Б/у машина для переработки картриджей с тонером принтера/высокопроизводительная

- Категория: Waste Treatment Machinery >>>

- Поставщик: Henan,Province,Gongyi,City,East,China,Metallurgical,Coal,Mine,Machinery,Factory

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 7138.87 $* | 7495.0 $* |

| Aug-15-2025 | 7078.11 $* | 7432.46 $* |

| Jul-15-2025 | 5938.90 $* | 6235.42 $* |

| Jun-15-2025 | 6958.77 $* | 7306.56 $* |

| May-15-2025 | 6058.75 $* | 6361.64 $* |

| Apr-15-2025 | 6838.9 $* | 7180.48 $* |

| Mar-15-2025 | 6778.60 $* | 7117.63 $* |

| Feb-15-2025 | 6718.8 $* | 7054.39 $* |

| Jan-15-2025 | 6658.20 $* | 6991.53 $* |

Характеристики

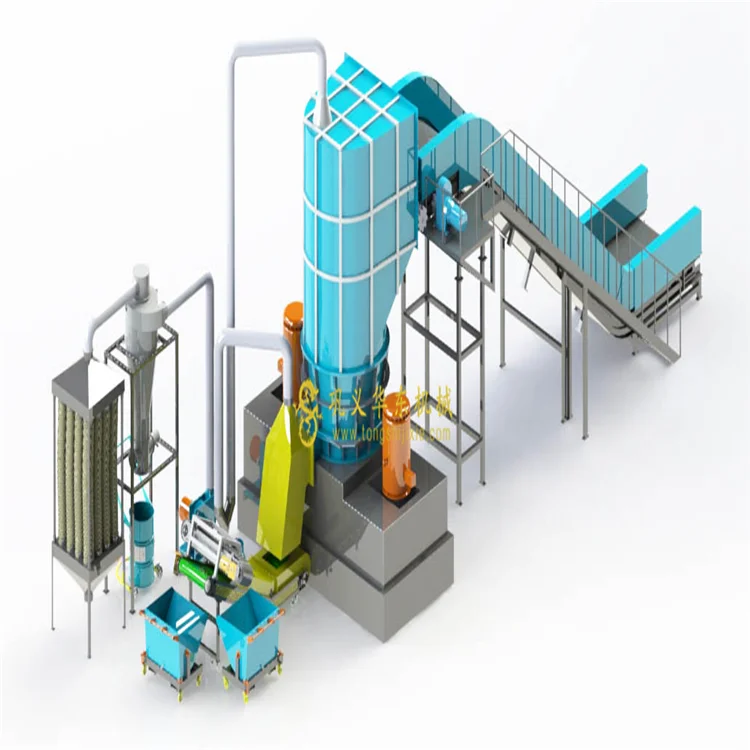

Used Printer Toner Cartridges Recycling Machine/high Performance Shredder Machine

Introduction of scrap metal recycling plant/line:

Waste steel Crusher is mainly used for cutting and crushing of scrap iron materials. Waste steel Crusher can achieve large size of scrap steel materials such as scrap metal, scrap steel, scrap iron, cans, scrap steel profiles, crush metal, wire ropes, scrap square pipes, iron slag, iron boxes, corner materials, plastic steel doors and windows, scrap cars, bicycle racks, paint drums, etc to become a small size ideal state. And complete pre-crushing, secondary crushing, molding, encryption, sorting. and waste recycling merchants, steel mills, subsidiary enterprises of steel mills, foundry factories, waste recycling enterprises, waste recycling enterprises, scrap metal recycling enterprises favorite this kind of scrap steel crusher.

Application of scrap metal recycling plant/line:

The waste iron and steel materials that have been beaten and compressed by waste iron and steel Crusher have many advantages such as complete phase, uniform size, clean removal, high brightness, good purity, and specific gravity of piles. It is very suitable for handling light, medium and heavy scrap steel, large components, mixed scrap steel, and low-quality scrap steel. The metal material after being cut and broken by a scrap steel Crusher has a high density and reduce metal compression processes. High solubility and high steel discharge rate, It meets the requirements of the steel mill for refined materials into the furnace, and also reduces the number of input, reduces the smelting electrode, shortens the dissolution time, and reduces the smelting process, saving customers a lot of production costs.

