Высокоприбыльная производственная линия для производства картофельных чипсов и фритюрницы с

- Категория: >>>

- Поставщик: Jinan,Keysong,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.65 $* | 0.84 $* |

| Aug-17-2025 | 0.30 $* | 0.6 $* |

| Jul-17-2025 | 0.31 $* | 0.16 $* |

| Jun-17-2025 | 0.37 $* | 0.55 $* |

| May-17-2025 | 0.86 $* | 0.59 $* |

| Apr-17-2025 | 0.64 $* | 0.3 $* |

| Mar-17-2025 | 0.12 $* | 0.50 $* |

| Feb-17-2025 | 0.41 $* | 0.80 $* |

| Jan-17-2025 | 0.18 $* | 0.96 $* |

Характеристики

High profit production line for making potato chips and french fryer with CE

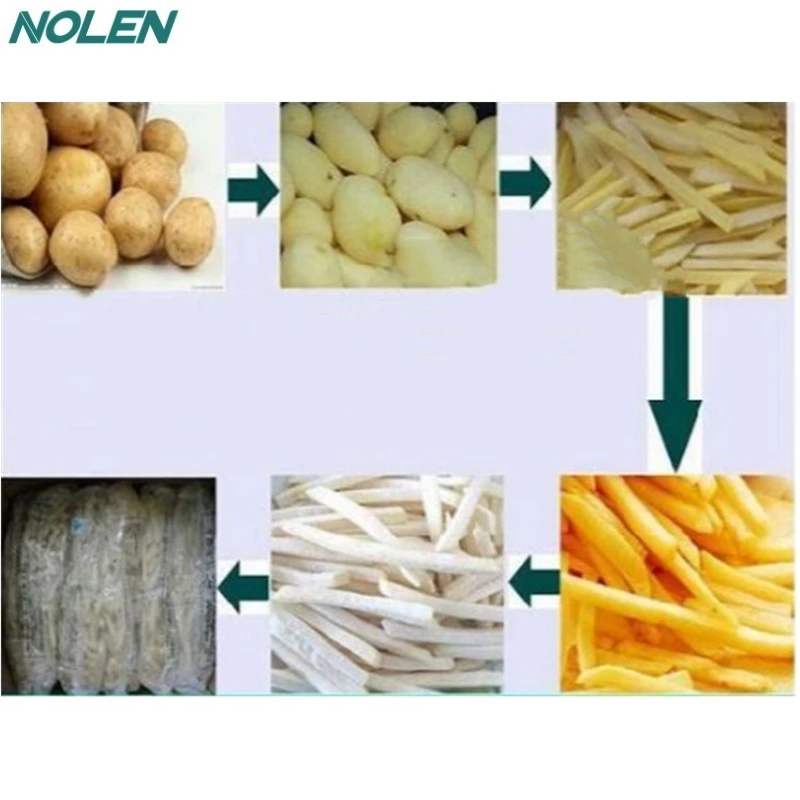

1.Description of the french fries making machine:

We can provide semi-automatic and fully automatic potato chip production line according to customer's requirements. The conventional output is 100kg/h, 150kg/h, 200kg/h, 300kg/h,500kg/h, 1000kg/h and so on.

1.washing and peeling machine

2.cutting machine

3.blanching machine

4.dewatering machine

5.frying machine

6.deoiling machine

7.freezing/

7.flavoring machine

8.packing machine

2.Parameter of the 100kg/h potato chips machine:

Name | Power(kw) | Voltage(v) | Weight(kg) | Size(mm) | Capacity(kg/h) |

washing and peeling machine | 1.1 | 220/380 | 210 | 1400*850*800 | 200 |

cutting machine | 1.1 | 220/380 | 110 | 950*900*1000 | 600-700 |

blanching machine | 24 | 220/380 | 120 | 1200*700*950 | 100 |

dewatering machine | 1.1 | 220/380 | 390 | 1000*800*850 | 200 |

frying machine | 24 | 220/380 | 120 | 1200*700*950 | 100 |

deoiling machine | 1.1 | 220/380 | 390 | 1000*800*850 | 200 |

flavoring machine | 1.1 | 220/380 | 190 | 1100*800*1300 | 300 |

packing machine | 1.5 | 220/380 | 260 | 1200*600*850 | 300 |

1.washing and peeling(different type):

Brush cleaning and peeling machine is suitable for carrot, ginger cleaning and peeling and electric potato cleaning and peeling machine related to hard vegetables.

It uses the rotation of the hair roller to remove the dirt attached to the carrots and other vegetables. The large brush potato peeling machine is provided with a spray water pipe on the upper part of the peeling machine, and the brush cleaning and peeling machine can spray and rinse the materials. At regular intervals, turn on the electric potato cleaning and peeling machine end discharge port, and remove the material.

2.cutting(different model):

The potato cutting machine mainly comprises a frame, a casing, a feeding tray, a cutter, a transmission part and a discharge cover.

