Производство листового металла в Китае изготовление на заказ сделай сам усилитель корпус из

- Категория: Electronic & Instrument Enclosures >>>

- Поставщик: Foshan,Nanhai,Wongsam,Sheet,Metal,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 2.6 $* | 2.85 $* |

| Aug-20-2025 | 2.97 $* | 2.62 $* |

| Jul-20-2025 | 2.8 $* | 2.93 $* |

| Jun-20-2025 | 2.56 $* | 2.27 $* |

| May-20-2025 | 2.28 $* | 2.9 $* |

| Apr-20-2025 | 2.1 $* | 2.41 $* |

| Mar-20-2025 | 2.61 $* | 2.57 $* |

| Feb-20-2025 | 2.37 $* | 2.10 $* |

| Jan-20-2025 | 2.16 $* | 2.19 $* |

Характеристики

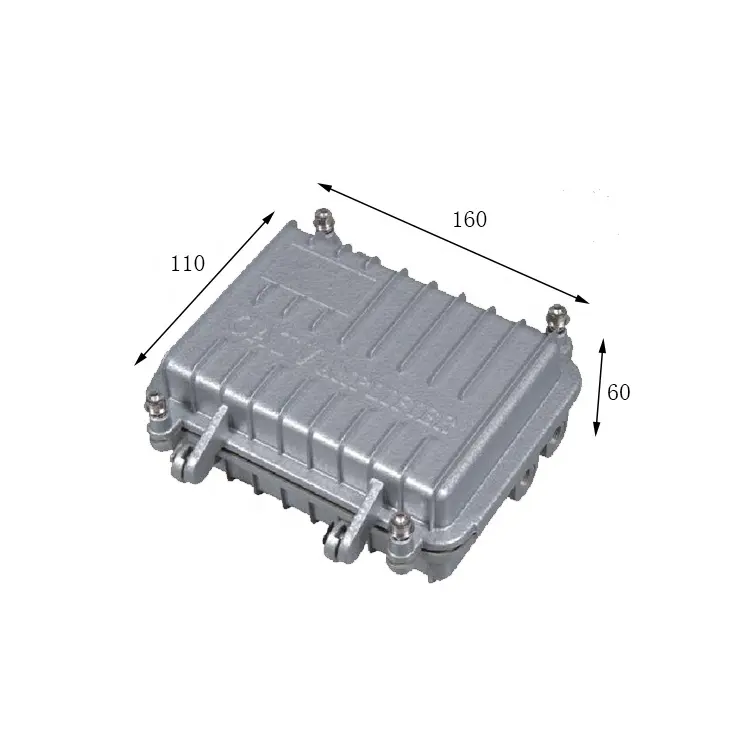

china sheet metal fabrication custom diy amplifier chassis aluminum

| Product Description |

| Material | Carbon steel, Mild steel,Cold roll steel,Hot roll steel,Zinc plate,Stainless steel, Aluminum, iron,brass,Titanium,SECC, SGCC, SPCC, SPHC, Other metal |

| Thickness | 0.8mm~ 16.0mm ,Depends on your products |

| Specification | Customized According to your drawing |

| Surface finish | Zinc plating, Electroplating , Nickel plating, Anodic oxidation, Chrome plating, Yellow zinc plated, Electroless nickel plating, Chemical conversion coating, Powder Coating, Liquid painting Galvanized,Brushed, Sand blasting, Passivation , Heat treatment Silkscreen Custom as your special requirement |

| Manufacturing Service | Laser cutting / Shearing / Punching / Bending / Welding / Coating / Others |

| Application | Metering Box,Termination Box,Aluminum Enclosure,Server Rack,Electric Enclosure,Amplifier Chassis,Distribution Box,Network Cabinet,Lock Box,Control Box,Junction Box,Electrical Boxes |

| Drawing File | 2D: DWG,DXF, PDF 3D: ASM,DRW,DWG,DXF,IGS,STEP,so on |

| Product details |

Products Category |

| Our Service |

“Design for Manufacturing”

As a Customized Sheet Metal Design Fabrication ,we provide not only manufacturing service,but also sheet metal design Consulting Service.

Through consulting, we can find out where to cost down but still keep product's quality.

We promise to you that your design can be manufactured just according to your budget and quality request.

| Our Advantage |

1.Small details make big difference. We promise:All the parts from our company have no sharp edge. All dimensions are controlled according to your drawings. Every product will be fully inspected and carefully packed to prevent the bump and rust in transit .

2. The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart.

3. Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and professional inspectors.

4. Each size of product must be tested one by one after completing production and provide quality report.

5. The most important point, we are the entity factory, not trading company. Price is the composition of the actual product quality price. Quality can guarantee more controllable higher than trading company. The price is competitive, at least reducing the trade company's service fee.

6.We have many years of export experience,exports to the US,Europe, Japan and other countries and regions.

7.Our team are more professional. We have more reasonable price and better quality controlling than trade company. And our language ability is also diversified.

| Production Process |

| Company Information |

| FAQ |

How to place your order :

1.Please send us your drawings( 2D&3D) or sample.

2.Our engineering team work on them and submit competitive quotation for you.

3.Confirm sample order and fabricate samples after you approve the quotation and submit them to you for your inspection.

4.Confirm production order after you approve samples.

5.Payment and shipping terms are negotiable.

Q1: How to have my components quoted ?

A1: Please contact us via TradeManager or Email and send us your drawings inclusive of 2D and 3D( .STEP or .IGES files) and detail requirements. We are pleased to sign NDA with you if you prefer. Then our engineering team will work on them and submit competitive quotation to you.

Q2: What is the lead time for tooling and samples fabrication?

A2: The exact lead time depends on your parts specification.

The normal lead time is 40-45 days for tooling fabrication and samples.

If the tooling is not required, the lead time for samples is 15 days normally.

Q3: Can I have prototypes for testing before tooling ?

A3: Yes, our factory have team to support prototypes with machining process to fabricate them for your testing.

Q4: How to ship the samples and production order ?

A4: We will normally ship samples via DHL, UPS or FedEX via our cooperated forwarder or freight collect. For the shipping of production order, it will be by sea or by air.

Q5: How to ensure the quality of parts?

A5: Firstly, our team will inspect all incoming material. QC team will inspect parts while production and finished products, then submit Quality Inspection Report together with samples and production order.