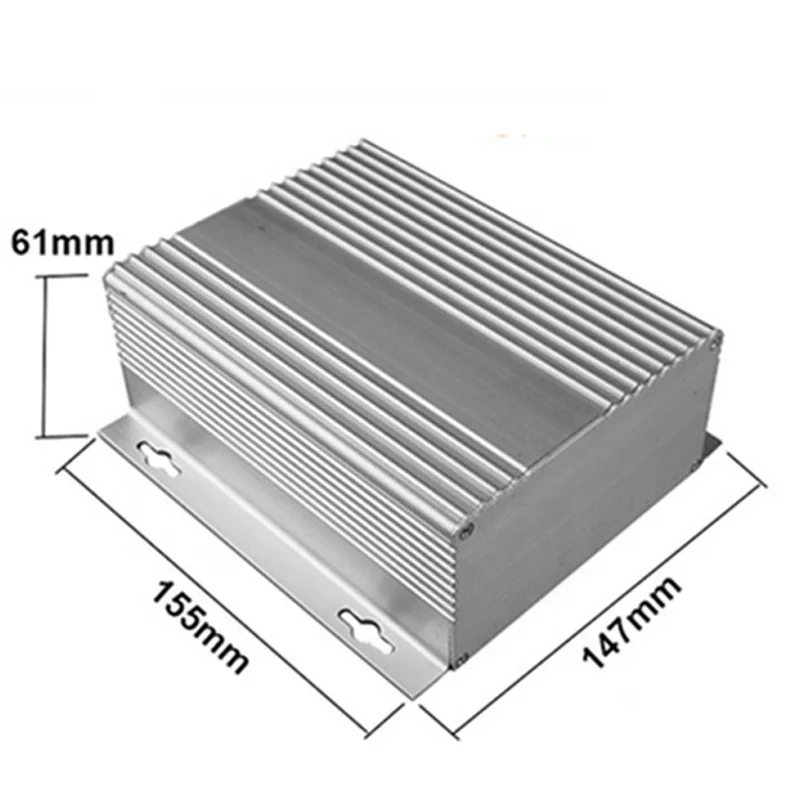

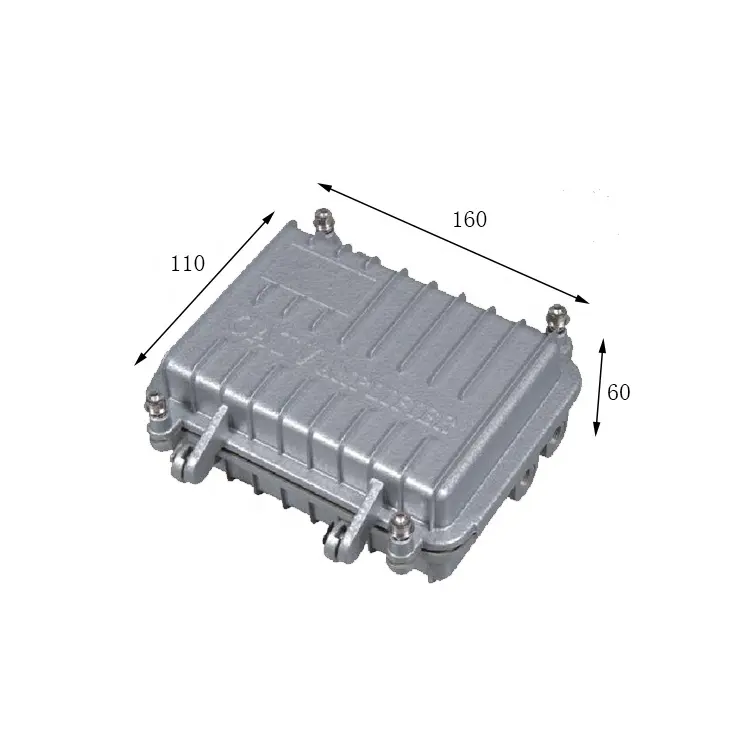

Высококачественный красивый внешний вид распылитель экструзия анодированный Тяговый провод корпус из алюминиевого сплава для корпуса аудиовизуального

- Категория: Electronics & Instrument Enclosures >>>

- Поставщик: Shenzhen,Tontinco,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.69 $* | 0.37 $* |

| Aug-15-2025 | 0.55 $* | 0.72 $* |

| Jul-15-2025 | 0.48 $* | 0.11 $* |

| Jun-15-2025 | 0.90 $* | 0.18 $* |

| May-15-2025 | 0.0 $* | 0.80 $* |

| Apr-15-2025 | 0.26 $* | 0.93 $* |

| Mar-15-2025 | 0.88 $* | 0.53 $* |

| Feb-15-2025 | 0.37 $* | 0.11 $* |

| Jan-15-2025 | 0.77 $* | 0.34 $* |

Характеристики

For Free Sample or Know More Details, Contact Us !!!