The scope of application of scrap metal recycling plant/line:

Waste iron and steel Crusher is suitable for all kinds of scrap iron and steel products, such as centralized crushing, forming, encryption, sorting, cleaning, etc..

1. waste metal, light and thin materials, cans, corner materials, packed metal, thin iron sheet, car shavings, iron boxes, iron shavings, iron boxes, paint drums, colored steel tiles, Gates;

2. scrap steel products, scrap steel, steel chips, corner steel, steel pipes, steel slag, steel bars, wire ropes, pipes, pipes;

3. metal waste: waste edge material, flush iron side material, plate side material, residue material, corner material, foot material, living waste;

4. aluminum alloy products, aluminum plate clasps, castings, valves, joints, doors and Windows, aluminum alloy shells, motor shells, engine cylinders, templates, cast aluminum parts;

5, scrap vehicles, used cars, crushed bodies, bicycles, motorcycles, wheels, chassis, keel strips, electric vehicles, automobile disassembled parts etc.

All other materials can be uniformly stored and concentrated to complete the purpose of scrap steel regeneration and crushing.

Type of scrap metal recycling line/plant:

1: Magnetic belt conveyor

Processing capacity(T / H): 1-30 speed adjustable

2: Dry powder magnetic separator

Processing capacity(T / H): 1-8 continuously adjustable

3: Iron removal machine

Processing capacity(T / H): 1-30 continuously adjustable

4: Wet magnetic separator

Processing capacity(T / H): 2-80 continuously adjustable

Composition of scrap metal recycling line/plant:

This sleeve is mainly composed of 1. chain plate conveyor; 2. roller teeth crushing device; 3. large material removing device; 4. scrap steel crushing host; 5. hydraulic open cover device; 6. hydraulic pressure station; 7. Pulse dust remover; 8. vibration separator; 9. magnetic selective conveyor; 10. discharge conveyor and other equipment composition.

Technical parameters of scrap metal recycling line/plant:

Model | Power(KW) | Scope of application | Processing capacity(t/h) | Measurement(mm) | Weight(t) | Input |

800 | 37-75 | Slight scrap steel with a thickness of less than 2mm, such as tin cans, paint barrel boxes, etc. | 0.8-1.5 | 2560*1800*2200 | 7.6 | 1000 |

900 | 65-150 | Various scrap steel that not less than 3mm in thickness | 3-6 | 4000*2300*2800 | 11.5 | 1300 |

1100 | 160-320 | Various scrap steel that not less than 6mm in thickness | 4-10 | 4800*2900*3200 | 16.6 | 1600 |

1600 | 400-900 | Large metal packages, car shells | 15-21 | 6500*4200*3800 | 36.3 | 2400 |

1800 | 460-1200 | Car shells, large scrap metal blocks, various scrap metals | 19-24 | 5000*5200*4100 | 48.2 | 2800 |

2000 | 530-1500 | Car shells, large scrap metal blocks, various scrap metals | 24-28 | 5000*7200*5500 | 75.8 | 3000 |

The interests of the customer is our first consideration, our service pursuit refinement, strong design, development, manufacturing, installation, debugging and technical maintenance, each link has made careful arrangements, to solve the customer a series of worries.

The company officially registered on 27th Feb. 1995and set up factories in Gongyi City, Henan Province , since then, our factory made from crushing, molding, drying, sorting, cleaning, recycling equipment and other mechanical equipment, accumulated experience day by day.

Q: How do I know the quality of your machine?

A: we can test the machine and we can send you vedio the machine how to work.Also welcome you to visit our factory to see our machine personally.

Q: Which brand of motor will you use?

A: Siemens brand motor, but you can choose other brand motor.

Q: How to install?

A: we can arrange engineer to install.Or customer arrange people to come to our factory to learn how to install.

Q: How long is the machine take?

A: It normally takes 10 days, and it takes 30 days to customize the machine

Q: How long is the warranty period of the equipment?

A: 1 year.

Metal shredder machine Wire/cable recycling machine Copper aluminum sorting machine

Scrap steel crushing line Garbage recycling line PCB recycling line

If you are interested in our products, you may contact us within 24 hours