Китайский поставщик пивных дрожжей паровой скребок барабанная сушилка машина для

- Категория: Vacuum Drying Equipment >>>

- Поставщик: Liaoyang,Wanda,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 23800.99 $* | 24990.98 $* |

| Aug-17-2025 | 23600.43 $* | 24780.87 $* |

| Jul-17-2025 | 19800.50 $* | 20790.42 $* |

| Jun-17-2025 | 23200.99 $* | 24360.17 $* |

| May-17-2025 | 20200.62 $* | 21210.9 $* |

| Apr-17-2025 | 22800.10 $* | 23940.55 $* |

| Mar-17-2025 | 22600.9 $* | 23730.54 $* |

| Feb-17-2025 | 22400.46 $* | 23520.22 $* |

| Jan-17-2025 | 22200.3 $* | 23310.13 $* |

Характеристики

Application

It is suitable for drying liquid raw material or sticky material in chemical industry, dyestuff industry, pharmaceutical industry, foodstuff industry, and metallurgy industry and so on.

Description

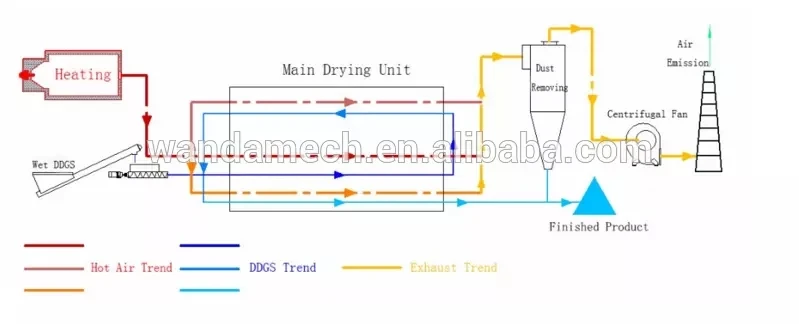

HG rotatary scraper roller drying machine is a kind of rotating continuous drying equipment with internal heating conducting-style. Certain thickness of materials film attach to the drum from material liquid vessel under the drum. Heat is transferred to the internal wall of the cylinder through pipes and then to the external wall and to materials film, to evaporate the moisture in materials film so as to dry materials. Dried products are then scraped off by the blade fitted on the surface of the cylinder, fall down to the spiral conveyor under the paddle, and are conveyed, collected and packed.

Features

1. High thermal efficiency. The principle of heat transfer of rotary dryer is heat conduction which heat conducting direction keeps identical with operation cycle. Except cap heat dissipation and radiation loss, all heat energy can be used for evaporating wet materials on the wall of roller. Thermal efficiency could reach 80%-90%.

2. Large operation elasticity and wide application. Various drying factors of the rotary drier can be adjusted, such as density of feeding materials, thickness of materials film, temperature of heating medium, rotating speed of roller etc, which can change drying speed. As these factors have no interrelations with each other, it brings great convenient to dry operation, and makes it applicable to suit various materials and to meet different requirement of production.

3. Short drying period. The drying period of material is normally 10 to 15 seconds, so it is suitable for heat-sensitive material. It can be also working under less pressure condition if it is put in vacuum device.

4. Drying rate is very quick. As material film coated on the wall of roller is very thin. Normally thickness is 0.3-1.5 mm, plus heat and mass transfer direction are identical, the evaporation capacity on the surface of film can keep at 15-70kg.H2O/m2.h.

Drawing:

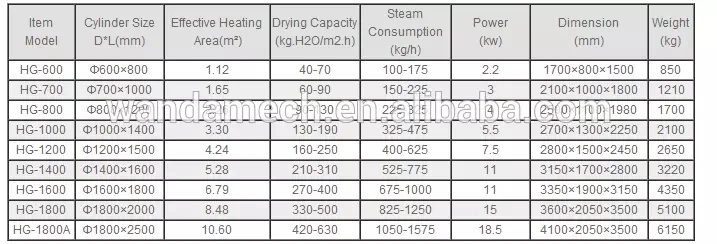

Product technical parameter:

|

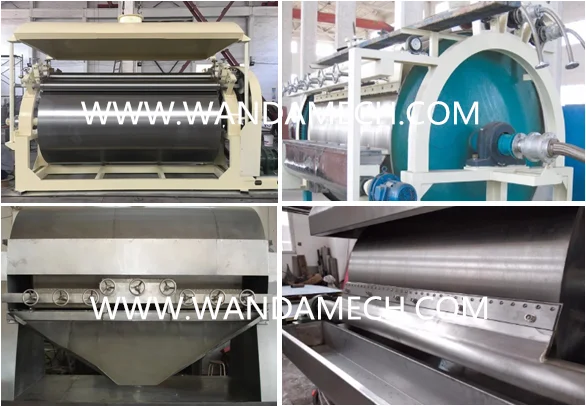

Product picture:

We sincerely invite you to be our long term relationship friend , and we always prepared to rovide our best services for you and would like you to know below we want to present :

l 1. Each machine is manufactured by professional experienced staff.

l 2. 12 months warranty + 100% QC inspection Before Shipment.

l 3. Overseas services provided. Technicians can be sent to spot for guiding the installation and debugging. Training operators and accomplish the commissioning.

l 4. Consultant services for whole machine life, 24 hours technical support by email and phone.When warranty date expired, lifetime maintenance service is provided and at buyer’s cost.

Company Information

Wanda Machinery Co., Ltd. specializes in R&D, manufacturing, operation, export and related services of drying oven, rotary flash dryers, centrifugal spray drying equipment, vibrating fluidized bed dryers, etc. Equipment designed over the years has been involved in the fields of medicine, chemicals, pesticides, electronics, mining, food, dyes, pigments and so on.

Our Team is full of experienced and qualified professionals, who have sound knowledge about the quality of our medical machinery. Our products are far sold to Europe, U.S.A., and many place around the world.

Other feature products: