3CBM HF лечения древесины дерева приправа

- Категория: Other Woodworking Machinery >>>

- Поставщик: Shijiazhuang,Saga,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 35700.22 $* | 37485.81 $* |

| Aug-16-2025 | 35400.28 $* | 37170.23 $* |

| Jul-16-2025 | 29700.97 $* | 31185.57 $* |

| Jun-16-2025 | 34800.40 $* | 36540.34 $* |

| May-16-2025 | 30300.70 $* | 31815.19 $* |

| Apr-16-2025 | 34200.38 $* | 35910.58 $* |

| Mar-16-2025 | 33900.26 $* | 35595.37 $* |

| Feb-16-2025 | 33600.33 $* | 35280.68 $* |

| Jan-16-2025 | 33300.22 $* | 34965.69 $* |

Характеристики

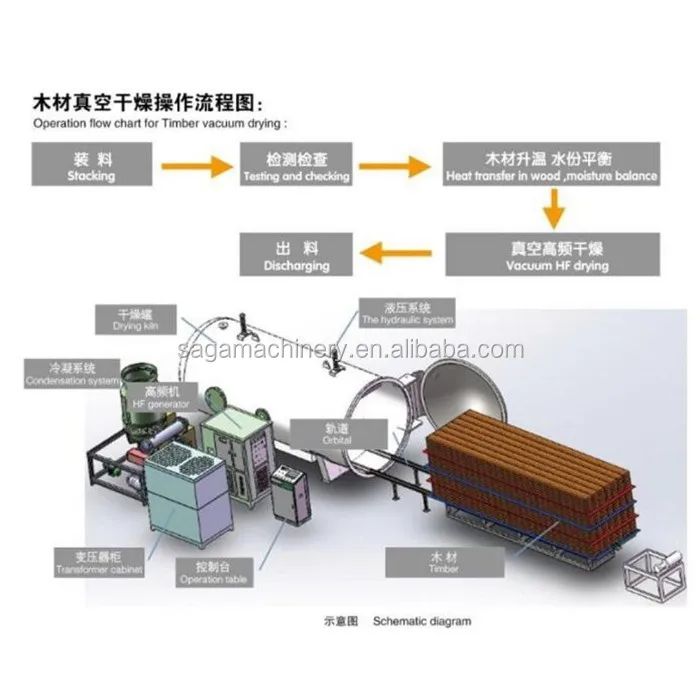

Feature of HF Timber Treatment Wood Seasoning Plant

*Fast drying cycle: heating by high frequency dielectric power,many times faster than conventional wood kilns

*Automatic feeder: feeding cart with a motor,easy to push the timber into the dryer

*Optional capacity: 3m3, 4.5m3, 6m3, 8m3, 10m3, 13m3, small but with a quick,automated drying cycle, meet different customer's requirement

*PLC automated systems with touch screen panel: easy to set data and operate,only One-button start and stop

*Uniform heating: HF power acts on water or moisture in the wood, make sure moisture uniform after drying

