Автоматический аппарат для дуговой сварки сборочный конвейер робот

- Категория: Other Welding Equipment >>>

- Поставщик: Zaoqiang,Dacheng,Rubber,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.51 $* | 0.11 $* |

| Aug-17-2025 | 0.6 $* | 0.22 $* |

| Jul-17-2025 | 0.76 $* | 0.72 $* |

| Jun-17-2025 | 0.78 $* | 0.49 $* |

| May-17-2025 | 0.47 $* | 0.77 $* |

| Apr-17-2025 | 0.3 $* | 0.48 $* |

| Mar-17-2025 | 0.23 $* | 0.79 $* |

| Feb-17-2025 | 0.61 $* | 0.9 $* |

| Jan-17-2025 | 0.93 $* | 0.40 $* |

Характеристики

Product Description

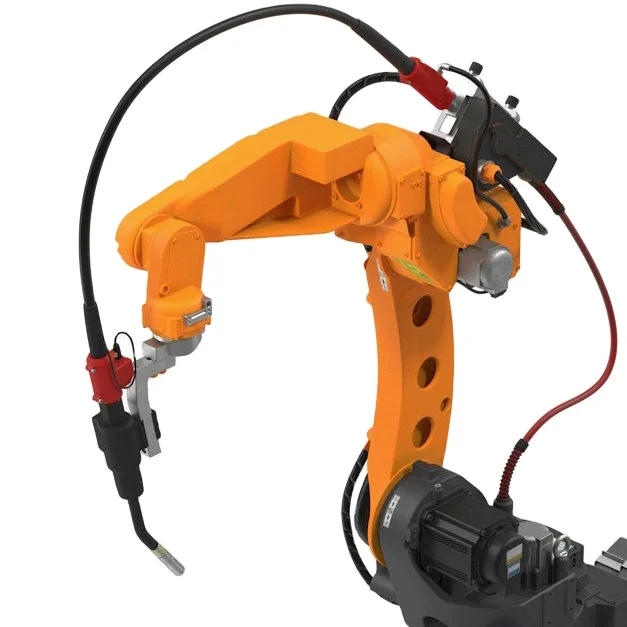

Structure | Vertically Articulated,6 degrees of Freedom | ||||||

Application | Welding | ||||||

Payload | 6KG | ||||||

Position Repeatability | ±0.08mm | ||||||

Power Capactity | 1.7KVA | 3.7KVA | |||||

Range of Motion P-Point | see blow | ||||||

Robot Weight | 170KG | 300KG | |||||

Range of Motion | Basic Axis | J1 | ±170° | ||||

J2 | +178° -65° | +0° +175° | |||||

J3 | +82° -68° | +90° -80° | |||||

Arm Axis | J4 | ±150° | ±170° | ||||

J5 | +22° -202° | +125° -90° | |||||

J6 | ±330°(Remarks 1) | ±220° | |||||

Maximum Speed | Basic Axis | J1 | 119°/S | 136°/S | |||

J2 | 136°/S | 135°/S | |||||

J3 | 137°/S | 125°/S | |||||

Arm Axis | J4 | 160°/S | 150°/S | ||||

J5 | 156°/S | 150°/S | |||||

J6 | 346°/S | 333°/S | |||||

Mounting Positions | Ground and Ceiling and Portal and Wall | ||||||

Ambient Temperature | 0-45°,20-80%RH (No condensation) | ||||||

Protection Class | Comparable to IP67 | ||||||

Welding Robot

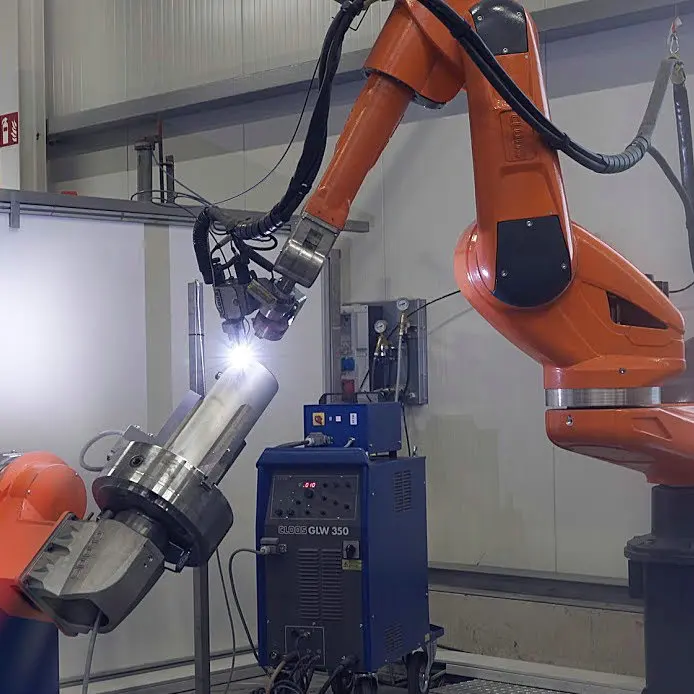

Arc Tracker, automatically adjusts the robot's vertical and lateral trajectory to compensate for part warping or misplacement. Often used with

