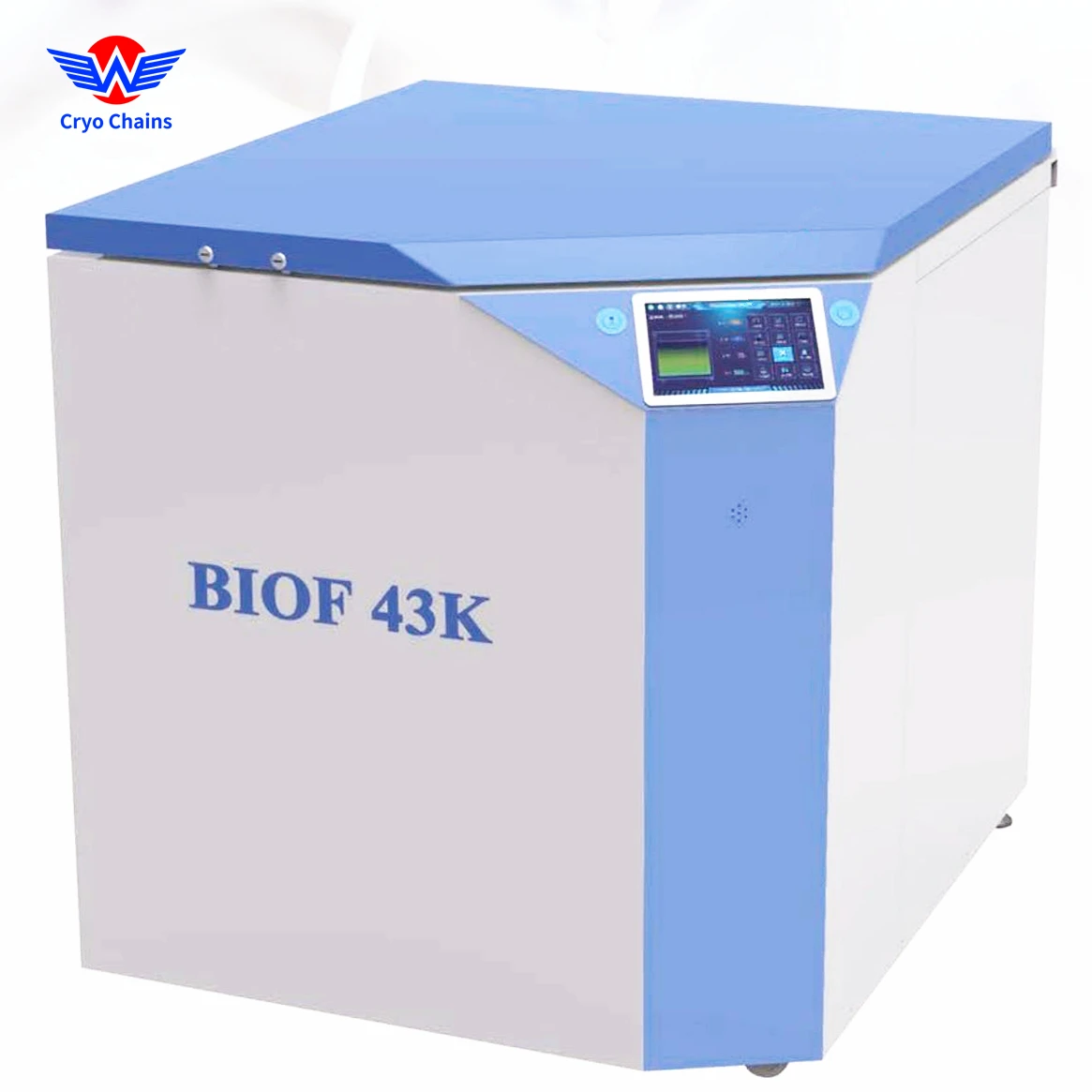

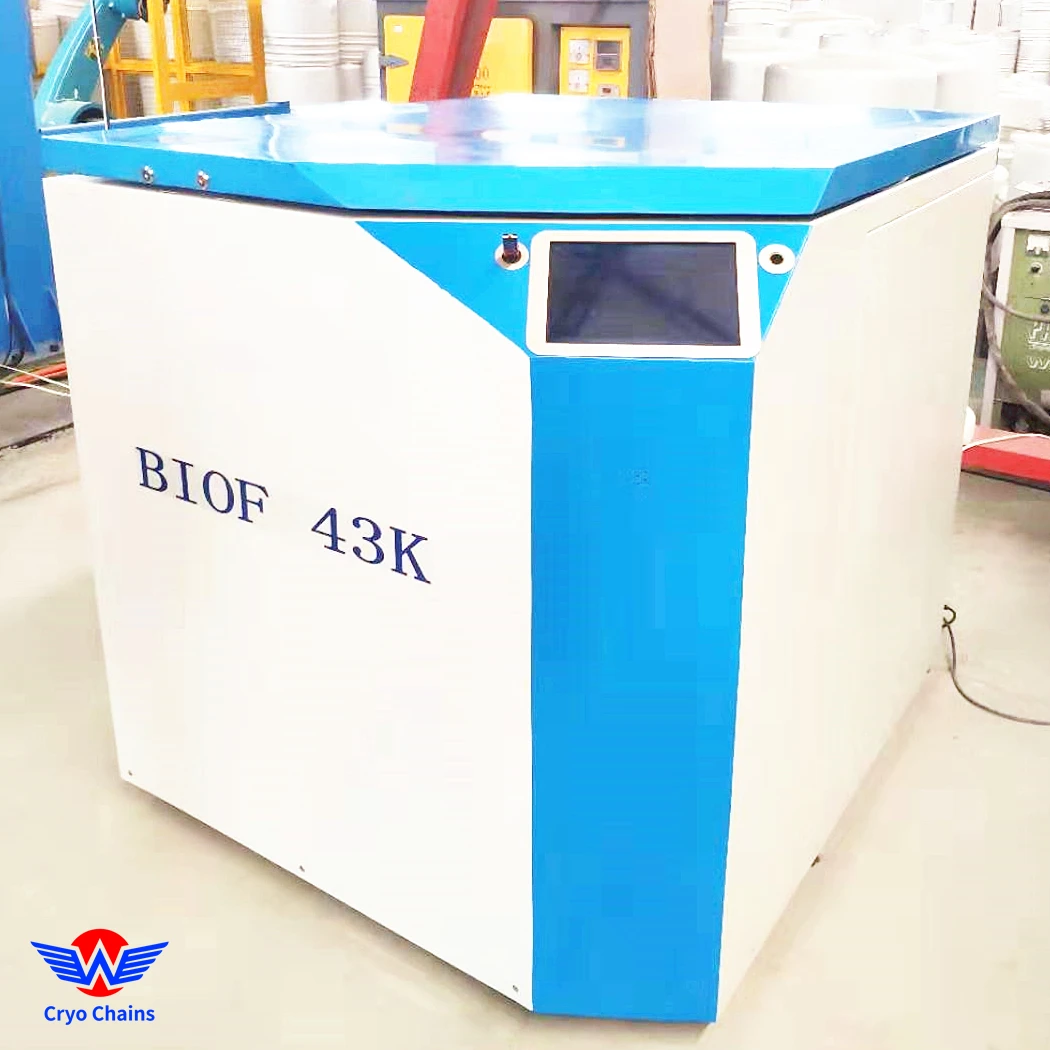

550 литров жидкого азота морозильная камера Biobank ультра низкая температура миниатюрная криогенная для кордной

- Категория: Freezing Equipment >>>

- Поставщик: WOBO,Industrial,Group,Corp.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.22 $* | 0.70 $* |

| Aug-19-2025 | 0.38 $* | 0.14 $* |

| Jul-19-2025 | 0.90 $* | 0.13 $* |

| Jun-19-2025 | 0.87 $* | 0.97 $* |

| May-19-2025 | 0.59 $* | 0.11 $* |

| Apr-19-2025 | 0.6 $* | 0.59 $* |

| Mar-19-2025 | 0.83 $* | 0.76 $* |

| Feb-19-2025 | 0.8 $* | 0.13 $* |

| Jan-19-2025 | 0.69 $* | 0.96 $* |

Характеристики

550 Liters Liquid Nitrogen Biobank Freezer Ultra Low Temp Miniature Cryogenic Freezer For Cord Blood

Product Description

Parameters:

Wooden case packaging. Mode of transport: by sea or by air or by train.

Our Services

OEM, ODM. We can provide a good after-sales service.

Company Information

We are focus on cryogenics for over 10 years, and can provide professional one-stop service for cryogenic vessels, equipment, and solutions.

We are good at non-standard customization service and developing new products on various cryogenic applications.

Cryo Chains is a high and new tech company, which is specialized in R&D, OEM and selling cryogenic container, cryogenic freezing equipment, and cryogenic solutions.

Cryo Chains has always been upholding the corporate concept that “the company should seek supreme quality, advanced technology, sincere service and innovative development”. We have a technical team of professional technical personnel with experience of about many years in R&D and manufacturing of various types of cryogenic liquid storage transportation, cryogenic freezing equipment.

We have accumulated rich experience in acquiring and keeping vacuum, multi-layer insulation, cryogenic freezing equipment and biological product cryopreservation, cryogenic intelligent electronic control system, and so forth. We have successful experience of several major cryogenic engineering implementations, we have established technical cooperation with various food plants, higher medical institutes and scientific research institutions.

Our business covers stem cell bank, blood bank, hospital, biological engineering, animal husbandry, higher institute, research institution, machinery, petrifaction, semi-conductor, aerospace, superconductor, industrial gas and liquid, metallurgy, frozen food preservation, and so on, and could provide mature project designs.

Our products have passed the test of national cryogenic liquid container testing center; meanwhile we get the CE certificate. The company strictly follows ISO 9001 quality control procedures to ensure its product quality and 100% qualified product rate. In the meanwhile, after-sale service system of quick response is established to make sure that users can safely use its products. Now our products have been sold to over 45 countries in the world and earn very good reputation.

