Машина для производства гипсокартонных

- Категория: >>>

- Поставщик: Linyi,Yuanteng,International,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 35700.97 $* | 37485.10 $* |

| Aug-15-2025 | 35400.67 $* | 37170.50 $* |

| Jul-15-2025 | 29700.45 $* | 31185.49 $* |

| Jun-15-2025 | 34800.71 $* | 36540.94 $* |

| May-15-2025 | 30300.83 $* | 31815.76 $* |

| Apr-15-2025 | 34200.27 $* | 35910.85 $* |

| Mar-15-2025 | 33900.73 $* | 35595.15 $* |

| Feb-15-2025 | 33600.90 $* | 35280.53 $* |

| Jan-15-2025 | 33300.94 $* | 34965.4 $* |

Характеристики

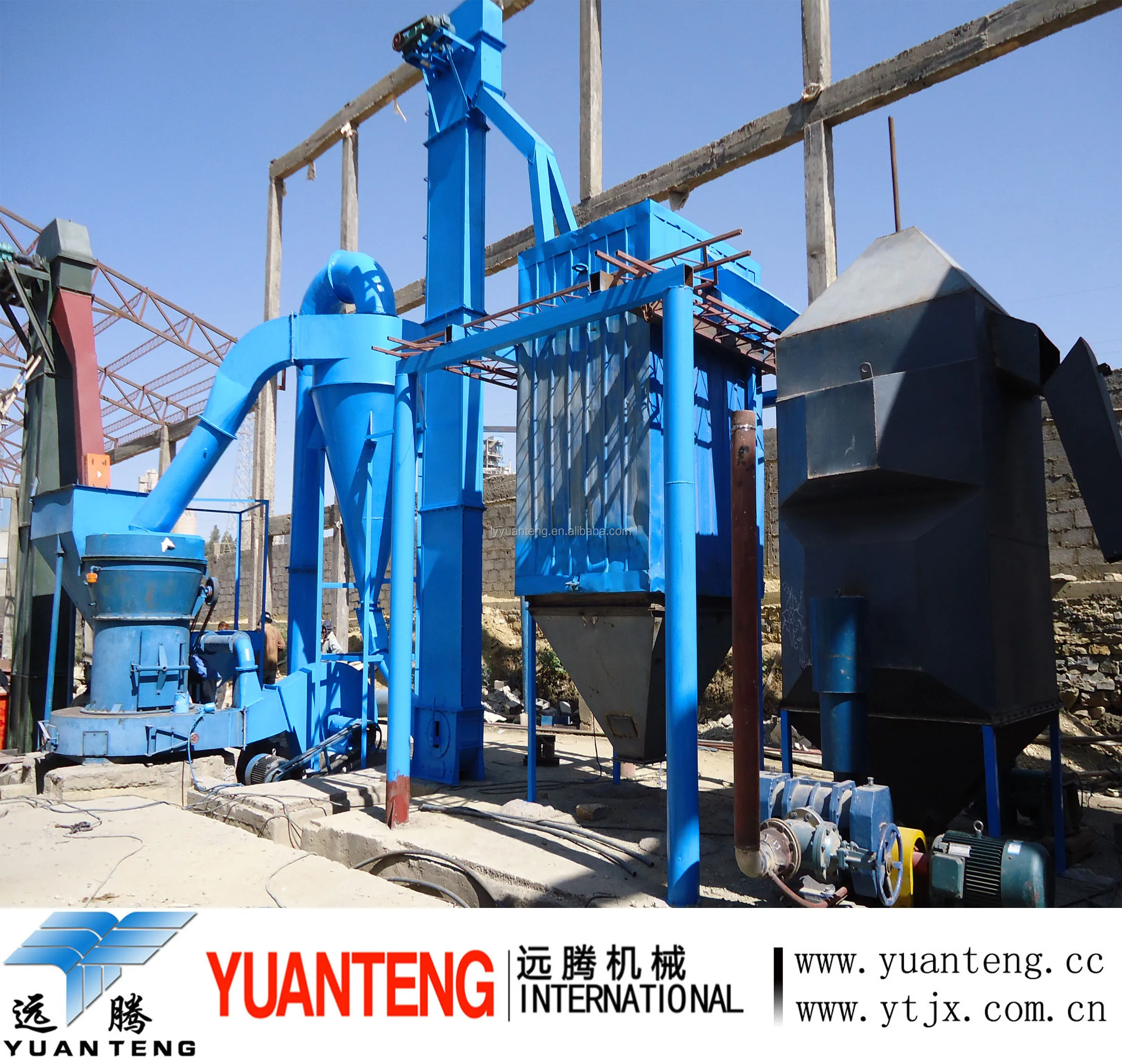

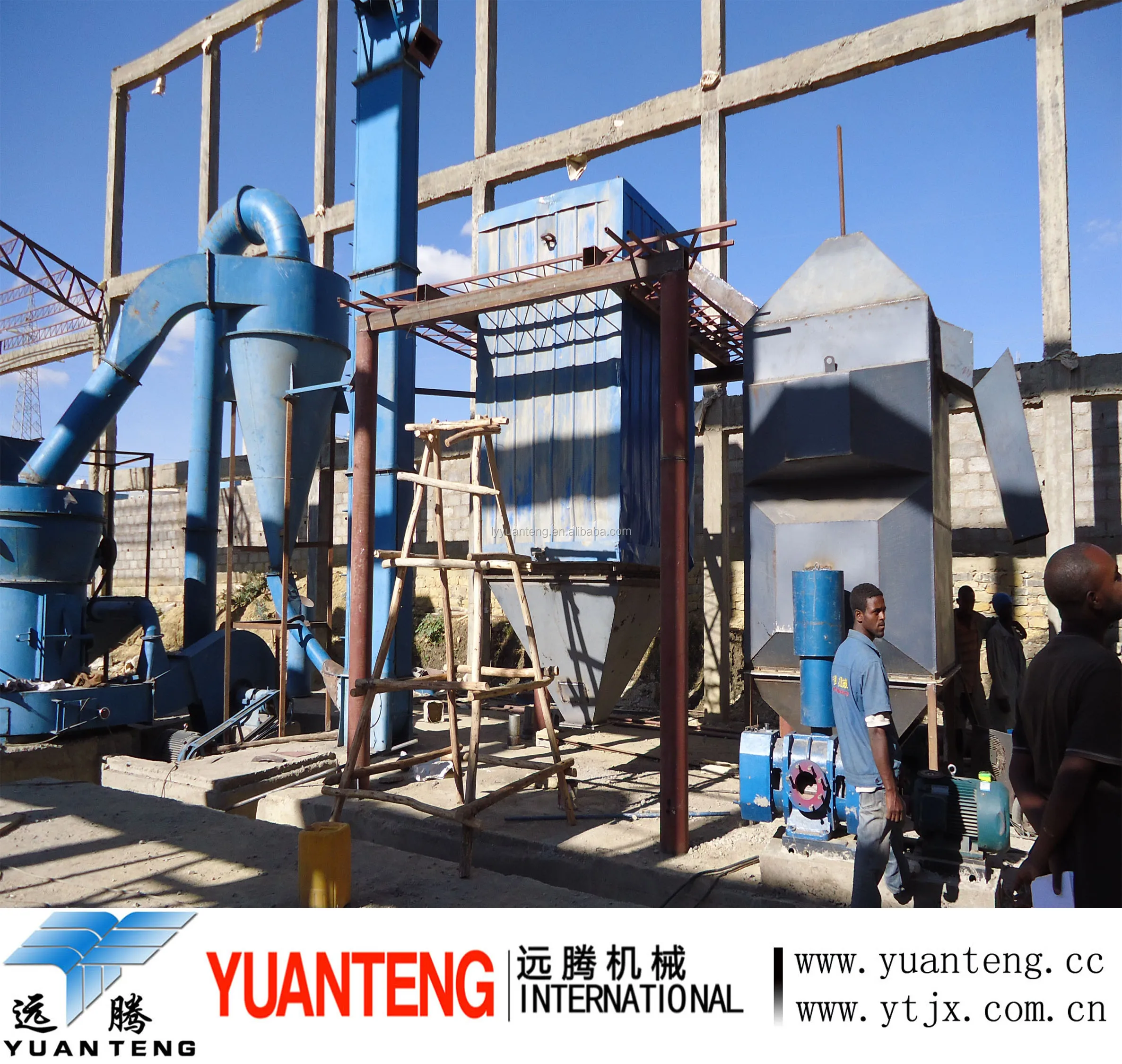

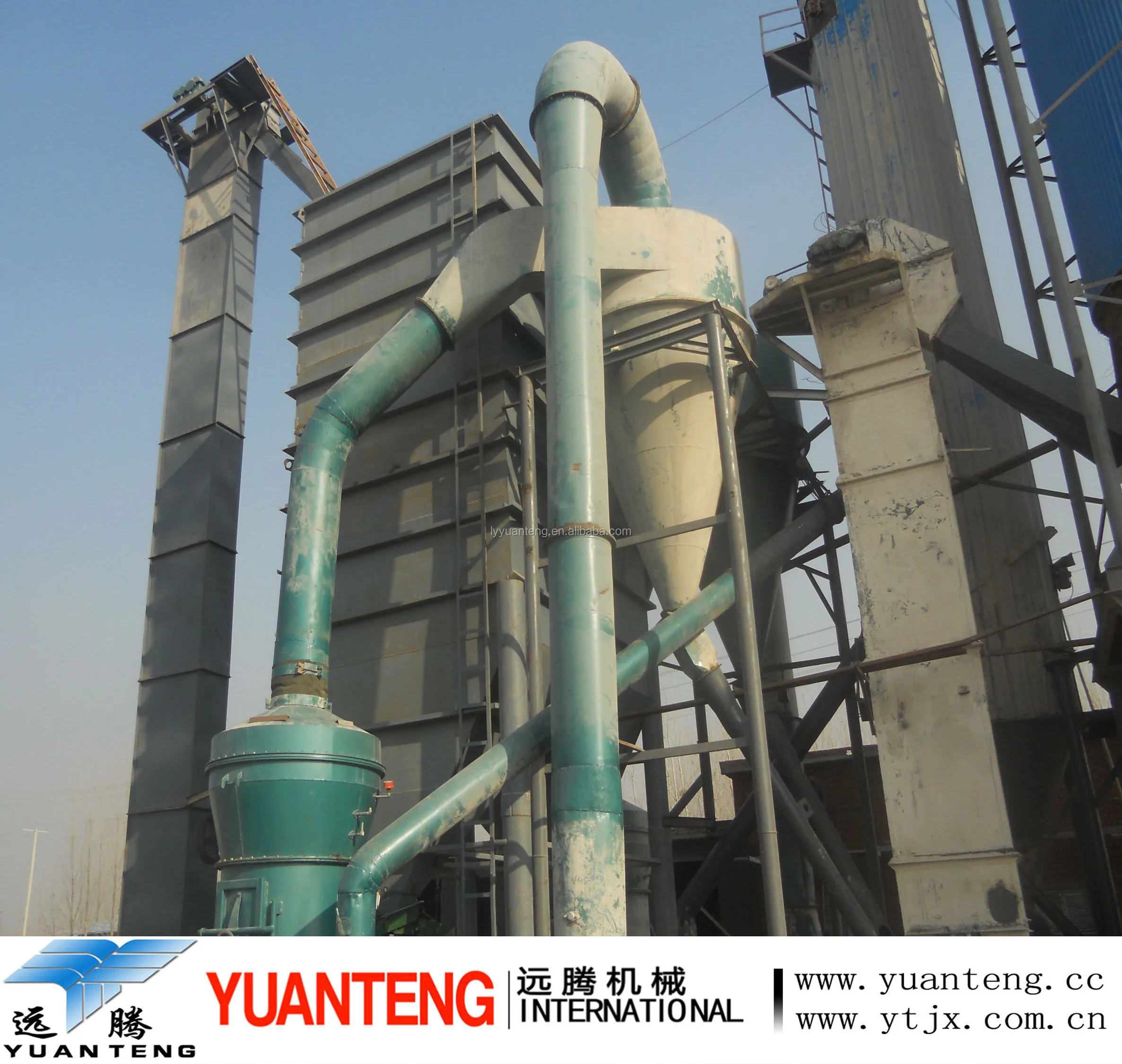

Gypsum powder production line brief introduction:

1. Brief introduction

Natural gypsum generally includes dihydrate gypsum and anhydrous gypsum. In order to get the valuable materials, generally, we get semi-hydrated gypsum through heating the dihydrate gypsum.