Touch Sensing to find the start of the weld joint, through arc seam tracking measures feedback current and adjusts the robot's path to keep the weld in

the joint center. Through arc seam tracking can be used on many different joint configurations and material thicknesses. It is a reliable and cost

effective way to overcome part variations and produce high quality welds.

Touch Sensing to find the start of the weld joint, through arc seam tracking measures feedback current and adjusts the robot's path to keep the weld in

the joint center. Through arc seam tracking can be used on many different joint configurations and material thicknesses. It is a reliable and cost

effective way to overcome part variations and produce high quality welds.

Laser Seam Tracking

The laser sensor is attached to the robot arm approximately one inch ahead of the welding torch.It provides a three-dimensional real time method for tracking weld seams on material thickness less than 1 mm

or joints with less than 1 mm gap.

or joints with less than 1 mm gap.

Welding Pool

The vision system is capable of producing good images of TIG and MAG welding, successfully eliminating most of the arc

light from the image.

light from the image.

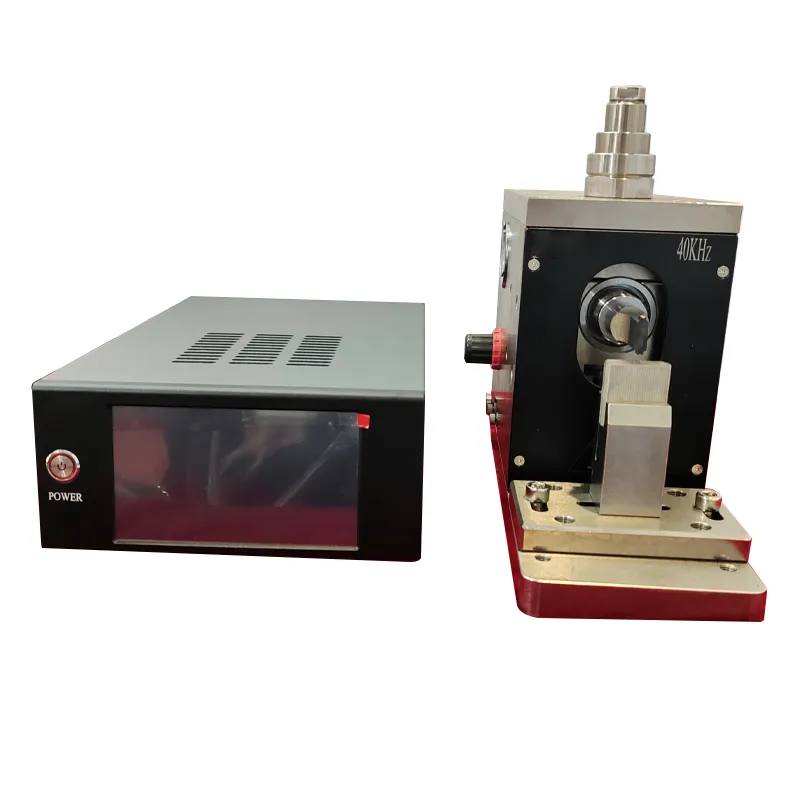

Industrial data acquisition platform

This platform can collect the current and voltage of welding power, welding gun Angle, protection gas flow, number of welding

layers, geographical position, environmental humidity, etc., for monitoring welding quality and industrial control traceability.

layers, geographical position, environmental humidity, etc., for monitoring welding quality and industrial control traceability.

Похожие товары

Недорогая паяльная машина для инфракрасного нагревателя IC T962A

US $300.00-$350.00

Стальной стержень арматурный сварочный аппарат

US $30000-$32000