Промышленное гипсовое оборудование барабанная сушилка для угля с заводской ценой и высокой емкостью 2X24

- Категория: Поворотное оборудование для сушки >>>

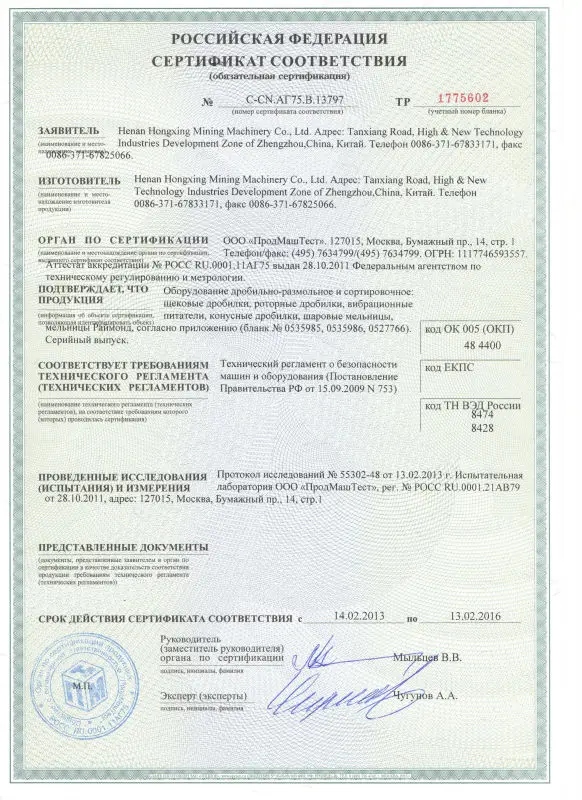

- Поставщик: Henan,Hongxing,Mining,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-15-2025 | 2457040.19 $* | 2506181.97 $* |

| Jul-15-2025 | 1992717.2 $* | 2032571.30 $* |

| Jun-15-2025 | 2418346.41 $* | 2466713.37 $* |

| May-15-2025 | 2398999.98 $* | 2446979.82 $* |

| Apr-15-2025 | 1915330.66 $* | 1953637.47 $* |

| Mar-15-2025 | 2360306.9 $* | 2407512.85 $* |

| Feb-15-2025 | 2340959.72 $* | 2387778.76 $* |

| Jan-15-2025 | 2321612.59 $* | 2368044.66 $* |

Характеристики

Industry gypsum rotary drum dryer equipment

1.Introduction of Industry gypsum rotary drum dryer equipment

The drum dryer is mainly used for drying materials with some moisture and granularity in ore beneficiation, building material, metallurgy and chemical department.

Rotary dryer has high adaptability to the materials so that it can be used for drying all kinds of materials, and in addition, the operation of this equipment is simple and reliable, for this reason, it get wide application.

2.Advantages of Industry gypsum rotary drum dryer equipment

♦ Compact structure;

♦ Reasonable layout, good drying effect;

♦ Small basis investment, which is only half of the same production monocular dryer;

♦ Reliable operation;

♦ Low energy consumption;

♦ high thermal efficiency;

♦ Automation control reduces the operating personnel, saving labor resources.

♦ The outlet temperature is low and the dust removal device has long service life.

3.Working principle of Industry gypsum rotary drum dryer equipment

The heat source of the drum dryer comes from the combustion device and this dryer uses co-current heating method, so that when the materials to be dried go into the cylinder from the feeding box or feeding chute, they are pushed back by the spiral lifting board.

Since the drum dryer is obliquely installed, the materials flow to the lower end of the machine under the gravity and the rotation of the machine, and on the other hand, the materials are repeatedly lifted by the lifting board to the higher end and then spread down constantly, so that the materials will form a even curtain inside the cylinder and conduct heat exchange with the hot air inside the cylinder.

Since the materials constantly spread and the water contained in them will be dried, thus achieving the aim of drying.

4.Technical parameters of Industry gypsum rotary drum dryer equipment

Delivery

We have developed long and good relationship with many shipping agents. Ocean freight partners are: APL, COSCO, OOCL, CSCL, MSC, etc. and train shipping is also available. The perfect shipping way and best service with lowest price are always provided for customers.

1. We are Factory ( NOT Dealer )

All machineries from Henan Hongxing Mining Machinery Manufactory are made by ourselves, with lower price, good quality and assured full after service.

So please buy machine from factory.

2. Training & Service

Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

3. If you are new for this business, we will help you

Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments.

4. We’d like to recommend a suitable type for you and send you a best quotation.

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com