Линия переработки отходов из Гренландии ПП ПЭ пластиковая пленка дробление

- Категория: Веревка для сушки >>>

- Поставщик: Zhangjiagang,Greenland,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 116620.74 $* | 122451.1 $* |

| Aug-16-2025 | 115640.24 $* | 121422.79 $* |

| Jul-16-2025 | 97020.47 $* | 101871.52 $* |

| Jun-16-2025 | 113680.13 $* | 119364.65 $* |

| May-16-2025 | 98980.22 $* | 103929.58 $* |

| Apr-16-2025 | 111720.17 $* | 117306.53 $* |

| Mar-16-2025 | 110740.34 $* | 116277.73 $* |

| Feb-16-2025 | 109760.27 $* | 115248.85 $* |

| Jan-16-2025 | 108780.90 $* | 114219.55 $* |

Характеристики

Product Description

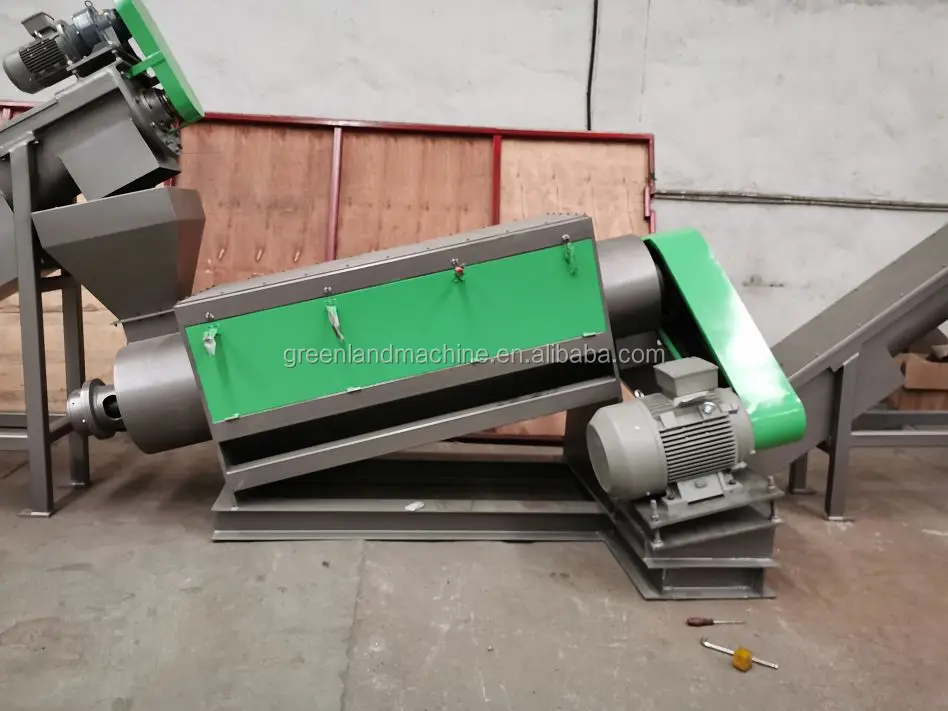

This Waste PP PE plastic film crushing washing recycling line is mainly used for waste HDPE/LDPE/PP film, bags, woven bag crushing, washing recycling.

The production line includes conveyor ,crushing (with water), rinsing, high-speed friction washing, dewatering, drying, collection and packaging systems;

The drying part can also be equipped with our latest film squeezing compactor machine or film squeezing dryer , which can greatly improve the dewatering rate, due to cancel the dewater and electric heating system, it can effectively reduce power consumption and improve customer economic benefits.

Production line scheme can be specially designed according to the pollution state of customer's raw material ,the quality requirements of the finished product.

The production line includes conveyor ,crushing (with water), rinsing, high-speed friction washing, dewatering, drying, collection and packaging systems;

The drying part can also be equipped with our latest film squeezing compactor machine or film squeezing dryer , which can greatly improve the dewatering rate, due to cancel the dewater and electric heating system, it can effectively reduce power consumption and improve customer economic benefits.

Production line scheme can be specially designed according to the pollution state of customer's raw material ,the quality requirements of the finished product.