When it is working, the potato material is put into the hopper, and the material is rotated along the wall of the casing by the pouring trough on the rotating dial. The cutter mounted on the wall of the casing cuts the vegetables into strips and cuts the potatoes. The potato chips come out of the discharge cover.

3.blanching(different model):

Potato blanching machine is mainly used for fruit, root vegetables and carrots, asparagus, mushrooms, fruit slices and other products. It is an indispensable equipment for pre-treatment such as quick-freezing, dehydration and freeze-drying.

4.dewatering(different model):

4.dewatering(different model):

It mainly use for drying the cleaned material with multiple small fans.

Dehydrator: Dehydration by centrifugal force. Dehydration before frying can greatly shorten the frying time and improve the taste of the potato chips. Improve production efficiency and reduce production costs.

5.frying(different model):

It is mainly used for slightly fried potato chips.

Oil-water mixing fryer: This equipment is an advanced frying equipment. Because the specific gravity of water and oil is different, the water is below, the oil is fried in the upper layer, and the residue is directly deposited in the water. The oil does not emit black smoke, which greatly prolongs the life cycle of the oil and greatly reduces the cost. The oil temperature control ensures the quality and taste of the potato chips. After the work is finished, the water is released and the residue will flow out along with the water.

6.deoiling machine(different model):

Deoiler:centrifugal deoiler, deoiling freshly fried potato chips (strips), overcoming the defects of high oil content and greasy mouth of potato chips. Improve the taste of potato chips (bars).

7.flavoring(different model):

automatic seasoning machine: drum type seasoning machine is made of stainless steel. The potato chips (strips) are evenly turned during the rotation of the drum, and the seasonings are added by sprinkling or spraying. Seasoning is not easy to break.

8.freezer(different model):

9.packing(different model):

Nitrogen-packing machine: When packing, the bag is filled with nitrogen gas, which can effectively prevent the potato chips (strips) from being broken and prolong the shelf life. Inflation, packaging, and coding are completed at one time.

3.Packaging and shipping:

Every machine is packed with great care and tough material. It is packed with cling films first and then film bags. At last, it is packed with wooden case which is reinforced with the iron bar on the top and bottom.With this kind machine, all our laser machine can protect well during long trip by sea or by train.We can transport machine by boat or by training, according to your requirement.

4.Competitive Advantages:

1. Guaranty: One Year.

2. One set of consumable accessories will be provided with the machine.

3. Any question, you can mail/call us at any time. And our most experienced engineers are assigned to give consulting service, and always available for dispatching abroad.

4. All spare parts are always available for delivery.

5. Manual is in English.

6. Minimum order: 1 set

7. Prompt Delivery: 15-20 working days after receiving deposit

8. Installation: sending one technician to the customer's factory for installation and training.

9. Packaging: firstly packing with plastic inner side, then strengthening with wooden case outside.

5.Company Information:

Keysong was founded in 2013. Specializing in producing food machines for more than 6 years. Since its inception, it is specializing in the manufacture, research, development, sales and after-sales of food extrusion machine, puffed food production line, fruit and vegetable washing and drying processing line.

Our History:

In 2013, Keysong was established, concentrating on manufacturing and selling extrusion snack production line at home and abroad.

In 2014, Keysong broke traditional breakfast cereal production technology, and invented new production process.

In 2015, Keysong moved to a new workshop, which covers the area of 5000 square meters. In 2015, we have our agency in India, Nigeria, Thailand, Morocco and Algeria.

In 2016, Keysong cooperated with Shandong Liwei Microwave equipment, started researching on food microwave drying technology. In August, 2016, Keysong build a team, concentrating on researching on the technology of vegetables and fruits washing, cutting, drying and freezing. And has received great results till now.

6.About us & more details:

MOQ | 1 set |

Supply Ability | 20 sets per Month |

Shipping port | Qingdao port, Shandong, China |

Packing details | Fumigation-free wooden case outside, stretch film inner |

Relevant spare parts | free, delivery with processing line |

Guarantee | Within 12 months |

Oversea service | Provide installation and commissioning after machine arrived your factory |

Payment terms | 30% is paid by T/T as the down payment, 70% is paid by T/T or L/C before shipment. |

Delivery time | 30 days after receipt the deposit |

Pre-shipment | When it finished, we will invite you to our company to inspect machines, when no problem, we will arrange the shipment |

FAQ:

1. How about the documents after shipment?

After shipment, we'll send all original documents to you by DHL/TNT, including Packing List, Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

For standard machines, it would be20-30 days; For non-standard machines and customized machines according to client's specific requirements, it would be 30-45 days.

3. Do You Arrange Shipment For The Machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

4. How is the packing?

Water-proof plastic film package with foam protection in each corner Solid Seaworthy Wood Box Package with Steel Belt Save space as much as possible for container loading

Please feel free to contact us:

Jinan Keysong Machinery Co., Ltd.

Holly Huo

Tel/Whatsapp/Wechat: +86 155 5006 3605

www.foodmachinefactory.com