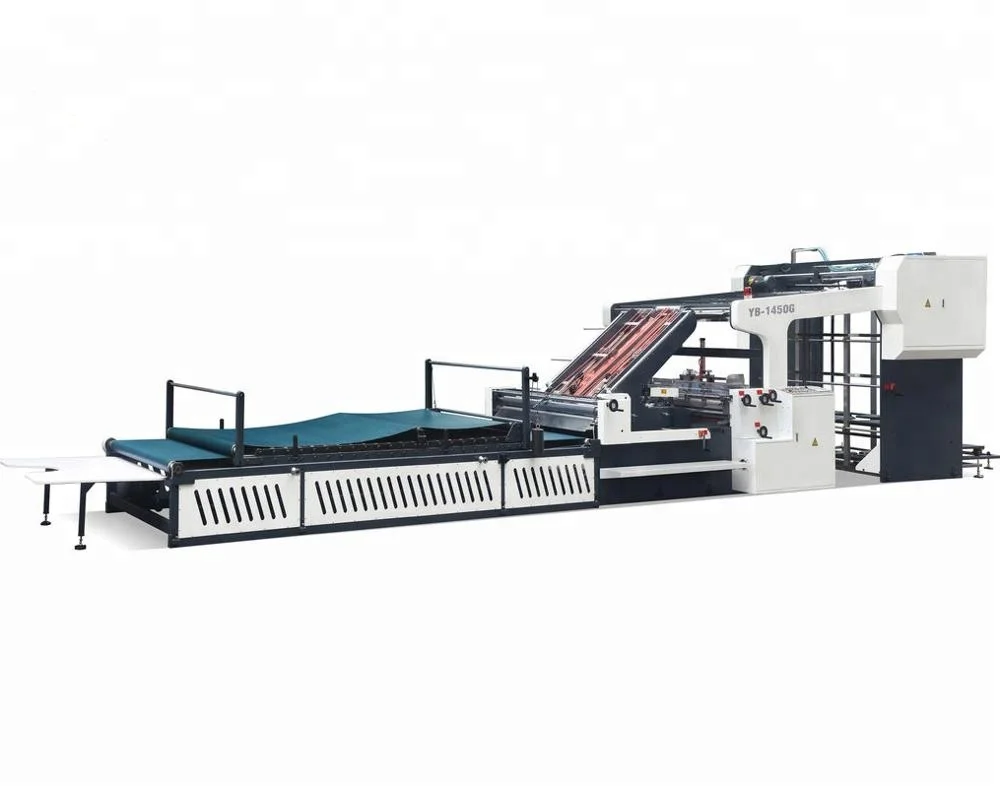

Автоматическая машина для ламинирования гофрированного

- Категория: Упаковочные формовочные машины >>>

- Поставщик: Cangzhou,Quanheng,Imp,&,Exp,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 23800.27 $* | 24990.62 $* |

| Aug-19-2025 | 23600.41 $* | 24780.97 $* |

| Jul-19-2025 | 19800.43 $* | 20790.62 $* |

| Jun-19-2025 | 23200.72 $* | 24360.25 $* |

| May-19-2025 | 20200.33 $* | 21210.33 $* |

| Apr-19-2025 | 22800.79 $* | 23940.34 $* |

| Mar-19-2025 | 22600.53 $* | 23730.36 $* |

| Feb-19-2025 | 22400.67 $* | 23520.35 $* |

| Jan-19-2025 | 22200.27 $* | 23310.38 $* |

Характеристики

Automatic Carton Flute Laminating Machine

Model | BZJ-1300L | BZJ-1450L | BZJ-1600L |

Maximum size | 1300×1100mm | 1450×1100mm | 1600×1100mm |

Minimum size | 400×400mm | 400×400mm | 400×400mm |

Appropiate paper |

|

|

|

Max Speed | 6000Sheets/h | 6000Sheets/h | 6000Sheets/h |

Total power | 13kw | 13kw | 13kw |

Overall dimension | 12000×2250×2655mm | 12000×2400×2655mm | 12000×2550×2655mm |

Automatic Carton flute laminating machine are designed for laminating cardboard and cardboard, cardboard and corrugated board (Flute shape A, B, C, D, E, F and N), 3-layer, 5-layer, or 7-layer corrugated paperboard all can be laminated smoothly and accurately. Famous internal or foreign foreign manufacturers make all the main components with long service life and excellent stability. Electrical components of internationally known brands are adopted to ensure reliability of running.

This machine features stability, high precision, easy operation, saver of time and labour, maintenance of convenience, etc

Performance of the machine:

1, The machine adopts unique pressing spring front lay registration design complain with PLC control system with makes run at high lamination precession and low rate of breaking down.

2, The machine uses frequency converter for speed regulation, PLC central, simulation to digit program system

Double servo motors are used to control bottom sheets to get to the front lay timely and accurately. Thus the machine accuracy is ensures even in operation adjusting conditions.

3, Balance-tested rollers, tight assembling technique, plus timing belts driving mechanic system makes the machine run at low noise with high precision.

4, The machine adopts automatic glue supply and recyclable glue decollating system.

5, Self-developer high-strength feeder complaint with high configuration electric system.

6, The electric parts used are all word side available brand or well-known Chinese brand.

7, All material are inspected according to ISO-9001 standard and the key parts such as besting are importanted ones.

8, The face sheet for this machine can be 150-450GMS,The bottom sheet can be A,B,C,D,E,F flue corrugators sheet as well as 3 ply board or 5 ply card board with the maximum thickness not more than 8mm

1.Pre-Sales Service:

Our service team will glad to reply inquiry and consulting support in every way as soon as we can.

2. Package & Delivery

Our service team will pack goods under export standard, and prepare delivery in time as agreement.

3.Technical Support:

To ensure you get a top-notch experience, we can send our engineers to help you install properly, as well as provide local training for your employees.

Our service team will give you 24 hours support, and technical guidance by email, telephone, what's app and fax for regular maintenance and support.

Q: How does your factory do regarding quality controlling?

1) All raw material we used are environmental-friendly

2) Skillful workers care every details in handling the producing and packing process

3) Quality control department are specially responsible for quality in each process

We produced high quality products by introducing advanced technologies for over 20 years, and our products are also widely exported to many different countries including Russia, the Middle East, Africa, Southeast Asia, EU, etc, earned a high reputation among the customers.

Q:Can I customized the machine from your company?

A: Of course you can,we can manufacture the machine based on your customsized requirement.