1000kghr линия по переработке ПЭТ хлопьев компании

- Категория: >>>

- Поставщик: Zhangjiagang,Jin,Machine,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.64 $* | 0.40 $* |

| Aug-15-2025 | 0.48 $* | 0.41 $* |

| Jul-15-2025 | 0.90 $* | 0.22 $* |

| Jun-15-2025 | 0.74 $* | 0.17 $* |

| May-15-2025 | 0.68 $* | 0.21 $* |

| Apr-15-2025 | 0.9 $* | 0.86 $* |

| Mar-15-2025 | 0.34 $* | 0.57 $* |

| Feb-15-2025 | 0.92 $* | 0.55 $* |

| Jan-15-2025 | 0.51 $* | 0.25 $* |

Характеристики

Product Overview

pet bottle flakes washing recycling production line plastic washer manufacture

PET Bottle Recycling Washing & Cleaning Production Line

>>Rigid Plastic(HDPE/PP/ABS/PC/PS/PET) Washing Line is one of the main recycling series of Jin machinery. This system has smart

modular design aiming at blow molding packaging bottle/box/cup/barrel/bucket and injection waste recycling.

>>Including sorting, size reduction, metal removing, cold and hot washing, high efficiency friction washing and drying modular.

Which can remove ferrous and nonferrous metals, sand, oil, glue, paper and many other different contaminants efficiency.

>>You can get a different module combinations design from KITECH according to your requirements and material's condition. In range

of different raw materials, KITECH provides 400-5000kg/h economy and high-level production lines with different configurations.

Recycling line

1. What can our machines do for you?

>>High automation, only 2 workers are required to operate

>>High production capacity (more than 30% higher than the same equipment in the same industry), low energy consumption (water,

electricity, gas, chemical cleaning agent consumption is 20% lower)

>>Reasonable process design and good cleaning effect

>>Reliable components, internationally renowned brands, reliable quality, low maintenance costs

>>Cost-effective, high profit return

2. Working processing:

>>After getting waste plastic raw material, KITECH Technicians will study and analysis the main contaminants to provide a proper

solution to remove most of the impurities by mechanical, chemical, physical and other principle.

>>Main process of whole project including pretreatment of raw material → crushing → washing → drying → package → granulation.

>>Rigid Plastic(HDPE/PP/ABS/PC/PS/PET) Washing Line is one of the main recycling series of Jin machinery. This system has smart

modular design aiming at blow molding packaging bottle/box/cup/barrel/bucket and injection waste recycling.

>>Including sorting, size reduction, metal removing, cold and hot washing, high efficiency friction washing and drying modular.

Which can remove ferrous and nonferrous metals, sand, oil, glue, paper and many other different contaminants efficiency.

>>You can get a different module combinations design from KITECH according to your requirements and material's condition. In range

of different raw materials, KITECH provides 400-5000kg/h economy and high-level production lines with different configurations.

Recycling line

1. What can our machines do for you?

>>High automation, only 2 workers are required to operate

>>High production capacity (more than 30% higher than the same equipment in the same industry), low energy consumption (water,

electricity, gas, chemical cleaning agent consumption is 20% lower)

>>Reasonable process design and good cleaning effect

>>Reliable components, internationally renowned brands, reliable quality, low maintenance costs

>>Cost-effective, high profit return

2. Working processing:

>>After getting waste plastic raw material, KITECH Technicians will study and analysis the main contaminants to provide a proper

solution to remove most of the impurities by mechanical, chemical, physical and other principle.

>>Main process of whole project including pretreatment of raw material → crushing → washing → drying → package → granulation.