What we can do:

1. Provide :Focus on OEM & ODM;

2. Provide :Free Sample Offered;

3. Provide :FAST DELIVERY;

4. Provide :Strict Quality Control Process;

5. Provide :ISO 、IATF、SGS certified;

6. Provide :24-HOUR ONLINE,Professional efficient communication;

7. Provide :A professional engineering team with rich experience;

8. Provide :29 + years Professional ONE-STOP CNC Machining Parts Factory&Manufacturer;Focus On Various CNC Precision Machining;

9. Provide :CNC Machined Parts,Turning Parts,Milling Parts,Turn-mill Combination Parts,Metal Sheet Parts,CNC Brass Parts,CNC

Aluminum Parts,CNC Steel Parts,Die Casting,Medical instrument parts,Plastic Parts,cnc turning parts,cnc machining parts,sheet metal parts etc.

1. Provide :Focus on OEM & ODM;

2. Provide :Free Sample Offered;

3. Provide :FAST DELIVERY;

4. Provide :Strict Quality Control Process;

5. Provide :ISO 、IATF、SGS certified;

6. Provide :24-HOUR ONLINE,Professional efficient communication;

7. Provide :A professional engineering team with rich experience;

8. Provide :29 + years Professional ONE-STOP CNC Machining Parts Factory&Manufacturer;Focus On Various CNC Precision Machining;

9. Provide :CNC Machined Parts,Turning Parts,Milling Parts,Turn-mill Combination Parts,Metal Sheet Parts,CNC Brass Parts,CNC

Aluminum Parts,CNC Steel Parts,Die Casting,Medical instrument parts,Plastic Parts,cnc turning parts,cnc machining parts,sheet metal parts etc.

Advantage | One-Stop Solution for Mechanical Customers Rich experience in Small Volume & Large variety Rich experience in Large Volume 29 Years field experience, and 80+ engineers |

Processing Method | CNC machining. Turning. Milling, Stamping, Sheet metal. Screw manufacturing, Assembly |

Materials Available | Stainless steel Carbon steel, Brass, Bronze. Iron, Alumunum alloy, Nylon, SPCC, SECC, etc. |

Materials Standard | GB. ASTM, EN, DIN, JIS, BS, ANSI. SAE |

Processing Capacity | Outer diameter: 0.5mm-500mm Length: 1.0mm-2000mm |

Tolerance | ± 0.002mm |

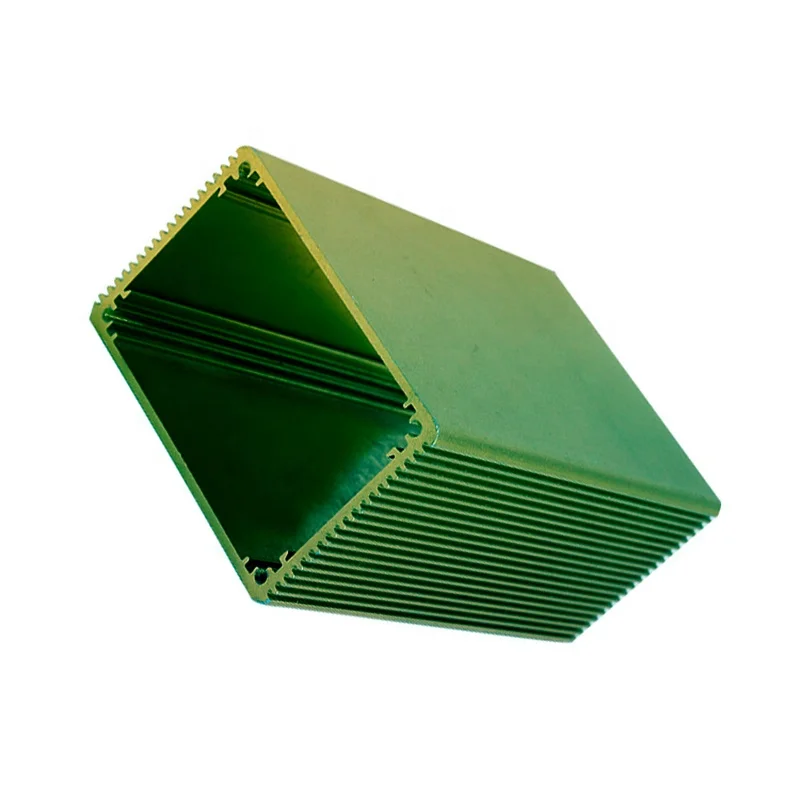

Surface Treatment | Anodizing, Sandblast, Electroplating. Powder coating. Liquid Painting, PVD, Electrolytic polishing, ect. |

Equipment | Over 70 sets automatic lathes, over 30 sets CNC lathes, over 10 sets CNC machining center, over 200 sets secondary processing machines. |

RFQ | Customer Inquiry → Engineering Communication → Cost Analysis →Sales Analysis →Quote to Customer » 1-3 Work Days Only » Submit RFQ with complete commercial terms |

