От 10 до 12 лет/ч автоматический сухая Ступка прибор миксер керамический плиточный клей машина по

- Категория: Машины для сухой смеси >>>

- Поставщик: Zhengzhou,MG,Industrial,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 67116.65 $* | 70472.14 $* |

| Aug-15-2025 | 66552.79 $* | 69880.55 $* |

| Jul-15-2025 | 55836.1 $* | 58628.33 $* |

| Jun-15-2025 | 65424.87 $* | 68695.73 $* |

| May-15-2025 | 56964.15 $* | 59812.17 $* |

| Apr-15-2025 | 64296.71 $* | 67511.62 $* |

| Mar-15-2025 | 63732.10 $* | 66919.61 $* |

| Feb-15-2025 | 63168.88 $* | 66326.39 $* |

| Jan-15-2025 | 62604.0 $* | 65734.16 $* |

Характеристики

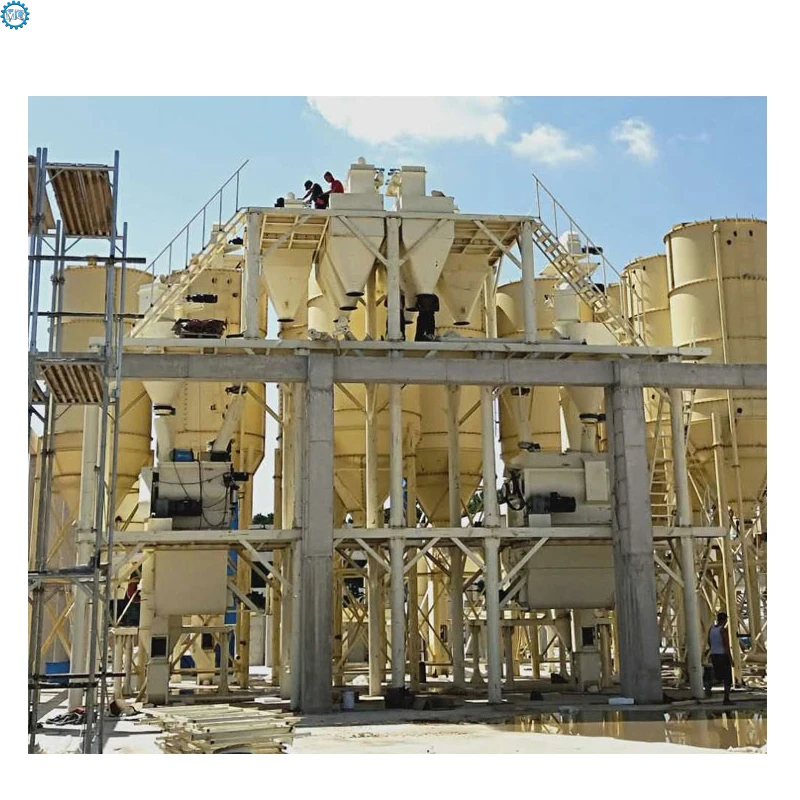

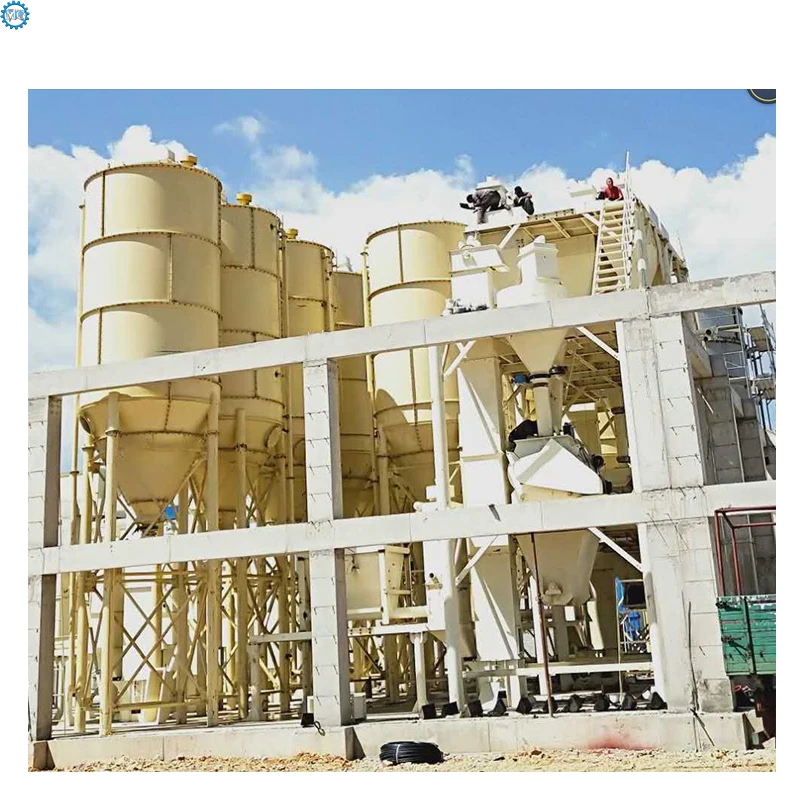

10-12t/h Automatic dry mortar mixer machine ceramic tile adhesive mortar manufacturing machine

Dry mortar production line is also called premixed mortar production line, which made in the factory by precise batching and uniform mixing.

