Полностью автоматическая машина для производства одноразовых картонных коробок прайс-лист изготовления

- Категория: Paper Production Machinery >>>

- Поставщик: Ruian,Daqiao,Packaging,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 29750.72 $* | 31238.42 $* |

| Aug-17-2025 | 29500.46 $* | 30975.99 $* |

| Jul-17-2025 | 24750.63 $* | 25988.66 $* |

| Jun-17-2025 | 29000.94 $* | 30450.97 $* |

| May-17-2025 | 25250.0 $* | 26513.5 $* |

| Apr-17-2025 | 28500.78 $* | 29925.95 $* |

| Mar-17-2025 | 28250.54 $* | 29663.12 $* |

| Feb-17-2025 | 28000.5 $* | 29400.89 $* |

| Jan-17-2025 | 27750.80 $* | 29138.33 $* |

Характеристики

HBJ-D series automatic paper carton erecting machine is an ideal choice to produce hamburger boxes, French fries box, food tray, lunch box, Chinese noodle box, hot dog box, etc. It adopts micro-computer, PLC, alternating current frequency converter, the vacuum-sucking and servo motor paper feeding, auto gluing, automatic paper tape counting, and chain drive. All of these main parts and electric control system adopts imported brand to guarantee steady working, precise positioning, smooth running, safety and reliability operation

It can make more than 10 types boxes. If the box is not in blow list, please show us your sample.

Technical Specification:

Type | HBJ-D800 | HBJ-D1200 | HBJ-D2000 |

Production capacity | 50-180 pcs/min | 80-320pcs/min | 100-300 pcs/min |

Suitable Material: | 200-600g/m2 card paper,PE coated paper, kraft paper, corrugated paper | ||

Length: | L100-450mm,degree:5°-40°

| L100-450mm,degree:5°-40° | L100-450mm, degree:5°-40° |

Width: | 100-600mm | W100-400mm | B100-600mm |

Hight: | 15-200mm | H15-200mm | H15-200mm |

Total Power: | 5KW | 6.25KW | 3KW |

Total Weight: | 1.8T | 2.8T | 2.2T |

Overall Dimension: | 3600 x1400 x 1700 mm | 3600 x 1850 x 1700 mm | 2300 x2200 x 2100 mm |

power source: | 380V /220V 50HZ | 380V 50HZ | 380V 50HZ |

Advantages of new type

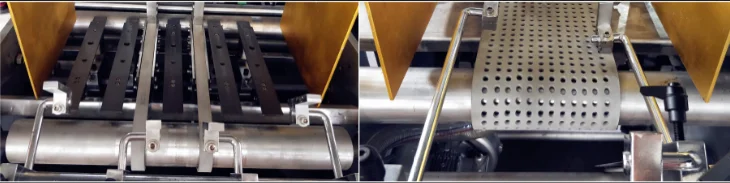

1.To improve the feeding paper stability and change molds more convenient. We use wider belt instead of two narrow belts. Narrow belt is easily abraded by papers. Also you should adjust the distance of two belts when you change the molds. For wide paper, it is more endurable and don't need be adjusted.

2.Automatic glue system is controlled by reduce motor from Taiwan. Glue point we use sponge point, which is easy to cut the shape to fit with different products needs.

3.It adapts counting paper tape equipment to count product quickly and accurately.

4.In order to feed paper more automatically, we use both PLC operations with photoelectric sensor and servo motor to control the paper feeding part. It has two advantages.

It makes feed paper part easily operate when you change the moulds. The old design is adjusted by cam. When you change the different size of moulds, we need replace different size of cams. It is very complex and takes much time for change.

It makes paper feeding part more smoothly and fluently working. The old design is easily missing paper feeding when machine running.

4.In order to feed paper more automatically, we use both PLC operations with photoelectric sensor and servo motor to control the paper feeding part. It has two advantages.

5.The frame of collecting box is separated into three parts, each part can be opened. It is easier for changing moulds or repairing.

A list of samples