LDPE PE PP used Film recycling Plastic Scrap recycle Washing

- Категория: >>>

- Поставщик: Zhangjiagang,Boxin,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.32 $* | 0.97 $* |

| Aug-17-2025 | 0.80 $* | 0.34 $* |

| Jul-17-2025 | 0.63 $* | 0.36 $* |

| Jun-17-2025 | 0.60 $* | 0.30 $* |

| May-17-2025 | 0.3 $* | 0.67 $* |

| Apr-17-2025 | 0.13 $* | 0.43 $* |

| Mar-17-2025 | 0.46 $* | 0.85 $* |

| Feb-17-2025 | 0.9 $* | 0.69 $* |

| Jan-17-2025 | 0.24 $* | 0.49 $* |

Характеристики

The pellets products could be used for new plastic products manufacturing again.This line is controlled with a central electrical control panel from the beginning to the end.

A typical PP PE film washing plant is consist of the following components:

1. Belt conveyor: For waste material infeeding.

2. Shredder: For material size reduction. Single shaft shredder & Double shaft shredder could be all choosed as per different plant's needs.

3. Crusher/Granulator: Wet crushing system.It used for material size reduction and pre-washing.

4.High speed Friction washer( Scrub washing machine): High speed friction washing could achieve a good cleaning effects through the blades on the beating and spray. This machine is suitable for broken film and Plastic flakes washing.

5. Sink & Float separation tank: for impurities precipitating separation and wash the material more clean.

6. Horizontal dewatering machine( Dehydrator):This machine is mainly used for the cleaning of waste plastic after mechanical dewatering and drying, the spindle through high speed rotating threw the plastic and water to the screen, water releases by screen, while the plastic is from the outlet to be out of the machine enters into the next procedure. The machine has a good drying effect and high energy efficiency. The blade is made of high wear-resistant materials, can be replaced more conveniently.

7. drying pipes & transition silo: Hot air drying and transportation to final storage silo.

The whole line is automatically controlled from feeding to drying.

Application ranges: PE, PP film, bottles, bags, woven bags, sacks ect.

Features:

1. Final products has good quality.

2. The whole line capacity between 200kg/h-2000kg/h.

3. Washing machine Parts which contact material use SUS304 with high thickness to ensure long service lift time

4. World famous brand components applied on the production line- famous brandbearing, Siemens contactor, RKC temperature, ABB inverter, Siemens PLC control etc

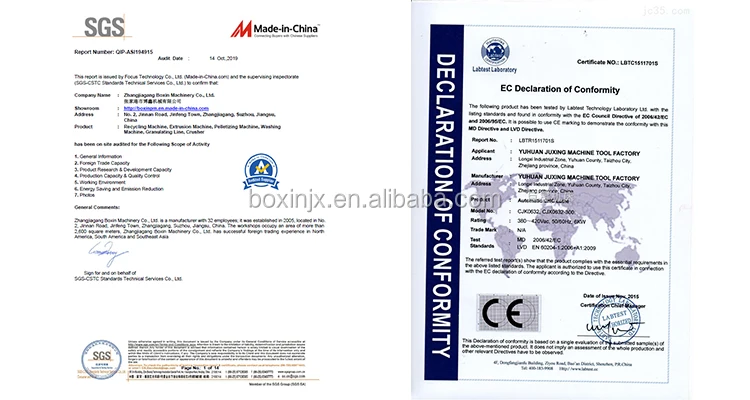

5. The whole production line with CE ,ISO9001 certification After discussion with our customers, We can provide effective, customized proposals and turn-key solutions by listening to and understanding our customers’ needs.

Customers are warmly welcomed and encouraged to visit our factory to check some machines in operation.

Any more detailes you need, please feel free to contact with us.

Model | BXPEPP-300 | BXPEPP-500 | BXPEPP-1000 | BXPEPP-1500 |

Capacity (KG/H) | 300 | 500 | 1000 | 1500 |

Water consumption(T/H) | 2--3 | 3--4 | 4--5 | 5--7 |

Power Consumption(T/H) | 130--160 | 210-260 | 300-350 | 400-460 |

Staff(person) | 2-3 | 2-3 | 3-5 | 3-5 |

Factory Area (M2) | 30*4*5 | 40*4*5 | 45*6*5 | 55*6*5 |

LDPE film scrap washing line is widely used to treat PP/PE plastic waste mixed material into clean film flakes, which include waste PP woven bags, PP non-woven bags, LDPE film, plastic garbage, waste plastic mulch film. After films cleaned, you can make them to be granules with next process which is called pelletizing line. This production line is high automatic operating and save labor cost and low after maintenance. With advanced international industry concepts and technologies to meet waste plastic recycling at home or abroad.

Crusher & Friction machine

For crushing the material into smaller size.

Get rid of the sand and dirties with injecting water.

The parts which contacts with flakes is made of SUS304.

Blower drying system&De watering machine

For drying film flakes.

The temperature is adjustable by temperature

controller.

For reducing water content.

Continuously discharge the material from

side and drainage from the bottom of this

machine

The contact part with the material is made of stainless steel.

Floating washing tank

To remove sand and dirties.

The floating washing tank with water level control device.

Parts contact with material are made of stainless steel 304.

Double outlet hopper

For temporary storage for

flakes.

Made of SUS304.

Features of film washing recycling line:

1.\tThe moisture of final products will be less tan 8%, so that the washed materials can be stored easily.

2.\tThe electric components are from the famous brand in China ( or customer designated ).

3.\tThe complete line is with high level of automation, CE certification, steady performance and high working efficiency.

4.\tThe reasonable design, harmonious colors.

BOXIN's film recycling line mainly for LDPE film, PP woven bags, PP non-woven, PE bags etc. crushing and washing.

The film recycling line includes equipment of crusher, floating washer, hot washer, high speed friction washer, dryer, packing system, etc. Modular design principle applied into the washing system. BOXIN can freely combine each standard modules into the system to enhance the washing performance;

1.For the loose cargo the machine will be packed by wooden box .

2.For the full container loading the machine will be packed by wooden pallet and film scraping .The electrical control panel will be always packed by wooden box .

Zhang Jiagang Boxin Machinery Co.,Ltd is leading supplier of complete waste plastic recycling systems. We are specialized in producing PET bottle recycling line, PP, PE film and flake recycling line, different kinds of plastic granulating line, series crushers, shredders and ect. Since we are established in 2005 we are pursuing to development and manufacture outstanding quality of waste plastic recycling equipment through excellent manufacture and quality inspection process time and again.

Up to today, our machines and service are supplied in more than 30 countries all over the world.

We are sincerely to cooperate with you in the future!

PP/PE film/rigid scraps washing line Before-sale

1.\tIntroduce products and applications detain

2.\tRecommend suitable solution

3.\tProvide with reference information

4.\tOffer lab for test

During Manufacturing

1.\tProvide with layout and engineering conditions

2.\tInform the project processing status

3.\tOffer other documents

After-sale

1.\tProvide with installation, commissioning and training

2.\tRegister and record customer information

3.\tOffer spare parts

4.\tProvide with necessary technical support for new application

5.\tVisit customer regularly and correct information