Высокоскоростная полностью автоматическая термоусадочная этикетировочная машина для круглых

- Категория: Машины для этикеток >>>

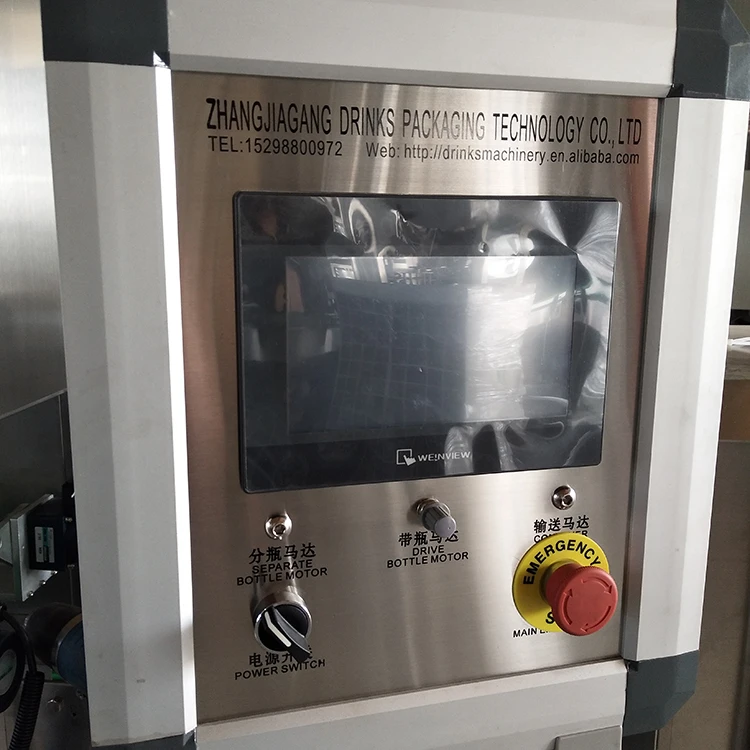

- Поставщик: Zhangjiagang,Drinks,Packaging,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-20-2025 | 1017231.9 $* | 1037576.17 $* |

