Автоматическая Мини дойпак упаковочная машина преформированный мешок палочки заполнения уплотнения линия для

- Категория: Упаковочная линия >>>

- Поставщик: Top,Y,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.43 $* | 0.17 $* |

| Aug-15-2025 | 0.7 $* | 0.69 $* |

| Jul-15-2025 | 0.83 $* | 0.12 $* |

| Jun-15-2025 | 0.35 $* | 0.27 $* |

| May-15-2025 | 0.91 $* | 0.38 $* |

| Apr-15-2025 | 0.35 $* | 0.37 $* |

| Mar-15-2025 | 0.94 $* | 0.25 $* |

| Feb-15-2025 | 0.54 $* | 0.27 $* |

| Jan-15-2025 | 0.23 $* | 0.82 $* |

Характеристики

Products Description

Automatic Mini Doypack Packaging Machine Preformed Bag Pick Fill Seal Packing Machine Line for Food

MDP-series, The Japan Mitsubishi PLC control, with Delta touch screen interface system, easy operation, convenient operation, variable speed, multi function packing machine.

Mini doypack machine: the machine for your current and future needs! The functions of the packing system mainly are conveying, weighing, filling and bag sealing. The flexibility of it allows you to customize your machine to meet your individual requirements!

Doypack machine is suitable for all kinds of the premade bags, such as stand up pouch, zipper bag, box pouch, kraft paper bags, corner spout bags and so on

Besides, by connecting with different weighing equipment, the packing system can handle various products, such as powder, snacks, dried vegetable or fruit, puffed food, liquid sauce, beverage, etc

Doypack machine is suitable for all kinds of the premade bags, such as stand up pouch, zipper bag, box pouch, kraft paper bags, corner spout bags and so on

Besides, by connecting with different weighing equipment, the packing system can handle various products, such as powder, snacks, dried vegetable or fruit, puffed food, liquid sauce, beverage, etc

Product Paramenters

Specification of MDP Doypack Machine

Model No. | TOPY-MDP1 | TOPY-MDP2 | TOPY-MDP3 | ||

Bag Width | 70-280mm | 70-280mm | 70-330mm | ||

Bag Length | 80-320mm | 80-440mm | 80-440mm | ||

Bag Type | Stand-up bag, pillow bag | ||||

Power Supply | 110V/220V/380V/415V, 50/60HZ | ||||

Air Consumption | 7.0 CFM@80 PSI 0.14m3/m3 | ||||

Pneumatic Parts | PIAB Vacuum Generator, Pneumatics component Airtac from Taiwan | ||||

Advantage of TOPY Premade Bags Doypack Packing Machine:

1. Easy to operate, adopt advanced PLC from Japan Mitsubishi, mate with touch screen and electric control system, the man-machine interface is friendly.

2. Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials.

3. Safety device: Machine stop at abnormal air pressure, heater disconnection alarm

4. The width of the bags could be adjusted by electrical motor.

5. It matches with the glass safety door. The machine will stop working when you open the door. So that it could protect the safety of operators. At the same time, it could prevent dust.

6. The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification

7. With different feeders changed to pack solid, liquid, thick liquid ,powder and so on

8. The packing bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on Preformed bag made by film and paper.

2. Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials.

3. Safety device: Machine stop at abnormal air pressure, heater disconnection alarm

4. The width of the bags could be adjusted by electrical motor.

5. It matches with the glass safety door. The machine will stop working when you open the door. So that it could protect the safety of operators. At the same time, it could prevent dust.