Dry mix mortar Production line has advantages of consistent quality, controlled automatically, saving time and labor costs. By adding different chemical additives, it has fine properties of bond, thermal and acoustic insulation, crack-resistance, work ability, water-retention, wear-proof, anti-corrosion, etc.

MGDM-3.7 Automatic dry mortar production line is used for producing dry mortar with capacity of 10-12t/h, Which is based on the latest design concept in Europe, this production adopts the advanced computer auto-control system, whose production capacity can reach 30-36 thousand tons per year depend on the system configuration.

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

Storage silos and bucket elevator

Store raw materials such as cement, fly ash, thickened powder, quartz powder or yellow sand. Our company's raw material warehouse cone parts pneumatic break arch device, can effectively prevent cement, fly ash knot arch. Ensure smooth measurement of spiral ingredients..

Screw conveyor

Screw conveyor is a kind of continuous conveying equipment. The screw conveyor of our company has the characteristics of simple structure, small cross-sectional area, convenient closing and conveying, and easy operation.

Weighting hopper

Accurate weighing according to recipe requirements, small error, self-measurement error and repair, high precision.

Pre-mix hopper

It used to store one batch material where various formulation materials and additives are gathered together at a certain ratio by other equipment, is prepared for the next step of mixing.

High effciency Twin-shift agravic mixer

High mixing speed, high uniformity, less power consumption. Materials with large differences in physical properties such as specific gravity, particle size, and shape do not easily segregate when mixed in the mixer.

Finished product line

To store the finished material and prepare for the packing work, the ribbon mixer is to protect the finished material from segregation during the second falling.

Automatic weighting and packing machine

The use of computerized metering devices provides accurate weighing, stable performance and simple operation. And equipped with dust mouth, truly environmentally friendly production.

Impulse dust collector

Bag pulse dust removal and centrifugal cyclone dust removal, dust removal effect is good, fan, cloth cylinder and filter combination as a whole, can shorten the wind network, simplify the process, reduce equipment investment.

1.Main parts will be wrapped with bubble plastic film and put into the wooden box to keep off the rain and sea water.

2.Spare parts will be wrapped with bubble plastic film to keep off the rain and sea water.

3.All the parts will be fastened with steel rope.

Zhengzhou MG Industrial Co,.Ltd focuses on the design manufacture of dry mortar production line and sand dryer for 17 years. We provide turnkey project of dry mortar plant from working site planning to dry mortar machines, installation and training, good after-sales services, technical support and so on.

Under principle "CUSTOMER FIRST"and"TEGRITY FIRST", MG people provide a reasonable and practical plan and first class products as well as excellent After-sale Service according to each customer's requirement. Generally speaking, over 75% of our customers or their friends will repurchase our products in a year.

Thanks to our high quality products and outstanding customers service, MG has earned a high reputation in marketing and gained countless customers from Russia, the United Arab Emirates, Malaysia, Brazil, Chile, Morocco and other 90 countries.

With the commitment of customer satisfaction ,we are expecting to widen and deepen the cooperation and communication with all friends all over the world.

1) Unpon got your inquiry, We will reply to you in 24 hours.

2) Assist clients to prepare for the first construction scheme and supply foundation drawing.

3) Oversea installation and provide technical exchange, train client to operate the machine.

4) Supply spare and accessory parts at favorable price for long-term.

5) Spare part are original, authentic, good quality, can be avaible from stock, and sent to client, immediately by DHL, EMS, Fedex, and by air, gurantee client to receive it in shortest time. Strict site quality inspection system:

Installation captain inpection: Evaluate the installation level of dry mix mortar production line, Spot QA engineer inspection: Inspect the whole in installation process and key components.

Service engineer inspection: Inspect the debugging and running condition of whole production line.

1, How about the investment of this project?

A: Our engineer can design the dry mortar mixing equipment as your requirement and your budget, different dry mortar mixing equipment investment are difference.

Low capacity low cost, we will provide you cost effective solutions as your requirement.

2, What's the difference between full automatic dry mortar mixing equipment and Semi-automatic dry mortar mixing equipment?

A: (1)Semi-automatic dry mortar mixing equipment is cheaper than full automatic dry mortar mixing equipment.

(2) Semi-automatic dry mortar mixing equipment do not need to equip silos while full automatic dry mortar mixing equipment equip material silos.

(3) Semi-automatic dry mortar mixing equipment is manual feeding and automatic weighing and packaging, Full automatic dry mortar mixing equipment is automatic feeding and automatic weighing and packaging.

3, How many person required to operate this dry mortar mixing equipment?

A: Usually 2-4 workers are enogh to operate this dry mortar mixing equipment.

4, What equipment and services you can provide?

A: We can provide you turnkey solution of dry mortar mixing equipment from working site planning to dry mortar machines, transportation, installation and training, formula of dry mortars, after-sales services, life time technical support etc.

Contact us freely if you need any supports!!!