Линия по производству дробилок для древесных гранул большой

- Категория: Wood Pellet Mill >>>

- Поставщик: Zhengzhou,Dingli,New,Energy,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 23562.9 $* | 24740.69 $* |

| Aug-18-2025 | 23364.99 $* | 24532.67 $* |

| Jul-18-2025 | 19602.81 $* | 20582.70 $* |

| Jun-18-2025 | 22968.84 $* | 24116.52 $* |

| May-18-2025 | 19998.43 $* | 20998.28 $* |

| Apr-18-2025 | 22572.96 $* | 23701.62 $* |

| Mar-18-2025 | 22374.81 $* | 23493.35 $* |

| Feb-18-2025 | 22176.75 $* | 23285.24 $* |

| Jan-18-2025 | 21978.94 $* | 23077.38 $* |

Характеристики

Product Introduction

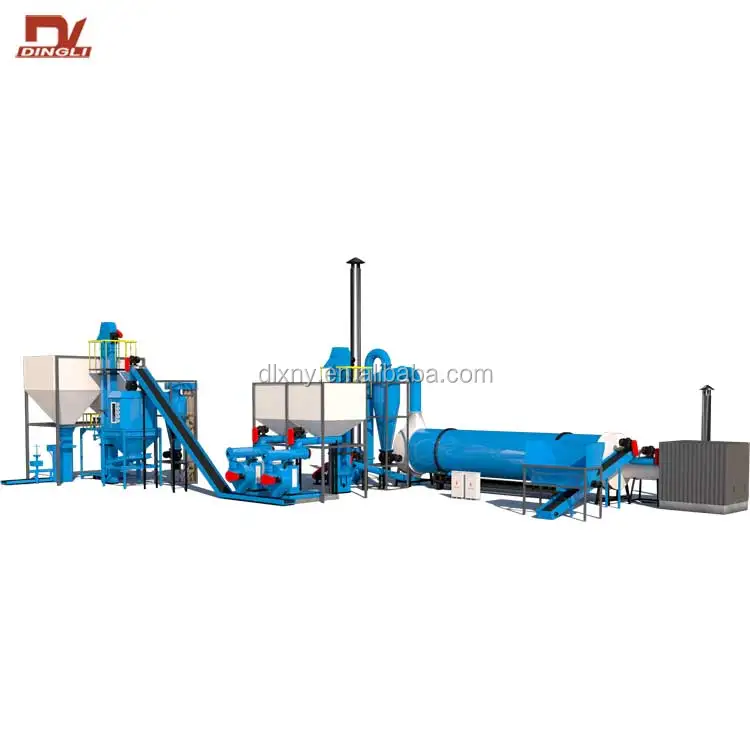

Because the biomass as fuels has no contamination, and other significant characteristics of renewable, thus it increasingly brought to the attention of the countries.