Detailed Images

Flow chart:Shredding-Crushing-Washing-Drying-Pelletizing

Size Information

Technical parameter

Model | Capacity | Total power | Water supply | Labor | Area required |

GLW-300 | 300kg/h(films material) 500kgh (rigid pp/pe) | 130KW | 5-6 ton/h | 1~2 | 38*4.5*5m (L*W*H) |

GLW-500 | 500kg/h(films material) 1000kgh (rigid pp/pe) | 145KW | 6-8 ton/h | 1~2 | 38*4.5*5m (L*W*H) |

GLW-1000 | 1000kg/h(films material) 2000kgh (rigid pp/pe) | 190KW | 8-10 ton/h | 2~3 | 43*5*5m (L*W*H) |

Related Products

Packing&Shipping

Waste PP PE Plastic Film Crushing Washing Recycling Line

After Sales Service

Commissioning &training

Accept commissoining and inspection before delivery ,and offer installation help and technical support ,and instruction after

delivery

delivery

Company Introduction

ZHANGJIAGANG GREENLAND MACHINERY CO, LTD is a professional plastic recycling machine and extrusion machine manufacturer. We are dedicated to designing and developing the high technology plastic machinery. We have more than 10 years experiences in the plastic machinery manufacturing. We have full processing equipment,skillful and experienced production process . We are always keeping improve our products by the feedbacks and communication from our customers which makes our products better and better.

Our products mainly include PET bottle washing recycling line, PE/PP film bags washing recycling line, PP/PE bottle,drum washing recycling line, HDPE/ABS/ PVC recycling line, PE/PP recycling pelletizing line, PET ,ABS and etc material pelletizing line!

Plastic shredder series include single shaft shredder ,double shaft shredder ,plastic crusher/granulator.

At the same time, our company is also the leading EPS foam recycling machine manufacturer in China, manufacturing high quality EPS foam cold compression machine, hot melt machine, and EPS foam granulation equipment, fill the gap of domestic EPS foam high-end recycling equipment!

FAQ

TECHNICAL INNOVATION ,QUALITY FIRST

Greenland Machinery pays attention to technology research & development and product quality. Based on the company's mature R&D design team, we carry out technical reforms on traditional plastic recycling equipment. It insists on high-quality configuration for each component and detail of the equipment, compared with traditional recycling equipment ,more stable, high performance and efficiency, increase the economic benefits of recycling manufacturers!

OFFER DIFFERENT CUSTOMERS CUSTOMIZED SOLUTIONS OF PLASTIC RECYCLING

Greenland Machinery provides customized and integrated crushing washing and pelletizing solutions according to different recycling materials and capacity requirements of customers, which can help customers recycle various of materials and different pollution levels.Includ PET bottles, PP/PE Films/plastic bags/bottle, waste plastic packages agricultural film greenhouse film, jumpo bag, home appliance plastic, etc.

ONE-STOP TURNKEY PROJECT CONCEPT

Since the customer consider setting up recycling project, we will design the most suitable production line process and

installation plan according to the customer's capacity demand, workshop condition, etc. Our design and engineering team will provide customers with one-stop turnkey plastic recycling project.With complete pre-sale and after-sales service

INSTALLATION ,TRAINING & GOOD AFTER-SALES SERVICE

We have professional technicians who can come to customer's factory provide installation and commissioning, train operators, so that ensure the correct operation and maintenance of the equipment! We have dedicated after-sales personnel and spare parts warehouse to ensure the timely supply of some conventional accessories parts!

Greenland Machinery pays attention to technology research & development and product quality. Based on the company's mature R&D design team, we carry out technical reforms on traditional plastic recycling equipment. It insists on high-quality configuration for each component and detail of the equipment, compared with traditional recycling equipment ,more stable, high performance and efficiency, increase the economic benefits of recycling manufacturers!

OFFER DIFFERENT CUSTOMERS CUSTOMIZED SOLUTIONS OF PLASTIC RECYCLING

Greenland Machinery provides customized and integrated crushing washing and pelletizing solutions according to different recycling materials and capacity requirements of customers, which can help customers recycle various of materials and different pollution levels.Includ PET bottles, PP/PE Films/plastic bags/bottle, waste plastic packages agricultural film greenhouse film, jumpo bag, home appliance plastic, etc.

ONE-STOP TURNKEY PROJECT CONCEPT

Since the customer consider setting up recycling project, we will design the most suitable production line process and

installation plan according to the customer's capacity demand, workshop condition, etc. Our design and engineering team will provide customers with one-stop turnkey plastic recycling project.With complete pre-sale and after-sales service

INSTALLATION ,TRAINING & GOOD AFTER-SALES SERVICE

We have professional technicians who can come to customer's factory provide installation and commissioning, train operators, so that ensure the correct operation and maintenance of the equipment! We have dedicated after-sales personnel and spare parts warehouse to ensure the timely supply of some conventional accessories parts!