Sample Making | Sample Order → Engineering Review → Sample Plan to Customer → Sample Status Tracking → Submit Samples with Doc. » Tooling L/T: 2-4 wks. Sample L/T: 2 wks » Continuous Sample Status Tracking » Complete Documents for sample approval |

Order Management | CRM System → Open Order Confirm → Logistic Arrangement. » Production L/T: 2-4 wks » Weekly Open Order Confirm » Preferred 3PL Service to Customers |

Quality Control | Certificates: RoHS, 1809001:2015, SGS. IQC → IPQC → OQC/FQC → Quality Complain Feedback → Audit & Training. » Plant Audit and Qualified by world famous company » Strict Quality Management Procedure with Traceability |

Application | Aerospace/ Marine/ Metro/ Motorbike/ Automotive industries. Instruments & Meters. Office equipments, Home appliance. Medical equipments, Telecommunication, Electrical & Electronics, Fire detection system, etc. |

Stamping Machining

Stamping process is a metal processing method, which is based on the plastic deformation of metal. It uses molds and stamping

equipment to apply pressure to the sheet, so that the sheet is plastically deformed or separated, so as to obtain a certain shape,

size and performance parts (stampings).

equipment to apply pressure to the sheet, so that the sheet is plastically deformed or separated, so as to obtain a certain shape,

size and performance parts (stampings).

CMM

There are many features measured by the CMM, and almost all types of dimensional measurements can be measured by the CMM. Through

the structural features, it is possible to detect flatness, roundness, concentricity, etc.

the structural features, it is possible to detect flatness, roundness, concentricity, etc.

Company Introduction

Company profile:

Shenzhen Tontinco Industrial Co., Ltd., founded in 1993, has two professional hardware manufacturers and four different metal processing production lines, mainly producing welding, screw manufacturing, sheet metal manufacturing, CNC numerical control processing services.

The old factory is located in Dongguan, Guangdong, and the new factory is located in Shenzhen, China.

The old factory is located in Dongguan, Guangdong, and the new factory is located in Shenzhen, China.

Committed to providing customers with one-stop service of metal processing

We specialize in manufacturing high-quality mechanical parts of various materials and carry out a series of surface treatments。

To meet the needs of different applications. For example, our parts are used in automotive, aerospace, agriculture, medical, commercial machinery, industry, 3D printing and many other structural fields.

Unlike other machining companies, we focus on quality control and delivery time efficiency. More importantly, in order to achieve incredible size, we imported most of the machines from the Japanese brand tsugaml. The minimum tolerance can reach 0.002mm

We specialize in manufacturing high-quality mechanical parts of various materials and carry out a series of surface treatments。

To meet the needs of different applications. For example, our parts are used in automotive, aerospace, agriculture, medical, commercial machinery, industry, 3D printing and many other structural fields.

Unlike other machining companies, we focus on quality control and delivery time efficiency. More importantly, in order to achieve incredible size, we imported most of the machines from the Japanese brand tsugaml. The minimum tolerance can reach 0.002mm

Address of our old factory:

Building C, Hongji high tech Zone, Yantian village, Fenggang town, Dongguan City, Guangdong Province

Address of the new plant:

Address of the new plant:

No.1 plant, No.5 Tianhua street, Pinghu Town, Shenzhen

Welcome to the factory for visit and guidance

Customer Feedback

Qualification

Customer Communication

Packaging & Shipping

FAQ

Q1: How long can i get the sample?

3-5 days,10-15 days for bulk orders.Depends on your specific items,We can expedite for you.

Q2:How to control product quality?

First full size inspection—Mass production—Check process (3 hours sampling)—100% Shipping random checks. We have professional QC team, control the quality during the mass production and inspect the completely goods before shipping.

Q3: What's kinds of information you need for quote?

Kindly please provide the product drawing in PDF, and will be better you can provide in DWG or STEP.

Q4: OEM/ODM, or customer’s logo printed is available?

YES,OEM/ODM, customer’s logo is welcomed.

Q5: What’s your payment terms?

Q5: What’s your payment terms?

Regularly doing 30%-50% deposit and 50%-70% balance by T/T, Western Union, Paypal, other payment terms also can be discussed based on our cooperation.

Q6: If we don’t have shipping forwarder in China, would you do this for us?

We can offer you best shipping line to ensure you can get the goods timely at best price.

We can offer you best shipping line to ensure you can get the goods timely at best price.

Q7: I never come to China before, can you be my guide in China?

We are happy to provide you one-stop service, such as booking ticket, pick up at the airport, booking hotel, accompany visiting market or factory.

Q8: What products can you do?

We can carry out CNC milling and turning, metal stamping, sheet metal, tooling, extrusion, die casting, forging, sintering, gear processing, gearbox assembly and fishing, and the processing and manufacturing of various screws. More one-stop solutions are available upon request.

Похожие товары

145*90*41 мм PLC011 пластиковый корпус din-рейки

US $1.00-$2.00

Ip67 DE211 большой пластиковый шарнирный ящик/корпус с окном

US $9.00-$10.00

Водонепроницаемый корпус с уровнем защиты Ip65

US $1.40-$1.90