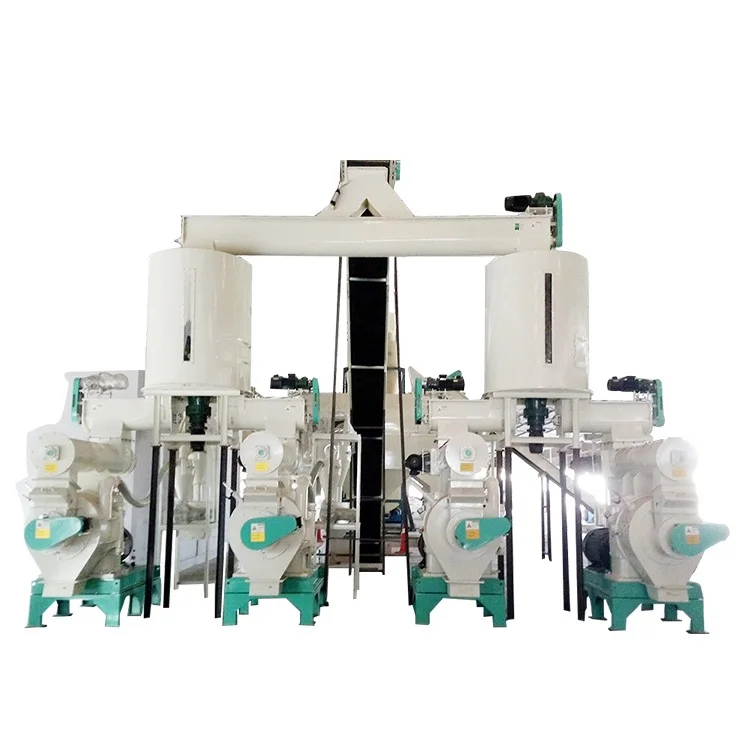

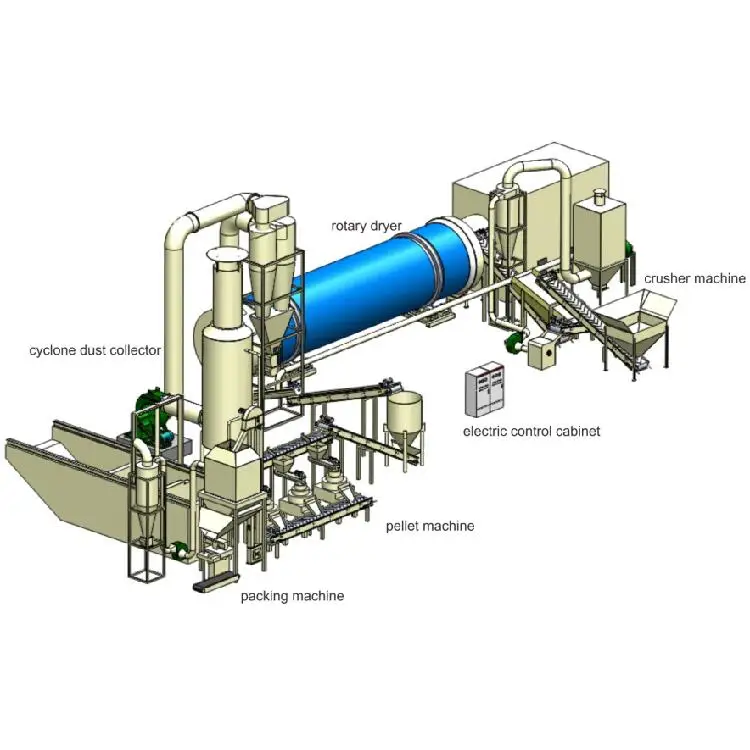

Complete Biomss Pellet Production Line consists of heater, feeding machine, rotary drum, discharging machine, induced draft fan, unloading feeder, cyclone, odor removal equipment and power distribution cabinet.

Product Application

Biomass Pellet Production Line is is used for various of material, such as wood powder, straw, wood chips, sawdust, corn straw, wheat straw, rice straw, cotton straw, peanut shell, branch, saw powder, bagasse, sunflower seed shell, bamboo shavings, wood shavings, barley straw, oat straw, rye, straw, sorghum straw, corn stalks, stem drying potato vines, beans, peanut vine,etc.

Main Features

1.Patent technology (patent no. : ZL200920089749.2), single equipment the kinds are variety, application to a variety of materials, modular structures, optimize configurations, ensure production lines broad applicability.

2.According to customer's requirements to realize intelligent control, a key "fool" type operation.

3.More than 300 users in the world, our factory has the rich practical experience.

4.The cover area reduce 50% than the traditional drying granulating production line , civil investment reduce about 50%.

5.waste gas discharge temperature is lower than 50 ℃, low energy consumption.

6.Particle shaping fuel rate of 98%, bulk density and high density.

7.Special design ash control technology, ash content lower than 1%.

8.Modular dust collecting and purifying heat recycling configuration, safe and protect environmental.

9.This type mixing drum dryer is supporting many new type energy-saving hot air stove,energy consumption drop about 30%,power consumption reduce 20%,lower operation costs.

10.Internet sharing system, it can ensure that the personalized production lines , accessories and unit efficient distributions in place.

Below is Pellet Production Line Process

Below is Working Principle

Model | DLKL1000 | DLKL1500 | DLKL2000 | DLKL3000 | DLKL5000 | |||||

Capacity(t/h) | 0.8-1.0 | 1.2-1.5 | 1.5-2.0 | 2.5-3.0 | 4.5-5.0 | |||||

Motor Power(KW) | 135 | 175 | 210 | 255 | 300 | |||||

Weight(T) | 45 | 47 | 55 | 68 | 73 | |||||

Plant Area(m) | 10m*24m | 10m*24m | 10m*24m | 12m*26m | 12m*26m | |||||

Except above models, we also can supply special model according to your requirements. | ||||||||||

Below is Dingli Group Packaging & Shipping:

Your device will be packed well in container and suit for long ocean shipping.

Below is Dingli Group Service Items:

Pre-sale

1. According to your needs, select right model for you.

2. According to your special requirements, design customized solution and manufacture customized products for you.

3. Welcome your visit.

Sale

1. Sign contract, pay deposit, we arrange production.

2. Product acceptance.

3. Help you formulate construction scheme.

After-sale

1. Assign engineer service for you on-site freely.

2. Install and adjust device, train how to operate.

3. After installation, leaving 1-2 technical staff to help you on-site production, until achieve customer satisfaction.

Below are Dingli Group Factory & Sales Team:

Below are Dingli Group Honors & Certificates & Patents:

Below are Dingli Customers Visiting:

Dingli Dryer Production Line has exported to over 30 countries with 300 foreign partners, such as Germany, Britain, United States, Italy, Israel, Chile, Thailand, Russia, Vietnam, India, Cambodia, Indonesia, Malaysia, Thailand etc.

Below are Installation Sites of Our Customers:

After reach deals, Dingli Engineer will fly to your address, install and adjust machine for you freely.

Also train you operation skills, until you are satisfied.