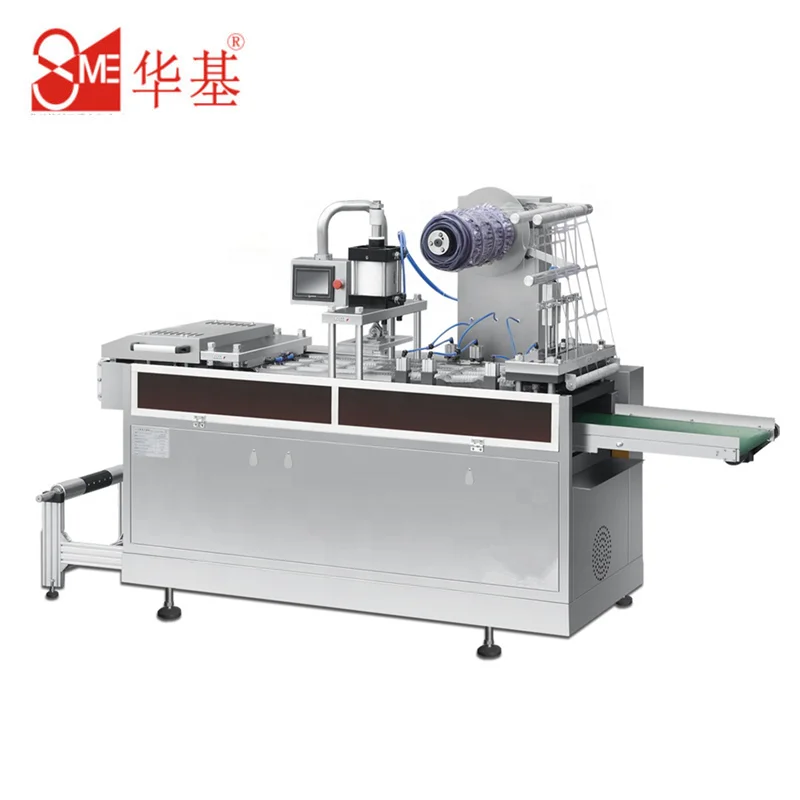

Fully Automatic Plastic Lid Making Machine/Paper Cup Cover

- Категория: Plastic Product Making Machinery >>>

- Поставщик: Superior,Machinery,&,Equipment,Limited

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 23800.76 $* | 24990.0 $* |

| Aug-15-2025 | 23600.22 $* | 24780.84 $* |

| Jul-15-2025 | 19800.55 $* | 20790.53 $* |

| Jun-15-2025 | 23200.85 $* | 24360.94 $* |

| May-15-2025 | 20200.52 $* | 21210.4 $* |

| Apr-15-2025 | 22800.86 $* | 23940.30 $* |

| Mar-15-2025 | 22600.46 $* | 23730.77 $* |

| Feb-15-2025 | 22400.1 $* | 23520.82 $* |

| Jan-15-2025 | 22200.70 $* | 23310.75 $* |

Характеристики

Product introduction

ALM-500 series Auto blow moulding and plastic sucking lids forming machine is developed by our research and development personnal according to packing market requirement. In combination with the advantages of aluminum-plastic blister packing machine and plastic sucking forming machine. this machine is a new type product developed in light of pharmaceutical standard GMP and food standard QS. this machine adopts a fully automatic flow covering blow moulding or plastic suction moulding ,punching and diet cutting as the special properties of products required by the users. It is with advanced technology, safe and simple operation, which will avoid the consumption of labor on the manual punching and containation from the touch with the employeehe. Therefore, the quality requirement is secured during the production.Aligned heating is employed by the equipment, and it enjoys low power consumption, small covering of land.

Preformance Features

1. Speed reducer, main-rotating connection, main shaft are on line(to derease driving error) for mechanical transmission.

2. Sensor controls are adpoted in pneumatics system. PLC control makes the whole machine run smoothly, keeps synchronous stability during the products are to be packed in multi-labor, long-distance.

3. Main motor variable frequently speed regulating, the travel adjustble at will, simple and convenient to change the mould, camtraction, stable running.

4. Positive pressure formation in the equipment(Puffing forming)

Model | ALM-500C |

Suitable Material | PS/HIPS/PVC/PET |

Journey Range | 30-120mm |

Max Forimng Area | 470×290mm |

Max Forimng Depth | 47mm |

Max.material width | 500mm |

Stoke | 60-300mm |

Mold cooling | 60L/H tap water/recycle water |

The Power of Heater | 1.5KW*2pcs |

Motor Power | 2.2KW |

Total Power | 11.5KW |

Required Sheet Width | 500mm |

Material Thickness | 0.15~0.6*500mm Rolls 70-76mm |

Required Sheet Thickness | 0.15-0.5mm |

Air Pressure | 0.5MPa |

Air Consumption | 0.6-0.8m3/min |

Water Consumption(recycle) | 60 liters/hr |

Punching Frequency | 15-45 Punch/min |

Total Power of Electric Source | 380V 50HZ 3 phase |

Weight | 2400Kg |

Dimensions | 3500×1000×1800mm |

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

6) The shape of products can be customized by customers.

7) Only need to changing the mold can product Lid/Cover/Tray/Container/Box/Plate, etc.

Sample:

Pls kindly send an inquiry to us,in order to get more product detail & newest price.

Question: How can install the machine and operate it?

1.Our machine is easy to install and convenient to operate.

2.We will send you English version manual, videos, photos to let you know how to do it. Meanwhile we also support free online service for you.

3.Just tell us what you need and what problems happen.

4.We will give you the best solutions within 24hrs.

5.Also we can provide engineer overseas service.

Question: How can you ensure the machine quality?

1.The accessories in the machine are imported from Japan, German, Korea and so on.

2.Our goal is win the customer with best quality.

3.All our workers in factory has more than 5 years experiences in this field.

4.And we will test and check the machine again before shipped.

Question: How to order the machine?

1.Corfirm the machine model and other terms by E-mail/ wechat;

2.We accept payment T/T or L/C terms;

3.Delivery by sea;

4.Installation and operation;

Question: How do we pack the machine?

1.Small machine will be packed with wooden case(esport standard, no need additional fumigation)

2.Fragile parts wil be seperately packed with cushion packing material or in cartons;

3.Large machine will be packed with cushion packing material;

Question: How about the installation and trainning?

1.Most machines will be packed with no take apart, it comes to be a complete machine; You can start the operation with connect power and air compresor.

2.For other cases, videos and manul book will be sent for the installation.

3.Parameters will be set up before delivery. Customer will do little adjustment.

4.Overseas service is available

Question: How about the after sale service

1.All our machines is one year warranty, spare parts will be freely provided within 12 months

2.We have all spare parts in stocks

3.12-24 hours Online service by Email or Video Online for basic setup and repairs

4.Engineer overseas service is available.

Question: Do you have the customized service?

1.The voltage of the machine can be 110/220/380/440V, 50/60 Hz. Please confirm us the voltage details when place an order

2.The color of the machine can be customized, please send us the color sample

3.The function of the machine can be customized, such as: PLC control, auto-turntable, robotic, etc