single/double stage plastic pelletizing line, strand pelletizing/water-ring pelletizing, force feeder or crushing feeder type

pelletizing line.With years experience of plastic pelletizing machine, we can meet clients different needs.

pelletizing line.With years experience of plastic pelletizing machine, we can meet clients different needs.

Plastic recycling plastic pellet machine :

Many materials can be processed directly without need of the upstream preshredding,resulting in a dramatic reduction in operational costs.Less power consumption cost per kilogram,high throughput,reduced floor space occupation and operator

attendance.Applicable plastic materials: PP, HDPE, LDPE,LLDPE,TPV,EVA,ABS and PS,etc

attendance.Applicable plastic materials: PP, HDPE, LDPE,LLDPE,TPV,EVA,ABS and PS,etc

Product Paramenters

Plastic pellet machine | ||||||||

Model | Output | Power | Weight | Inlet diameter | ||||

FR-180 | 300kg/h | 0-120kw | 600kg | 0-280mm | ||||

Number of rotating knife | Heating power | Screw the number | Length of the screw | Screw diameter | ||||

0-10pcs | 60-80kw | single screw | 200mm | 150mm | ||||

The Parameter of Crusher | ||||||||

Model | FR-500 | FR-600 | FR-800 | FR-1000 | ||||

Crushing capacity | 600-900 | 800-1200 | 1500-2500 | 2000-4000 | ||||

screw diameter | 100 mm | 130mm | 150mm | 180mm | ||||

Power | 22kw | 30kw | 45kw | 55kw | ||||

Size | 500*1700mm | 600*1700mm | 800*1800mm | 1000*1800mm | ||||

Weight | 500kg | 800kg | 2000kg | 3000kg | ||||

Details Images

1. Unique design, simple structure, multifunction, and easy to operate.

2. Multi-purpose, it can crush and recycle agglomerate materials, reclaimed materials and waste.

3. TYPE C applies unique dust beads separating agency, it can separate the dust from the beads.

2. Multi-purpose, it can crush and recycle agglomerate materials, reclaimed materials and waste.

3. TYPE C applies unique dust beads separating agency, it can separate the dust from the beads.

1. Use for EPS, XPS recycling into beads and hot melting.

2. High pressure compacting, fast melting, drain air and extruding felting.

3. Processing: Crushing, first time extruding, second extruding, via net, via water tank cooling, cut beads, natural drying or oven drying.

2. High pressure compacting, fast melting, drain air and extruding felting.

3. Processing: Crushing, first time extruding, second extruding, via net, via water tank cooling, cut beads, natural drying or oven drying.

The equipment is mainly used for granulation of all kinds of recycled plastics.The equipment is composed of the main machine, mould, granulator and cooling trough (or air cooling equipment). The complete set of units can be automatically continuous production, direct granulation, and granulation clean, pollution-free and aging phenomenon, greatly reduce the production cost and improve the production efficiency.The machine has the remarkable characteristics of small size, high efficiency, good performance, low power consumption, high finished product quality and wide adaptability.

1.unit include:extrusion granulating machine, heating system, power distribution box,cooling tank, and cutter. The machine can produces continuously and only needs one person to operate.

2.The machine are automated from feeding materrials to discharging particles.

3.Make full use of high friction uninterrupted heating system, automatic heating production,avoiding continuous heating and saving energy.

4.Using full automatic power distribution system to ensure the normal operation of the motor.

2.The machine are automated from feeding materrials to discharging particles.

3.Make full use of high friction uninterrupted heating system, automatic heating production,avoiding continuous heating and saving energy.

4.Using full automatic power distribution system to ensure the normal operation of the motor.

Product Feature

Materials of the plastic granule raw material machine extruder machine plastic recycling plastic pellet machine :

1.Screw barrel are made of 40Cr imported high strength and high quality, durable in use. 2.Appearance of the machine is beautiful and generous. Based on customer requirements, color is customized. 3.The machine adopts ZLYJ series hardened reducer, no noise , maintenance free and long service life. 4.The machine is equipped with quick net changing device, convenient and efficient. 5.The machine is equipped with one hob cutting machine by electromagnetic speed-regulating and has low noise, hob can't be abrasive within 1000t.

Our Servise

Our Service :

Pre-sale Service

1.Supply item design, process design.

2.Help you to chose the fittest machine.

3.Making a machine according to your requirement.

After Service

1.If you have any problems, contact us, we will solve the problems as soon as possible .

2.Free repair whole using life, Quality guarantee term is for one year. Malfunctions which are caused by machine-self and quality will be responsible for our manufacturer. Other malfunctions which are caused by operation mistakes, man-made problems, etc will be responsible for clients-self(without the freight and accessories charge).

1.Supply item design, process design.

2.Help you to chose the fittest machine.

3.Making a machine according to your requirement.

After Service

1.If you have any problems, contact us, we will solve the problems as soon as possible .

2.Free repair whole using life, Quality guarantee term is for one year. Malfunctions which are caused by machine-self and quality will be responsible for our manufacturer. Other malfunctions which are caused by operation mistakes, man-made problems, etc will be responsible for clients-self(without the freight and accessories charge).

Package And Transport

WOOD PACKAGE

In order to keep safte and keep good qualit of our proudcts, before delivery, we will pack the goods by wood container which can protect products.

SHIPPING

1.We can load container at:qingdao,tianjin,guangzhou etc.

2. Shipping method:Courier service,Air transport,Sea Transport

3.Can accept oder:Full container cargo load,Less container load

4.Our service:FOB,CIF,Door to Door etc.

5.We always choose the most economical and reliable shipping company to make sure you receive the goods in time.

6.The tracking number will be provided to you once the consignment is shipped.

In order to keep safte and keep good qualit of our proudcts, before delivery, we will pack the goods by wood container which can protect products.

SHIPPING

1.We can load container at:qingdao,tianjin,guangzhou etc.

2. Shipping method:Courier service,Air transport,Sea Transport

3.Can accept oder:Full container cargo load,Less container load

4.Our service:FOB,CIF,Door to Door etc.

5.We always choose the most economical and reliable shipping company to make sure you receive the goods in time.

6.The tracking number will be provided to you once the consignment is shipped.