6. The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification

7. With different feeders changed to pack solid, liquid, thick liquid ,powder and so on

8. The packing bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on Preformed bag made by film and paper.

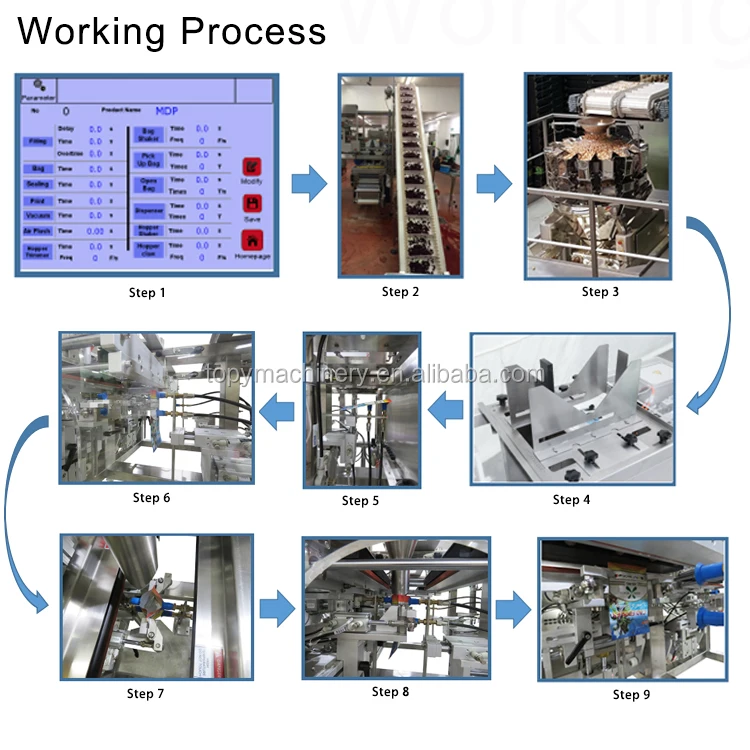

Working Process

Step1, set the parameters we need on HMI

Step2, pour bulk products into the storage hopper manually or automaticallyStep3, multifunction weighing dosing machine will dose target weight we need

Step4, put bags into bag magazine

Step5, zipper device open the ziplock

Step6, positioning bags to the filling station

Step7, bag open and sending out “request filling” signal

Step8, filling machine drop down products with target weight into open bags

Step9, the sealing jaws seal bags automatically

Packing Solution

Application and packing solutions:

The packing system showed here is just for your reference. We will offer you best solution according to your product mobility, viscosity, density, volume, dimensions etc.

Solid Packing SolutionCombination multi-head weigher is specialized for solid filling such as candy, nuts, pasta, dried fruit and vegetable etc.

Granule Packing Solution

Volumetric Cup Filler, linear weigher are specialized for granule filling such as chemical, beans, salt, seasonings etc.

Liquid Packing Solution

Piston Pump Filler is specialized for liquid filling such as water, juice, laundry detergent, ketchup etc.

Piston Pump Filler is specialized for liquid filling such as water, juice, laundry detergent, ketchup etc.

Powder Packing Solution

Servo Screw Auger Filler is specialized for powder filling such as nutrients powder, seasoning powder, flour, medicinal powder etc.

Servo Screw Auger Filler is specialized for powder filling such as nutrients powder, seasoning powder, flour, medicinal powder etc.

MDP Doypack Packaging Machine is suitable for various bags

More Products:

Combined with multihead weigher

Combined with linear weigher

Combined with bowl conveyor

Company Profile

TOP Y MACHINERY Co., LTD was founded in October 2011 in Lunjiao Town, Foshan City, and then we moved to Qide Industrial Park, Beijiao Town. We are integrated company with R&D, building, marketing and providing after-sale services backup. We are dedicated in producing all packing machines:

1. MDP bag given mini doypack machine for preformed pouches.

2. VP vertical forming filling sealing machine for roll of film.

3. VW linear weigher for granules weighing and filling.

4. Powder packaging systems.

5. Granule packaging systems.

6. Liquid packaging systems.

7. Auxiliary conveyors.

and turnkey material handling, weighing, packaging and inspecting solutions for granule, powder and liquid. These products are widely used in foods, medicines, chemicals, toys and ironware industries.

TOP Y MACHINERY Co. believes in machine innovation and design. We gather up persistent efforts and technology to aim at customers’ satisfaction quality. We are keen to better detailed design and engineers work on every working stage in the drafts. In the working shop the workers assemble the whole machine by batches to make sure each batch works well first. “Customers First” to ensure customers get good quality machines and also let us win good reputation in customers. We are ready to provide quality machines and sincerely hope to have chances to cooperate with you.

Certifications

FAQ

Q1: How to find a Packing machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to pack?

2. The bag/sachet/pouch size of you need for the product packing ( the length, width).

3. The weigh of each pack you need.

4. You requirement for the machines and the bag style.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you.

In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placking the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality.

And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use alibaba trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process?

1.Sign the Contact

2.Arrange 50% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Tell us about your product details and packing requirements.

1. What kind of product you would like to pack?

2. The bag/sachet/pouch size of you need for the product packing ( the length, width).

3. The weigh of each pack you need.

4. You requirement for the machines and the bag style.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you.

In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placking the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality.

And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use alibaba trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process?

1.Sign the Contact

2.Arrange 50% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Contact Us

Похожие товары

Системы упаковки и укладки

US $40000-$80000

Автоматическая оберточная упаковка для коробки и картонной коробки

US $55000-$65000