FEATURES AT A GLANCE

High degree of off-standard

High level of automation

Can be remotely controlled

Low energy consumption

Low water consumption

High degree of dryness

High level of automation

Can be remotely controlled

Low energy consumption

Low water consumption

High degree of dryness

friction washer

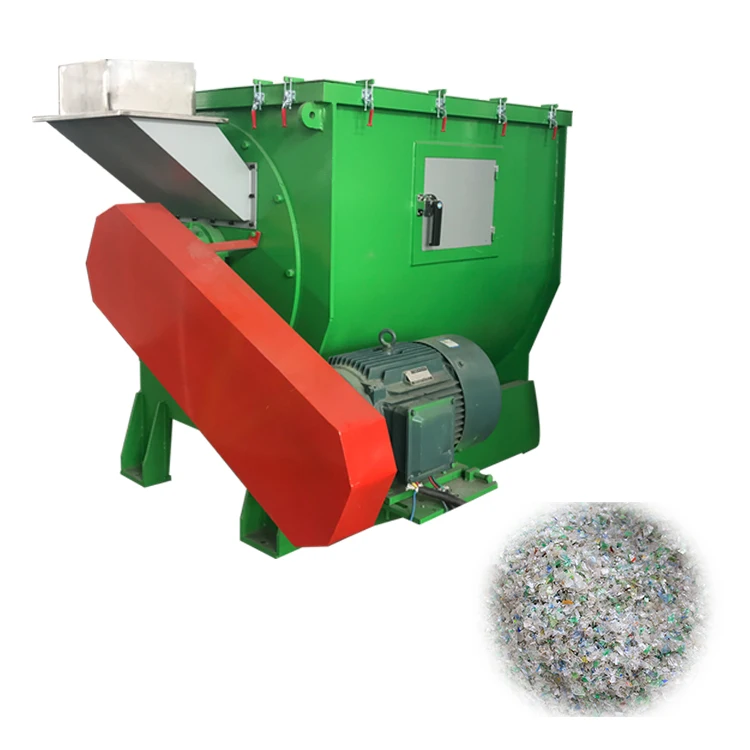

crusher

screw loader

PRODUCT SPECIFICATIONS

No | ITEM | NO | ITEM | |

1 | belt conveyor | 9 | screw loader | |

2 | lable remover | 10 | floating washer | |

3 | belt conveyor | 11 | vertical dewatering machine | |

4 | crusher | 12 | drying system | |

5 | screw loader | 13 | silo | |

6 | hot washer | 14 | electric cabinet | |

7 | screw loader | |||

8 | high speed friction washer |

PRODUCT CONFIGURATION

hot washer

friction washer

debaler

Usually, the process steps of the PET beverage bottle crushing and cleaning line are: 1, unpacking and sorting, 2, stripping, 3, crushing, 4, sink and float separation, 5, friction cleaning, 6, high temperature hot washing, 7, and friction cleaning again, 8, rinsing, 9 dehydration and bagging. These nine steps are the most commonly used processes in the PET bottle flake crushing, cleaning and recycling process. In fact, if you want to achieve greater output and better quality requirements, there are more complex processes, such as color sorting, fine breaking, and hot melt.

Unpacking and sorting

It is to dismantle the packed ton of bottle bricks, so as to pick out the impurities of the bottle bricks (such as bricks, wood, heterogeneous bottles, etc.

De-labeling

Crushing

Separation of ups and downs

The crushed bottle flakes sink into the bottom of the water tank through the PET material of the bottle body, and are finally lifted up by the elevator, while the PE bottle cap material floats on the water surface and the bottle cap material is removed by the salvage machine to realize the bottle cap and the bottle. Separation.

Friction cleaning

High temperature hot washing

By adding industrial alkali to hot washing in high temperature water, the grease on the surface of the PET bottle flakes can be removed, making it more clean and transparent.

floating washer

Dewatering and bagging

the water on the bottle flakes is removed by a high-speed dewatering machine, and finally bagging.

Our Services

1.Before order: We will provide relevant information on various technology and business consulted by customers. If clients want to visit our company, we will offer all they need for convenience.

2.During order: company designs groundsill installation chart for water, electricity and gas of equipment basing on real condition and customers’ requirements and provides detail order list and matching manufacturer for reference for customer. After equipment arrival, our service personnel will arrive at posted locale for installation, debugging, training and technology transfer till customers can operate independently and manufactures eligible product. Service personnel have to arrive at customer’s locale in time when we provide service for client again.

3. After order: we will offer 12months after sales service freely, but our service will be life-long. if some parts are broken, we will send them by express, air or ship as soon as we can.

Company Information

Jin Machine is an modern family-owned enterprise, which was established in 2006. Through 15 years of experience and technical

accumulation, now we become our province's new & high-technology company. Besides, we cooperate with the national famous

university insistution and founded the manufacturing base for production, study and researching.

Our main products include:

1. PET PP strap production line;

* Wasted plastic washing recycling granulating line;

* Efficient pre-crystallization and dehumidification drying system;

* Central feeding system for plastic materials;

* Auxuliary machine for plastic machine lines.

Our Factory Advantages:

* Manufacturing experience 15+years

* Quality control system application

* Industry-University-Research Integration

* Customerized Making Request Meeted

* Provide 24hours consultation

2.During order: company designs groundsill installation chart for water, electricity and gas of equipment basing on real condition and customers’ requirements and provides detail order list and matching manufacturer for reference for customer. After equipment arrival, our service personnel will arrive at posted locale for installation, debugging, training and technology transfer till customers can operate independently and manufactures eligible product. Service personnel have to arrive at customer’s locale in time when we provide service for client again.

3. After order: we will offer 12months after sales service freely, but our service will be life-long. if some parts are broken, we will send them by express, air or ship as soon as we can.

Company Information

Jin Machine is an modern family-owned enterprise, which was established in 2006. Through 15 years of experience and technical

accumulation, now we become our province's new & high-technology company. Besides, we cooperate with the national famous

university insistution and founded the manufacturing base for production, study and researching.

Our main products include:

1. PET PP strap production line;

* Wasted plastic washing recycling granulating line;

* Efficient pre-crystallization and dehumidification drying system;

* Central feeding system for plastic materials;

* Auxuliary machine for plastic machine lines.

Our Factory Advantages:

* Manufacturing experience 15+years

* Quality control system application

* Industry-University-Research Integration

* Customerized Making Request Meeted

* Provide 24hours consultation