CaSO4·2H2O heating CaSO4·1/2H2O+3/2 H2O↑

It is the process.

The calcined semi-hydrated gypsum can widely be used for plasterboard, decoration board, gypsum block, stucco gypsum, and molding gypsum etc.

2. Production scale

10000 tons to 300000 tons /year

3. Main technology

A: fluidized furnace technology (calcine after grinding)

Gypsum mine →first breaking →second breaking →grinding →calcining →aging →finished products (CaSO4·1/2H2O )

B: Rotary kiln technology (calcine after grinding) or (grinding after calcine)

Gypsum mine →first breaking →second breaking →calcining →grinding →aging →finished products (CaSO4·1/2H2O )

4. Raw materials

Content of CaSO4·2H2O in gypsum mine >80%.

The grade of mine and the crystal configuration will influence the quality ofsemi-hydrated gypsum.

5. Main index

No. | Name | Unit | Index |

1 | Annual Capacity | Ton | 10000 to 300000 tons |

2 | Workdays/year | Day | 300 |

3 | Annual gypsum mine consumption | Ton |

|

4 | Power | Kw |

|

5 | Workshop area | m2 |

|

6 | Stock yard area(awning ) | m2 |

|

6. The list of the equipment

No. | Name | Unit | Quantity |

1 | Apron feeder | Set | 1 |

2 | Hammer crusher | Set | 1 |

3 | Bucket elevator | Set | 1 |

4 | Raw materials silo | Set | 1 |

5 | Mill | Set | 1 |

6 | Bucket elevator | Set | 1 |

7 | Fluidized furnace | Set | 1 |

8 | Electric dust collect | Set | 1 |

9 | Conveyor | Set | 1 |

10 | Bucket elevator | Set | 1 |

11 | Screw conveyor | Set | 1 |

12 | Single dust filter | Set | 4 |

13 | Single screw strobe | Set | 8 |

14 | Homogenization silo | Set | 4 |

15 | Discharger | Set | 4 |

16 | Screw conveyor | Set | 1 |

17 | Bucket elevator | Set | 1 |

18 | Package silo | Set | 1 |

19 | Single spout packer | Set | 1 |

20 | Roots fan | Set | 1 |

21 | Centrifugal fan | Set | 2 |

22 | Boiler | Set | 1 |

23 | Circulate pump | Set | 2 |

24 | Oiling pump | Set | 1 |

25 | Perch oil tank | Set | 1 |

26 | Low oil tank | Set | 1 |

27 | Air exchanger | Set | 1 |

28 | Power control cabinet | Set | 7 |

NOTE:

1). Detailed parameters shall be confirmed according to site conditions and buyer’s requests.

2). The buyer shall offer the wire, cable and electric apparatus fittings.

3). The sluice, guardrail, overhaul platform, ladder, support and so on will be made and installed after finishing equipment installation. All kinds of steel will be supplied by the buyer.

4). The technical process, process chart, circuit diagram will be supplied separately.

7. Process

Natural gypsum and chemical gypsum,different process,just for reference.