Small scale plastic recycling plant waste pp

- Категория: Recycle Washing Line >>>

- Поставщик: Zhangjiagang,Kooen,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 46410.98 $* | 48731.94 $* |

| Aug-17-2025 | 46020.0 $* | 48321.57 $* |

| Jul-17-2025 | 38610.25 $* | 40541.95 $* |

| Jun-17-2025 | 45240.54 $* | 47502.49 $* |

| May-17-2025 | 39390.60 $* | 41360.26 $* |

| Apr-17-2025 | 44460.12 $* | 46683.39 $* |

| Mar-17-2025 | 44070.42 $* | 46274.54 $* |

| Feb-17-2025 | 43680.99 $* | 45864.68 $* |

| Jan-17-2025 | 43290.99 $* | 45455.0 $* |

Характеристики

Small scale plastic recycling plant waste pp plastic recycling machine plastic recycling

Working Flow:

Belt conveyor * 2 → Crusher * 2 → Screw friction washer* 2 → Floating washer →Screw friction washer →Floating washer →Screw conveyor → High speed friction machine → Screw conveyor → Two direction horizontal separating screw → Squeezer machine* 2 →Storage hopper → Control cabinet

Main Components:

Machine name | Main specification | ||

|

Belt conveyor Control method: frequency control | ||

|

Crusher *2 Motor power: 37/55/90kw Fix knives quantity: 4 pc Moving knives quantity: 10 pc Knife material: SKD-11(from Japan) crushing with water | ||

|

Screw friction washer *2 Motor power: 22kw Rotation speed: 900rpm Diameter: 650mm Main shaft through dynamic balance treatment | ||

|

Floating washer Dimension(L*W): 6000*1800mm Made of SUS304 stainless steel | ||

|

Screw friction washer Motor power: 22kw Rotation speed: 900rpm Diameter: 650mm Main shaft through dynamic balance treatment Made of SUS304 stainless steel | ||

|

Floating washer Dimension(L*W): 6000*1800mm Made of SUS304 stainless steel | ||

|

Screw loader Motor power: 5kw Diameter: 500mm Made of SUS304 stainless steel | ||

|

High speed friction washer Motor power: 22/37/45KW Rotation speed: 1200rpm Main shaft through dynamic balance treatment

| ||

|

Screw loader Motor power: 5kw Diameter: 500mm Made of SUS304 stainless steel | ||

|

Two direction screw conveyor Motor power: 5.5 kw Diameter: 500mm Made of SUS304 stainless steel | ||

|

Squeezer machine Motor power: 75/90/132KW Screw diameter: 250/300/350mm Screw/barrel materials: 38CrMoAl Nitrified, CNC treatment Cutting motor power: 5.5kw Fan blower power: 7.5kw | ||

|

Storage hopper Volume: 3.5m3, made of stainless steel | ||

|

Control cabinet World famous brand

| ||

Advantages:

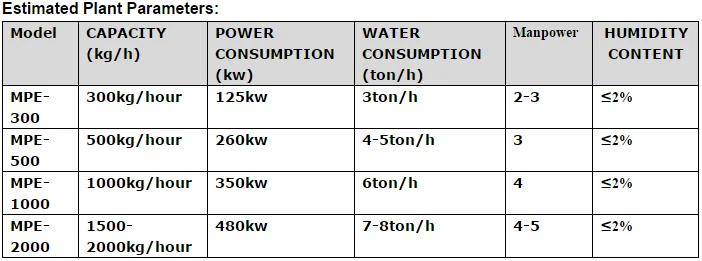

1. Final products has good quality. When process PP PE film bags, final products humidity below 2%.

2. The machine with high efficiency, working stable, large capacity etc.

3. Parts which contact material use SUS304, thickness more than 3mm, ensure long service life time.

4. World famous brand components applied on the production line

5. The whole production line with CE certification, ISO9001 certification .

Related products

KOOEN company more plastic recycling machine for reference

For choosing proper machine and saving your time, please read these bellow guides carefully:

1. What material do you want to process/recycling? PE/PP film? PE/PP rigid plastic flake? PET flake? or other plastic?

2. What capacity (kg/h) do you want?

3. When (Times for delivery) do you want the machine?

4. Other requirements about the plastic film washing and recycling machine you want.

Turnkey project service:

1. we will provide all the machines for the complete production according to customer's requirements.

2. we will provide complete service for factory layout and other information to help customer to build the factory.

3. we will provide good service for machine installation and training, until the customers can run the machines and make stably production.

4. Except one year quality guarantee, we will provide after-sell service for all the life.

5. for long-term cooperation, we always provide good quality, good price and good service to customer.

KOOEN is a leading waste plastic recycling machinery manufacturer in China, dedicated to series waste plastic recycling machine with more than 20 years export experience. If you have related requirement about waste pe pp plastic film /PET bottle crushing washing and recycling machine/linle, please do not hesitate to let me know...

Waste plastic recycling PP PE PET film bags bottle washing line plastic recycling plant cost of plastic recycling machine

Note, If you want to see more information (video) of this plastic recycling production line, please log on our website( www.kooenmachine.com) !