WC67K 40T мини-пресс с ЧПУ для гибки и складывания стального

- Категория: Станочное оборудование >>>

- Поставщик: Anhui,Runbang,Heavy,Industry,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-17-2025 | 352099.49 $* | 359141.6 $* |

| Jul-17-2025 | 285560.48 $* | 291271.21 $* |

| Jun-17-2025 | 346554.95 $* | 353485.78 $* |

| May-17-2025 | 343781.22 $* | 350657.40 $* |

| Apr-17-2025 | 274471.19 $* | 279960.52 $* |

| Mar-17-2025 | 338236.18 $* | 345001.72 $* |

| Feb-17-2025 | 335464.60 $* | 342173.56 $* |

| Jan-17-2025 | 332692.68 $* | 339346.36 $* |

Характеристики

Main features:

WC67K CNC bending machine

1. E21 CNC system

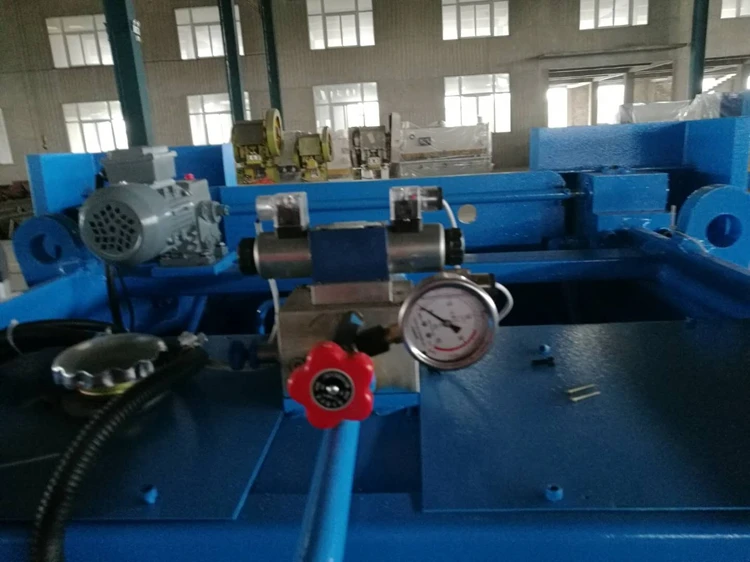

2.Germany Rexroth has the electro-hydraulic servo driven pump control system

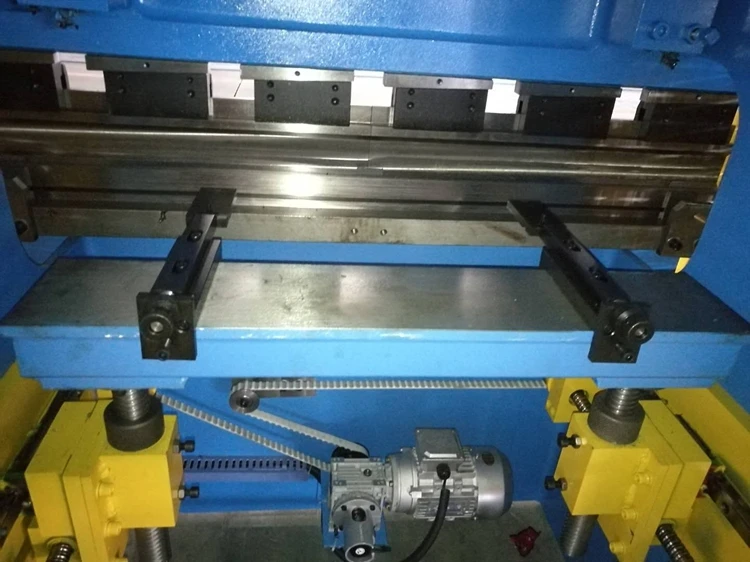

3.Synchronous position on both sides with RSF grating detection •Back gauge with high performance servo motor and ball screw •The WILA mechanical CNC system control under the table the deflection compensation device

4.With a left and a right protective door and rear fender •include standard front support with mobile linear guide track

Innovative features of the hybrid drive system:

1.Pump control techrology to replace conventional VRLA technology, eliminating throttling losses, no overflow losses, significant energy saving

2.Servo motor in a short time can significantly overload, the actual installed power is only 50% of the theoretical power installation

3.Tank volume decreases by 75% to reduce the usage amount of hydraulic oil

4.Low thermal equilibrium temperature without cooling devices, hydraulic components kfe extension

5.Free, fast, the packing, the r>ex( state return decreased noise, improve the worrvg environment

6.Servo motor brake faster than ihe average, an emergency pressure, flow rate cut soon

7.Reduce oil particles from sensitive NS7 grade level dropped NS9

Schneider brand electric components

quenching 42CrMo material

Manual back gauge finger

linear guide rail for manual adjusting

Siemens motor

for hydraulic system

Germany Rexroth Valve

Pressure control with high precision

Ensure no oil leakage

Lead time

30 ton to 200 ton press brake 15 days

250 ton to 1000 ton 20 to 40 days

Payment Method

30% T/T in advance, the balance paid before shipping

irrevocable L/C at sight

Anhui Runbang Heavy Industry Machinery Co., Ltd.

MTCNC concentrates on the research, development, manufacture, sale and service in metal fabrication equipment.

MTCNC not only supplies metal sheet shearing, bending, punching, rolling machine tool. but also provides you complete metal fabrication solution.

Manufacturing Part

gantry milling machine

gantry drilling machine

gantry boring machine

Material Stock Part

How is the lead time?

2 .For standard machine model, we can send machines out within 7 working days;

3. Customized type usually takes around 1 month to do.

How about your after-sale service?

2.Online video: show you machine working video in factory . ( update every month)

3.Installation service: this is available with all of our machines, We dispatch technician to customer's factory for installation machines. (Customers only need to pay for the airfare and hotel expense.)

4.Training service: Our technician will teach you how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

5.Quality guarantee: 1 year warranty, we provide lifetime service. We arrange final test before shipment, After making sure machine is the best performance, then make shipments.

6. 100% response rate: we will reply your questions within 12 hours.

Похожие товары

Новый ручной токарный станок с параллельной зубчатой головкой

ABM1300 акриловая машина для нагрева, горячая распродажа

Автоматическая гидравлическая 3d cnc трубогибочная машина

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com