Лидер продаж машина по производству древесных гранул/мельница гранул/Производственная линия гранул изготовитель

- Категория: >>>

- Поставщик: Zhengzhou,Yufeng,Heavy,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 23800.86 $* | 24990.21 $* |

| Aug-15-2025 | 23600.81 $* | 24780.46 $* |

| Jul-15-2025 | 19800.75 $* | 20790.69 $* |

| Jun-15-2025 | 23200.83 $* | 24360.43 $* |

| May-15-2025 | 20200.92 $* | 21210.22 $* |

| Apr-15-2025 | 22800.68 $* | 23940.13 $* |

| Mar-15-2025 | 22600.49 $* | 23730.33 $* |

| Feb-15-2025 | 22400.43 $* | 23520.27 $* |

| Jan-15-2025 | 22200.39 $* | 23310.76 $* |

Характеристики

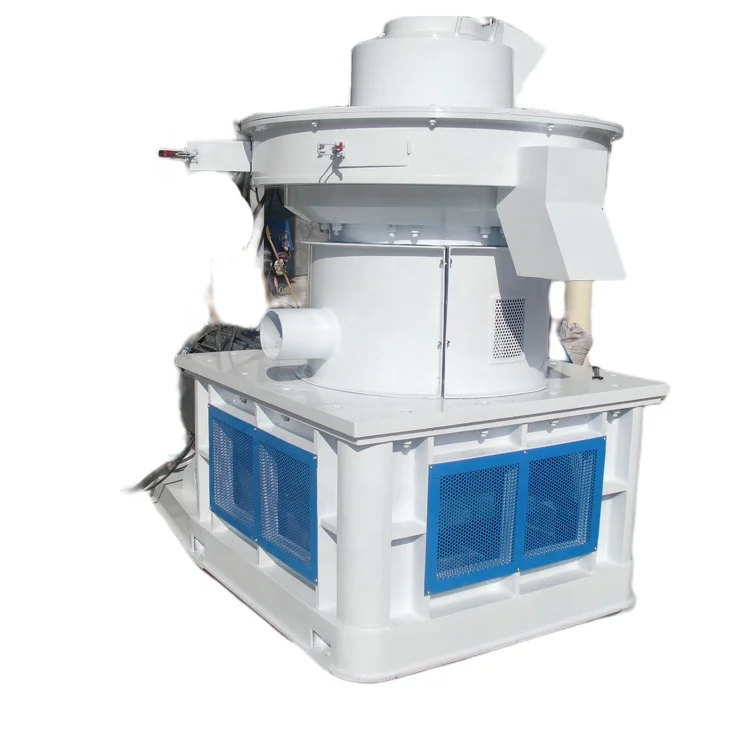

Hot sale wood pellet machine/wood pellet mill/wood pellet production line pellet maker equipment

The production line combined with process as Crushing, Drying, Pelletizing, Cooling and Packing. We provide complete pellet mill and briquetting system which are tailor-made, economical, efficient solution with latest technology.

As we know, various wood residues and other biomass materials can be processed into fuel pellets, but every raw material has its own characteristics during pellet production; therefore, to produce quality wood pellets and biomass pellets the raw material needs to have consistent quality suitable to produce quality pellets. We have experience in processing a wide range of biomass materials into pellets and their combustion results.

1. Ring die wood pellet machine ----Raw materials Prepared

Wood Pellets is mainly made of any wood waste and biomass particles, such as wood sawdust, wood shavings, wood chips, wood logs, straw, rice husk, coffee husk etc. At a wood pellet plant, raw material need to be well prepared before pelletizing, then get dried, compressed, and formed into small eraser-sized bits, the wood pellets get from wood pellet plant are clean, pleasant smelling and smooth to touch.

2. Ring die wood pellet machine ----Crushing process – Hammer mill

The hammer mill is a machine whose purpose is to crush materials by the collision between the high-speed hammer and materials. Our SFSP series chipping and crushing machine is your best choice. It mill raw material like tree branch, wood shavings, wood chips, wood logs, cotton stalk, corn stalk, wheat straw etc, with size less than 50mm (diameter). After milled, the output size can reach diameter 3-5 mm, then it is pushed to next process to get dried and pelletized.

3. Ring die wood pellet machine ----Drying process – Rotary Dryer

After crushing process, the wood and biomass material need to be well conditioned on moisture before pelletizing. The best moisture content to pelletizing is about 14-16%. Our rotary dryer is made up of burning stove and main rotary dryer which is high efficiency in drying the wood and biomass material. It use steam to heat air and contact material to remove certain degree of moisture. It is very important for wood pellet plant to using moisture detector which will determine the most suitable moisture before pelletizing.

4. Ring die wood pellet machine ---Pelletizing process - Wood pellet mill

Ring Die wood pellet machine is the heart of the pellet machine production line. The Pellet machine is widely used in compacting of wood, straw, other biomass sources into pellet. Capacity ranges from 1T to 10T per hour. Our MZLH series pellet mill adopt SKF bearings from Sweden and NSK bearings from Japan, the motors in the wood pellet is from Siemens, high quality components make the pellet mill more efficient and durable.

| Model | Power | Pellet size | Inch | Production | Dimension | Weight |

| (mm) | (kw) | (mm) | (t/h) | (mm) | (t) | |

| YFK450 | 55 | Φ4-Φ12 | 450 | 0.3-1 | 2200x900x1600 | 3 |

| YFK550 | 75 | Φ4-Φ12 | 550 | 0.7-1 | 2300x1000x1780 | 4.8 |

| YFK560 | 90 | Φ4-Φ12 | 560 | 1-1.5 | 2600x1300x2300 | 5.8 |

| YFK580 | 160 | Φ4-Φ12 | 580 | 1.5-2 | 2900x1300x2400 | 6.5 |

| YFK680 | 160 | Φ4-Φ12 | 680 | 2-2.5 | 3200x1400x2400 | 8.5 |

| YFK850 | 220 | Φ4-Φ12 | 850 | 2-3 | 3750x1650x3250 | 12.6 |

| YFK880 | 315 | Φ4-Φ12 | 880 | 3-4 | 4300x1900x3600 | 14.5 |

5. Ring die wood pellet machine----Cooling process - Pellet cooling machine

After the pelletizing process, the temperature of the wood pellet is about 60-80 degrees Celsius, and the moisture content of the wood pellets is about 15%. A cooler must then be used to reduce the moisture content of the wood pellet to about 3-4%, thereby making the wood pellet easy to store. However, some customers said that the local climate is very humidity, they want to cool the wood pellets with moisture 7-8%. It is no problem, our new stabilizer combined cooler can do it well.

6. Ring die wood pellet machine ----Packing process - Pellet packing machine

After cooling process, the wood pellets will not directly enter into the fuel process, avoiding the wood pellet affected with damp, the packing process is very necessary. The packing process is effectively handled by our Semi-Auto Packing Machine.

Please kindly note: Not all these processes are necessary for you. These are common processes for your reference. we will customize the complete solution as per your raw materials condition and your request for capacity.

Machine delivery and customer's running site

Our factory

Our Service

As a professional and experienced supplier of turn-key pellet plant projects in China, we have the

ability to provide full services for customers:

1. Complete project design

2. Equipment manufacture and project engineering

3. Machinery delivery service to most of the locations in the world

4. Plant installation and commissioning service

5. Staff training and project managements

6. Spare parts supply and lifelong consultation service

7. Possible financial and banking services for some projects