| Jul-20-2025 | 824998.71 $* | 841498.36 $* |

| Jun-20-2025 | 1001211.59 $* | 1021235.26 $* |

| May-20-2025 | 993202.50 $* | 1013066.19 $* |

| Apr-20-2025 | 792959.70 $* | 808818.14 $* |

| Mar-20-2025 | 977182.56 $* | 996726.82 $* |

| Feb-20-2025 | 969172.32 $* | 988555.12 $* |

| Jan-20-2025 | 961163.87 $* | 980386.78 $* |

Характеристики

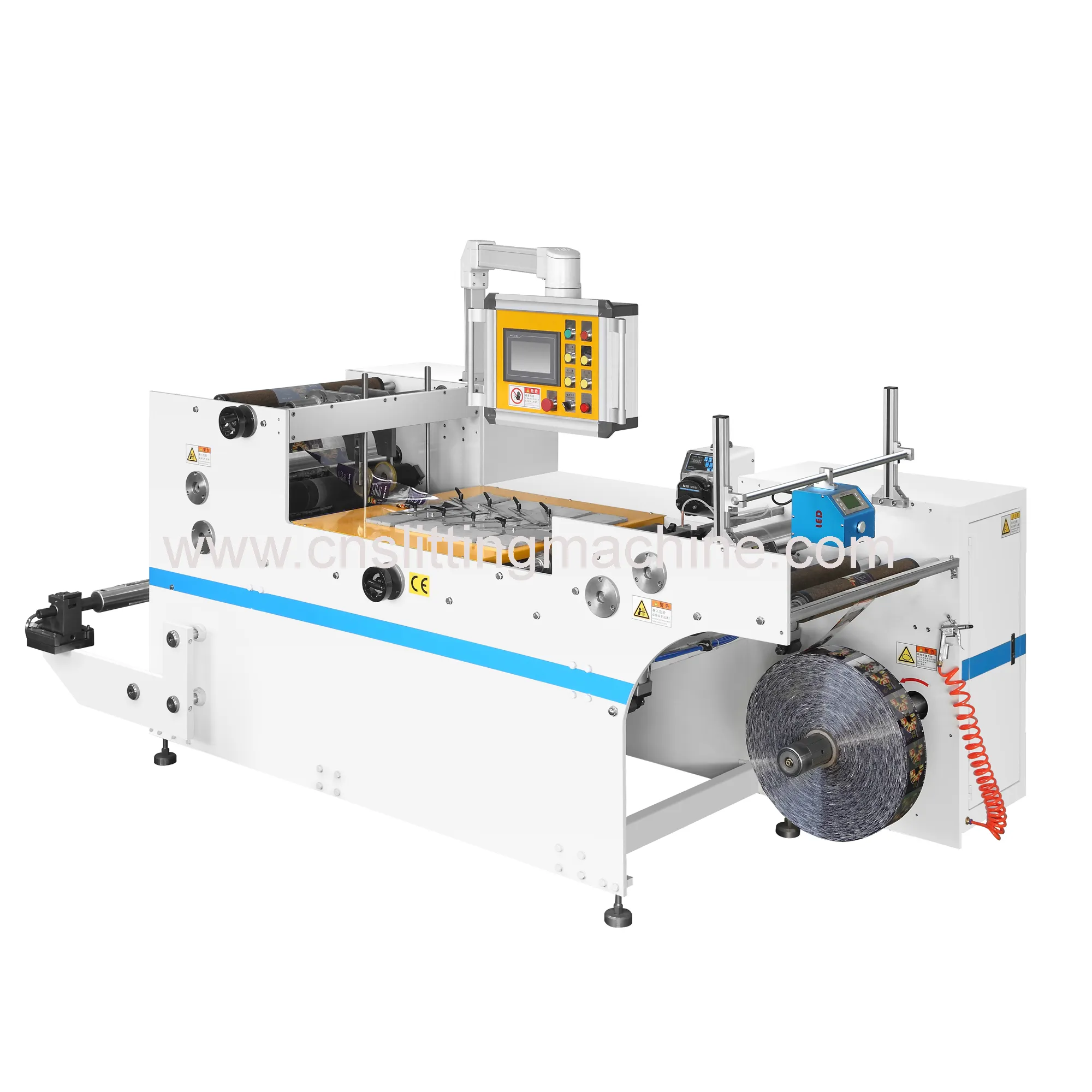

High Speed Full Automatic PVC Sleeve Shrink Labeling Machine For Round Bottles

Shrink label sleeving machine adopts PLC programmable controller, imported servo motor, servo driver, frequency converter and transducer; besides, it adopts the positioning module to ensure the casting.label precise,rapid and stable. It not only has a highly precise position for casting label, but also can withstand the perfect shape of the bottle after shrinkage.

Main performance parameter: | ||||||

Production capacity : | 2000-9000 bottles/hour | |||||

Input power : | 1.3kw | |||||

Input voltage : | 220V AC | |||||

Size of host machine (L*W*H) : | 2000*850*1900mm | |||||

Weight : | 480kg | |||||

Applicable diameter of bottle body : | Φ28 mm-Φ100 mm | |||||

plicable length of label : | 30 mm-220 mm | |||||

Applicable thickness of label: | 0.03 mm-0.13 mm | |||||

Applicable internal diameter of paper tube : | 5" - 10 "free adjustment | |||||

The customer can provide the sample, we customize the equipment according to the sample. | ||||||

1. The new bottle label steam shrinking furnace has greatly improved heat shrinkage efficiency and is suitable for various plastics and glass bottles. For different bottle types and irregular round bottles, square bottles, flat bottles, etc., the furnace is easy to adjust and maintain. Shrinkage is flat.

2. The steam injection method adopts the design of steam distribution package, adjustable steam guiding system, the pipeline is smooth and does not occupy space, and the discharge outlet is divided into three sections on each side. The height of each section, front and rear and air volume can be adjusted separately to reach the maximum. Good shrinkage effect.

3. The low-pressure steam distribution bag is designed with seamless steel pipe, and each connecting pipe uses a stainless steel hose quick connector, which is convenient for disassembly and installation.

4. The whole machine casing is made of stainless steel SUS304, which saves energy and meets food safety standards.

5. The bottom stainless steel water tray is concentrated with condensed water, which can be taken out and the working environment is not affected.

Technical Characters:

1. All-cover type stainless steel host machine:the whole machine is waterproof as well as rustproof.

2. Adjustable cutter head:uniquely cyclotron cut-off, double sided cutting edge with a long service life.

3. Single positioning center guide pillar:a more stable for label delivery.

4. Synchronous bottle divider: a more stable transmission for bottle.

5. Bottom set of label brush:a more precision for casting label.

6. Label-controlling electric-eye shelf:unique combination of tail and electric-eye to improve the precision

for cutting off the membrane materials.

7. Push-button control cabinet:a more humanized operation.

8. Independent feeding material shelf: the position of the material shelf is optional at will.

Q:Will these products be what I want?

A:If not, you can also visit our website and select other products. Our website is:http://drinksmachinery.en.alibaba.com

Automatic bottle unscrambler Mixer Machine Water treatment system

Mineral Water Filling Machine Ink-jet printer Film wrapping machine

5 Gallon Filling Machine Spray sterilization machine Bottle blowing Machine

Transport Port : Shanghai Port.

Transportation: By van ,by train, by plane.

Packaging Details :Machine will be packed by PVC film+ standard wooden case or carton.

Wooden case suitable for long distance ocean shipping.

Q. Are you a trading company or manufacture?

A: We are manufacture ,we have our professional manufacturing teams and technicians.

Q: Do you have technical support?

A: Our company is responsible for installation and debugging of equipment, meanwhile, responsible for the technology and operation training for user operator.

Q: How is your delivery time?

A: Generally speaking, the sample order takes 5-7 days, and it takes 15-25 working days for the bulk order after receiving the payment. The exact delivery time depends on the project project and the number of orders.

Q: How do you make our business long-term and good relationship?

A1. We maintain good quality and competitive prices to ensure our customers benefit;

A2. We respect every customer as our friend, we sincerely do business with them and make friends with them, no matter where they come from. We are partners.

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com