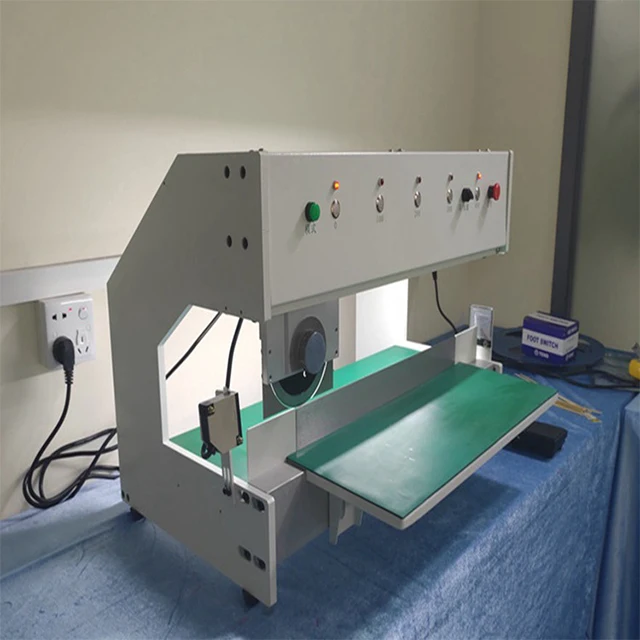

Автоматическая машина ножного типа SMT для резки алюминиевой подложки печатной

- Категория: Оборудование для производства электроники >>>

- Поставщик: Shenzhen,Shengdian,Electronic,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 1785.43 $* | 1874.6 $* |

| Aug-16-2025 | 1770.23 $* | 1859.79 $* |

| Jul-16-2025 | 1485.54 $* | 1559.29 $* |

| Jun-16-2025 | 1740.43 $* | 1827.75 $* |

| May-16-2025 | 1515.38 $* | 1591.85 $* |

| Apr-16-2025 | 1710.34 $* | 1796.72 $* |

| Mar-16-2025 | 1695.43 $* | 1780.22 $* |

| Feb-16-2025 | 1680.17 $* | 1764.56 $* |

| Jan-16-2025 | 1665.9 $* | 1748.16 $* |

Характеристики

Features

1.Full automation,stable performance,easy operation,high safety and simple maintainence.

2.Uniquie shape,practical operation,and gorgeous appearance.

3.Cutting principle is based on Motor data transfer, blade moving to cut PCB.

4.Suitable for all V-CUT PCB board. PCB thickness:0.2-3.2mm, PCB v-cut thickness:0.2-2.0mm.

5.During cutting,it can effectively decrease physical strength to avoid welding spot cracking.

6.PCB remains still during cutting, thus to ensure personal safety.

7..Lower linear blade is used to fix the PCB v-cut, and upper circular blade moves to separate PCB.

1.The machine is designed specially to cut PCB boards of strip lights and back-light modules.

2.The machine is applicable for various substrates, such as FR4, Aluminum substrate, etc., and it is the best choice for Aluminum substrate.

3.The cutting depth of three cutters is increased stepwise to guarantee processed surface is smooth and processed substrate is free of deformation and bucking.

4.Due to the stepwise increase of cutting depth, the bending stress born by PCB board is too small to damage components on PCB boards.

5.PCB alignment is placed at left side of operation platform firstly, then pushed backwards against the location plate, and then moved right along the location plate into the cutting area, then PCB alignment moves forwards automatically till one individual PCB is cut out completely, and then remaining PCB alignment is placed at left side again to repeat previous processes.

6.Operator’s workload is reduced dramatically by the work platform due to its simple operation.

7.Its processing rate is highest among other competitive products.

Durable cutters are made from Sweden SKH-9 high-speed steel.

Specification

Model | YS-805A/YS-805B/YS-805C/YS-805D |

Max PCB length (mm) | 400/600/900/1300 |

Cutting Speed (mm/s) | 300/500 |

Cutting Thickness (mm) | 0.2-3.2mm |

Power Supply (V) | 110V /220V |

Size (mm) | 740x550x460/940x550x460/1200x550x460/1530x550x420 |

Weight (Kg) | 55/70/80/90 |

Blade working life for metal (Year) | 0.5 |

Blade working life for PCB (Year) | 1 |

Guarantee (Year) | 3 |

Delivery (Day) | 1-2days after receiving payment |

1 | |

Ability (Set/month) | 300 |