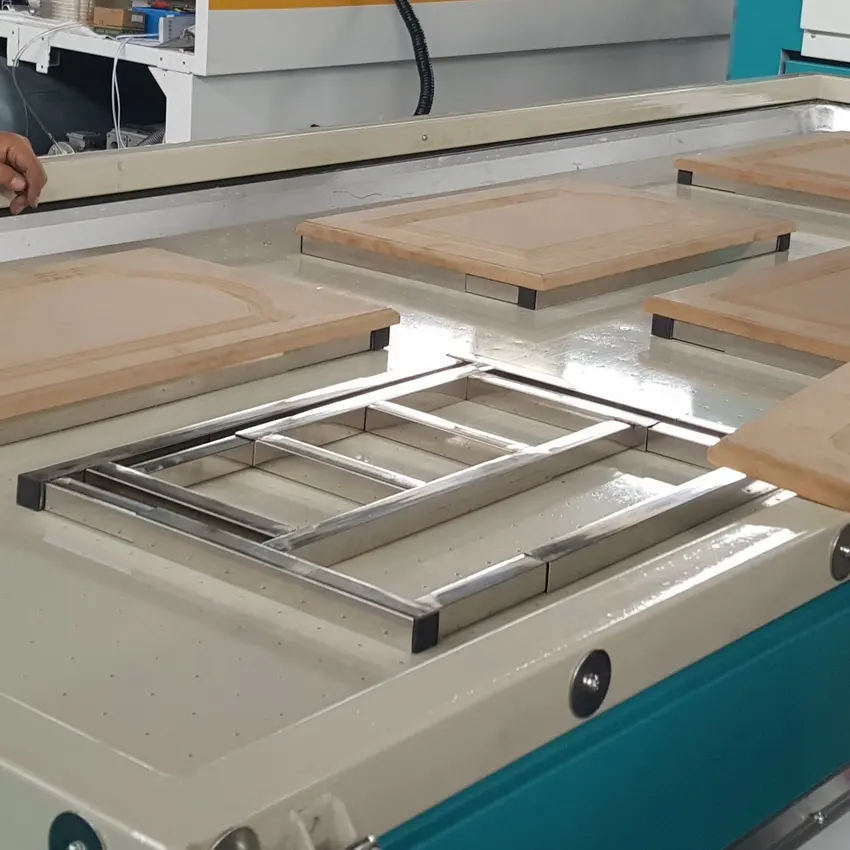

*No sparking or bending problem: hydraulic press cart keeps the wood straight

*Veneer, panels, softwood and hardwood planks, heavy timber with large dimension: suiatble for all kinds of wood

*Patented weighing system: calculate the moisture by program automatically, and showing recent moisture on PLC screen all the time

*Stainless steel cooling system: stainless steel vacuum pump, pipe and condenser,avoid of rusting problem

*Schneider, Omron, Siemens etc European spare parts: International standard, good quality and easy to replace

Our engineers can provide overseas installtion, training and are available to provide after-sell service and maintenance. We recommend proper training for sfe and prolonged use of the machinery.

Basic Parameter of HFVD30-SA

| Overall Size | High frequency generator | 950*1050*1950mm |

| Tank | 4300*2160*2100mm | |

| Cooling system | 1500*1150*2000mm | |

| Gross Weight | 5 Ton | |

| Tank | Inside diameter | 1700mm |

| Stacking timber size | 1000*1000*3000mm (3.28feet *3.28 feet * 9.84 feet) | |

| Stacking timber capacity | 3 cubic meters | |

| HF Generator | Input power | 40 Kva |

| Output power | 30 KW | |

| Temperature Testing | Fiber optical temperature sensor | |

| Moisture Testing | Weighing system (PATENT) | |

| Cooling System | Stainless steel condenser with stainless steel water-ring vacuum pump | |

| Dewatering | Full automatic type | |

| Hydraulic Cyliners | 3 ton (2 pieces of stainless steel cylinders) | |

| Vacuum Pump | Material | Stainless steel |

| Power | 7.5 Kw | |

| Feeder Type | Automatic Feeder | |

| Tank Door | Ears Door (more safe and powerful) | |

| Weighing System | Weighing sensors under then tank (weighting wood everytime) | |

| Control System | Full-auto PLC touch screen | |

| Packing | 20" GP (5 packages) | |

Optional Models

| Model | HF Input Power | HF Output Power | Stacking Timber Size | Stacking Timber Capacity | Container |

