Высококачественная криогенная жидкость СПГ кислород азот аргоновый криогенный резервуар для хранения

- Категория: Chemical Storage Equipment >>>

- Поставщик: Jianyang,Greenfir,New,Energy,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 11900.30 $* | 12495.29 $* |

| Aug-16-2025 | 11800.70 $* | 12390.38 $* |

| Jul-16-2025 | 9900.17 $* | 10395.9 $* |

| Jun-16-2025 | 11600.74 $* | 12180.44 $* |

| May-16-2025 | 10100.63 $* | 10605.19 $* |

| Apr-16-2025 | 11400.12 $* | 11970.72 $* |

| Mar-16-2025 | 11300.34 $* | 11865.0 $* |

| Feb-16-2025 | 11200.79 $* | 11760.9 $* |

| Jan-16-2025 | 11100.88 $* | 11655.28 $* |

Характеристики

Related Products

Product Paramenters

Product Details

Product Description:

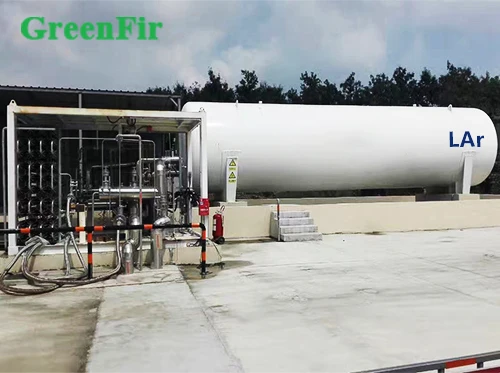

CRYOGENIC TANKS

Storage tank is for liquefied gas under pressure, at cryogenic temperatures, for products, such as LNG, N2, O2, Ar, CO2.

They consist of two vessels, one inside the other, with robust thermal insulation in the chamber between them. They are built in both a vertical (with legs or skirting ) and horizontal version(with support cradles and anchoring to the ground).

Design

According to ASME, GB150, GB18442 standards.

Inner pressure vessel

A vessel usually made of austenitic stainless steel or other materials that have favorable strength characteristics when exposed to cryogenic temperatures.

Insulation

Heat insulation is provided by a filling in the chamber between the two vessels using insulating material and a high vacuum. It includes absorbent material for greater vacuum stability. The effective thermal insulation minimizes product losses and enables lengthy storage times of low temperature liquefied gases.

Outer vessel

A vessel made of carbon steel or stainless steel. Under normal operating conditions, this vessel retains the insulation around the inner pressure vessel, and can also maintain a vacuum around the inner vessel. Typically, the outer vessel is not exposed to cryogenic temperature.

Application Fields:

These tanks can be widely used in various industries, such as machine building, gas, chemical engineering, synthetic fiber, medical, food industry, mining, electronic, metallurgyand military engineering, etc.

Product Features:

1. Inner vessel: The austenitic stainless steel material which is suitable for cryogenic working condition is adopted. The structure design is optimized and reasonable.

2. Inner pipeline: The flexible design and inspection is to ensure the quality and appearance of the products. Unique energy-saving pipeline design can ensure the safe use of the product in any medium.

3. Outer vessel: Using Q345R materials, it is equipped with special stainless steel transport support, and lateral lifting lugs to transport easily and reduce the installation cost greatly.

4. Vacuum insulation: We use unique leak detection process, high quality pearl sand, high vacuum multilayer insulation, special sand irrigation process, so that our products have excellent vacuum insulation performance.

5. Valve piping system:

①The structure is compact. The pipe length is less than that of the conventional tank, and the heat loss of the external pipe is effectively reduced.

②The combination valve reduces the number of welded joints to improve safety and reliability, and reduce maintenance costs.

③ With all stainless steel piping design, it provides reliable performance for long service.

6. Safety: The storage tank is equipped with a double safety discharge system with two safety valves and two bursting discs, which enables one of them to be isolated while the other is maintained or under repair.

7. Cleaning standards: All parts in contact with the medium shall be cleaned in strict accordance with the requirements for storing liquid oxygen.

8. Outer surface: It is shot blasted and protected with two layers of coating: high anti-corrosion primer followed by a reflective white polyurethane epoxy topcoat.

Quality Promise

1.Product technology level:

They are designed, manufactured, inspected, and accepted in accordance with advanced European and American national standards and specifications, and meet the requirements of Chinese national standards and specifications. Products with high requirements for the reliability and safety of gasifiers.

They are designed, manufactured, inspected, and accepted in accordance with advanced European and American national standards and specifications, and meet the requirements of Chinese national standards and specifications. Products with high requirements for the reliability and safety of gasifiers.

2.Overall product quality assurance:

Ensure that the product design, manufacturing, inspection, and acceptance processes (design → procurement → component manufacturing and welding → assembly → inspection and testing → non-destructive testing → final assembly and packaging before delivery) are effectively implemented in strict accordance with the requirements of the ISO9001: 2008 quality management system Control and form records, the buyer can select control points to the site for inspection and confirmation as required, and the factory will provide the necessary working conditions.

Quality guarantee period is 12 months for normal equipment operation

Ensure that the product design, manufacturing, inspection, and acceptance processes (design → procurement → component manufacturing and welding → assembly → inspection and testing → non-destructive testing → final assembly and packaging before delivery) are effectively implemented in strict accordance with the requirements of the ISO9001: 2008 quality management system Control and form records, the buyer can select control points to the site for inspection and confirmation as required, and the factory will provide the necessary working conditions.

Quality guarantee period is 12 months for normal equipment operation

Security Settings

1.The storage tank is equipped with a combined safety device (safety valve) to prevent the equipment from operating under pressure.

2.Each storage tank is also equipped with an auxiliary rupture disk device to further prevent the equipment from overpressure. This rupture disk will completely burst when the safety valve fails and the pressure exceeds the pressure of the

rupture disk to release the internal tank pressure.

rupture disk to release the internal tank pressure.