Эпоксидная полиуретановая машина для смешивания силиконовой

- Категория: Оборудование для производства электроники >>>

- Поставщик: Guangzhou,Zhengqi,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.7 $* | 0.74 $* |

| Aug-16-2025 | 0.88 $* | 0.38 $* |

| Jul-16-2025 | 0.1 $* | 0.85 $* |

| Jun-16-2025 | 0.87 $* | 0.72 $* |

| May-16-2025 | 0.64 $* | 0.56 $* |

| Apr-16-2025 | 0.23 $* | 0.36 $* |

| Mar-16-2025 | 0.31 $* | 0.1 $* |

| Feb-16-2025 | 0.22 $* | 0.59 $* |

| Jan-16-2025 | 0.76 $* | 0.20 $* |

Характеристики

Epoxy PU silicone resin mixing machine dispensing machine

Whatsapp, wechat and Tel are available to contact me for quick response

Name:Mr. Jason Huang

Tel/Wechat/Whatsapp: +86 15626250060

Epoxy PU silicone resin mixing machine dispensing machine

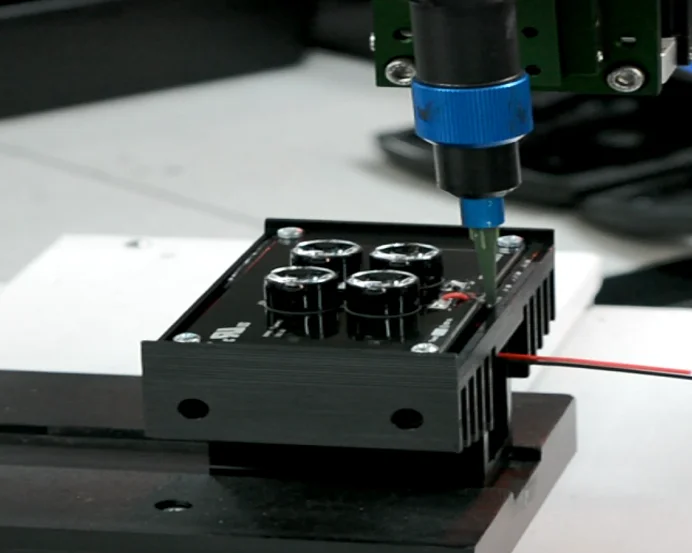

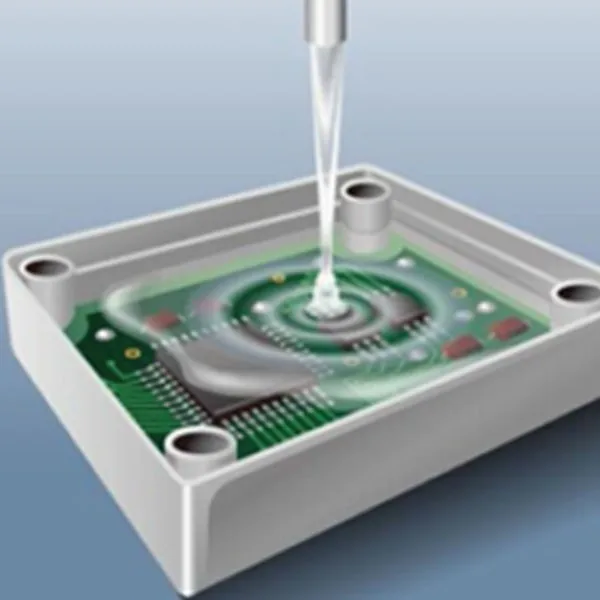

PJL-1200 system accurately meters, mixes and dispenses two-component medium to low-viscosity materials for potting, gasketing, sealing, encapsulation and syringe filling. For variable ratio dispensing, the system handles ratios from 1:1 to 10:1.

The system is composed of material tank, metering pump, metering motor, material pipe, two component valve, motor for dynamic stirring and mixing tube. Two kinds of glue are separated before they mix in mixing tube, so the glue will not cure in devices. Glue valve is with vacuum function to keep thin fluid from dripping. Other optional functions include:

Tank stirring function;

Tank defoaming function;

Thermostat heating function on Tank, pipe, and pump;

| \t | |||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

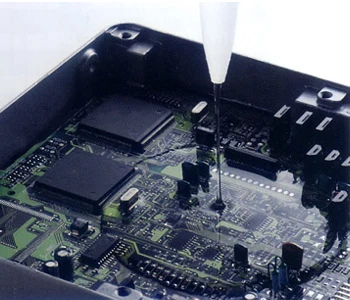

Applications

1. Electrical Products: Electronic parts, integrated circuits, circuit board solder paste, fixed and dust and moisture protection, LCD liquid crystal screen, speakers, headphone, audio, LED, optical lens, SMD transformers, relays.

2. Communication Products: Keypad, mobile phone casing bonding, radio, telephone, Computers, MP4, electronic toys, chassis bonding, switches, connectors, plug cable.

Machine features:

1. Automatic metering and mixing, touch screen PLC control system, English operation interface allow easy to set parameters;

2. Big LCD screen displays various processing data;

3. Easy programming of dots, stripes, arcs, compound arcs and patterns on different planes;

4. Gluing speed and timing can be set;

5. CAD file can be imported and turned to be dispensing patterns, and downloaded via USB; (optional function)

6. Mixing ratio 1:1-1:10 and gluing volume can be set and adjusted as per actual need. Dynamic mixing ensure two component glue to be mixed to a fully homogeneous consistency;

7. Metering, mixing and gluing simultaneously;

8. Two tanks keep A glue and B glue separately;

9. Liquid level sensor, alarm function;

10. Tank stirring and vacuum defoaming function optional;

11. Auto cleaning; The cleaning mode can be manually or automatically, manual mode just remove the mixing tube then soak into cleaning agent, after 10 min take out and clean with compressed air, Automatic mode only need to operate the cleaning switch on touch screen within 1 minute to complete;

12. Glue tank/metering pump/glue pipe heating function (optional);

13. Vacuum control keeps thin fluids from dripping;

14. Unique control system which will not influenced by air pressure factor, ensures optimal dispensing performance;

Panasonic PLC.

High precision Panasonic PLC ensure high stably performance and precisely AB glue output quantity

Dynamic mixing.

High speed mixing motor, mixing glue well. According to glue features, static mixing is available

Vacuum tank with stirring motor.

With defoaming function and mixing motor, no bubbles in glue, pre-heating is available for selection

Tank with liquid sensor.

Both AB tank with high level and low level liquid sensor, when the glue is not enough or the machine is abnormal, the machine will show the warning message. Humanized engineering design, avoid the serious damages. There's a professional sealing ring to make sure the glue tank in vacuum status. To avoid the glue to be crystallization or curved.

Vacuum tank.

vacuum tank with auto glue filling function

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

| \t | |

| \t | \t |

| \t | \t |

| \t | \t |

PGB-200

Small automatic Glue dispensing machine with working area: L480mm*W480mm*H80mm

QPD-300

Glue dispenser for LED bulbs with 3 heads

SZD-700

One component glue dispensing machine with working area: L700mm*W700mm*H80mm

PJL-1500

Automatic glue mixing machine, manual glue dispenser

PGB-1200

automatic Glue dispensing machine with working area: L1200mm*W1200mm*H80mm

PJL-1200

Automatic glue mixing machine, manual glue dispenser, with long pipe