| HFVD45-SA | 40 kva | 30 kw | 1*1*4.5 m | 4.5 m3 | 40" |

| HFVD60-SA | 70 kva | 50 kw | 1*1*6 m | 6 m3 | 40" |

| HFVD80-SA | 70 kva | 50 kw | 1*1*8 m | 8 m3 | 40" |

| HFVD100-SA | 70 kva | 50 kw | 1.3*1.3*6 m | 10 m3 | 40" |

| HFVD120-SA | 70 kva | 50 kw | 1.3*1.3*8 m | 13 m3 | 40" |

Main Parts

1.High frequency generator

2.Control cabinet

3.Vacuum tank

4.Hydraulic system

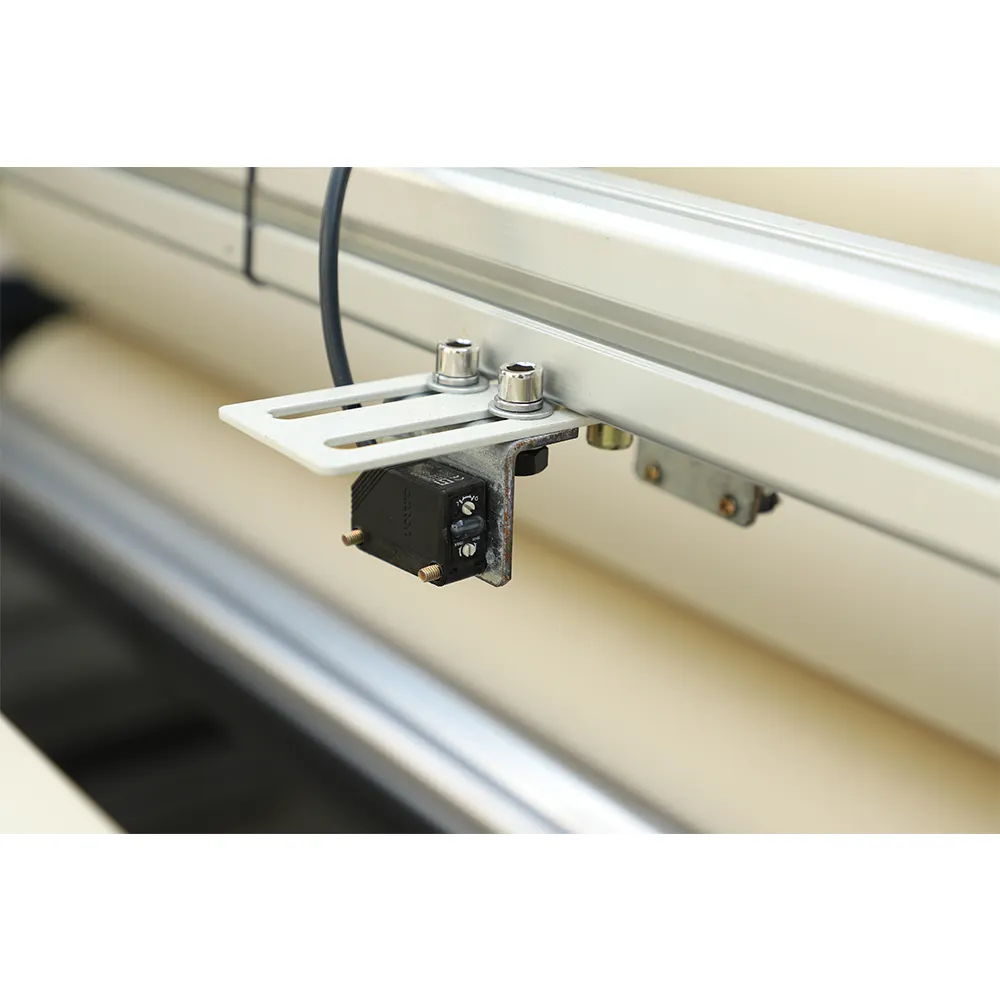

5.Weighing system

6.Temperature tesing system

7.Cooling system

8.Full-auto feeder

Drying Cases

| Case | Drying Time | Drying Result | Consumption |

| Sliced veneer | about 40 hours | High quality on flatness and water content uniform | 200~250kw/cbm |

| Surface of floorboard | about 45 hours | High quality on flatness, no end cracking and deformation, no color change | about 200kw/cbm |

| Middle hardwood for second time drying | about 35 hours | Relieving tension, make water content uniform and make wood stable | about 150kw/cbm |

| Hardwood drying | Rosewood: 7 days Red Sandalwood: 14 days | No cracking or deformation, moisture content uniform, more stable | about 500~600kw/cbm,different consumption for different wood |

| Large plank | 7~10 days , moisture content from 60% to 20%,10cm thick+, like Birch,Larch,Pinus and Pine | No deformation on vertical direction, no cracking problem, more stable | different wood with different power consumption |

Doing research in Wood Engineered Department of Chilean University

Pre-sale sevice:

1.Reply customer's email or call customer back if missed any calls.

2.Design the best processes and programs according to customer's requirement.

3.Answer customer's questions patiently

On purchase service

1.Commissioning the machines before shipment carefully.

2.Train the customer's technician, and provice operation video and matters needing attetion.

3.Arrange customs declaration, sea shipping, insurance,etc.

After-sale service

1.The warranty is 12 months, will provice spare parts for free this period,if customer break it in using, customers should take charge of delivery cost.

2.Provide the solution of installation or use problem within 3 working hours.

3.Engineers able to install and train the operators overseas.

Customer Feedback

Saga Machinery Co., Ltd is professional high frequency woodworking machinery manufacturer in China,our product cover with high frequency vacuum wood dryer, high frequency curved plywood press, high frequency edge gluing press, high frequency wooden door frame assembly machine, high frequency wood frame assembler, high frequency generator, etc. European standard spare parts are used to keep the machine stable and uniform.

We have customers in USA,Canada,Romania,Denmark,Holland,Turkey,Belarus,Russia,Ukraine,Vietnam,India,Korea,Indonesia,Philippines,Panama,Chile,Mozambique,Iran,Israel,Croatia,etc.

Saga can provide best quaility and after-sale service, will meet customer's requirement to make the production better and better, we are not only machine factory, but also project supplier, will recommend the suitable machine and project to customer.