FAQ

Q: What are the Product Advantages?

A: Big storage capacity

Compared with similar products, our products need less space and could store more samples; save space and also reduce the cost;

Excellent temperature uniformity

Vacuum insulated stainless steel structure, high vacuum coverage to ensure excellent insulation properties;

Stable open cover temperature

Innovative lid and excellent small neck openings design can greatly reduce the liquid nitrogen evaporation rate.Even keep the lid open for a long time, the temperature inside the tank can still be very stable; temperature could be not higher than -150 ℃with in 48 hours;

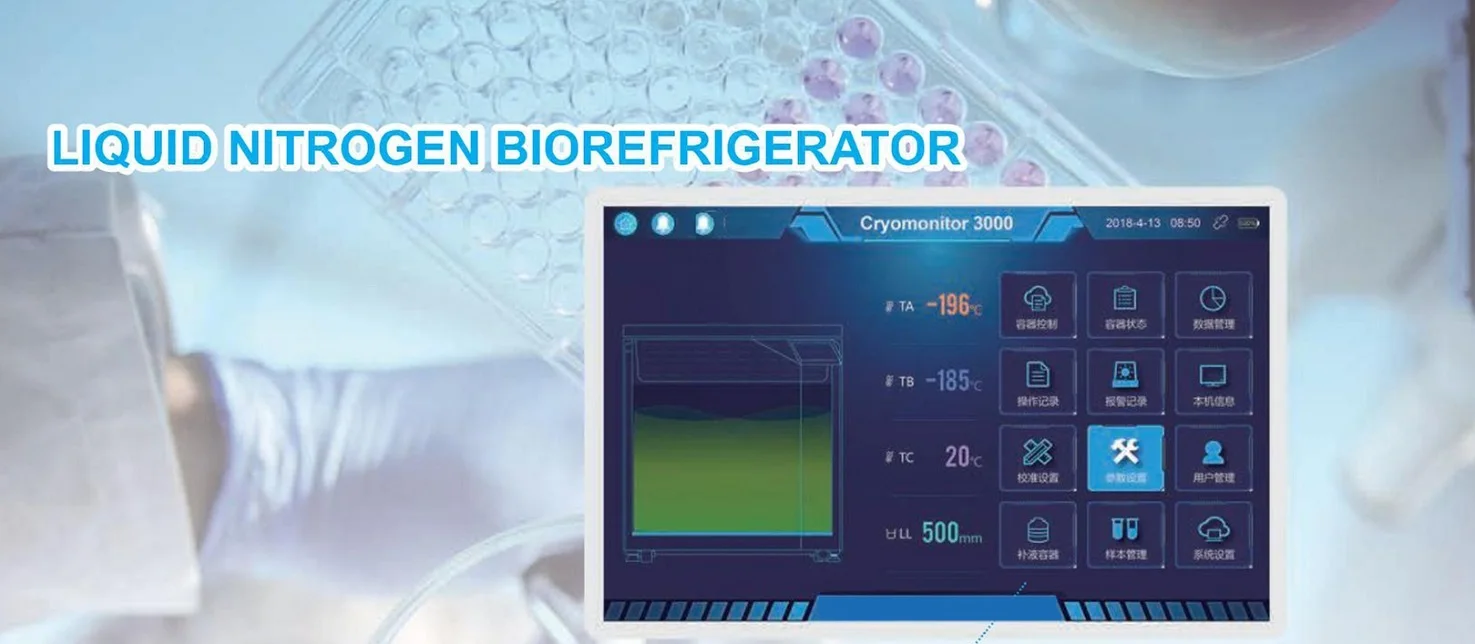

Advanced temperature monitoring system

Microprocessor-based control system and the vertical double platinum resistance temperature probe can display realtime temperature, accuracy of ±1 ℃. The user can set their own alarm temperature value, with alarm mute option;

Automatic filling liquid nitrogen and liquid level monitoring system

Based on the differential pressure sensor, level monitoring system could display real-time liquid level, to ensure that the liquid nitrogen automatic filling process safe and reliable. 10-inchLCD touch screen display: temperature of the top, bottom temperature, liquid level, and operating status etc.

Hot gas bypass

The hot gas bypass can remove nitrogen which is at indoor temperature before the liquid nitrogen is filled, to ensure that only liquid nitrogen is filled into the tank and avoid temperature fluctuations in the liquid nitrogen tank during the filling process. It would make sure the safety of the sample and also reduce the additional Liquid nitrogen consumption.

A number of human design

Stainless steel auxiliary table, can be used for temporary placement for the racks to speed up the sample picking and placing; folding steps reduce the height of the operation platform; spare opening on the internal tray for easy to find inadvertently dropped samples.

Zero Greenhouse Gases

Because LN2 storage depends on the cooling power of naturally souced nitrogen gas, there are no halogenated hydrocarbon refrigerants used and no greenhouse gas concerns.