Индукционная плавильная печь 20 тонн 1400c для

- Категория: Промышленные печи >>>

- Поставщик: Shanghai,Electric,Heavy,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 11900.6 $* | 12495.17 $* |

| Aug-20-2025 | 11800.91 $* | 12390.12 $* |

| Jul-20-2025 | 9900.21 $* | 10395.99 $* |

| Jun-20-2025 | 11600.71 $* | 12180.75 $* |

| May-20-2025 | 10100.0 $* | 10605.21 $* |

| Apr-20-2025 | 11400.26 $* | 11970.61 $* |

| Mar-20-2025 | 11300.64 $* | 11865.50 $* |

| Feb-20-2025 | 11200.32 $* | 11760.45 $* |

| Jan-20-2025 | 11100.72 $* | 11655.26 $* |

Характеристики

nduction Furnace Product Description:

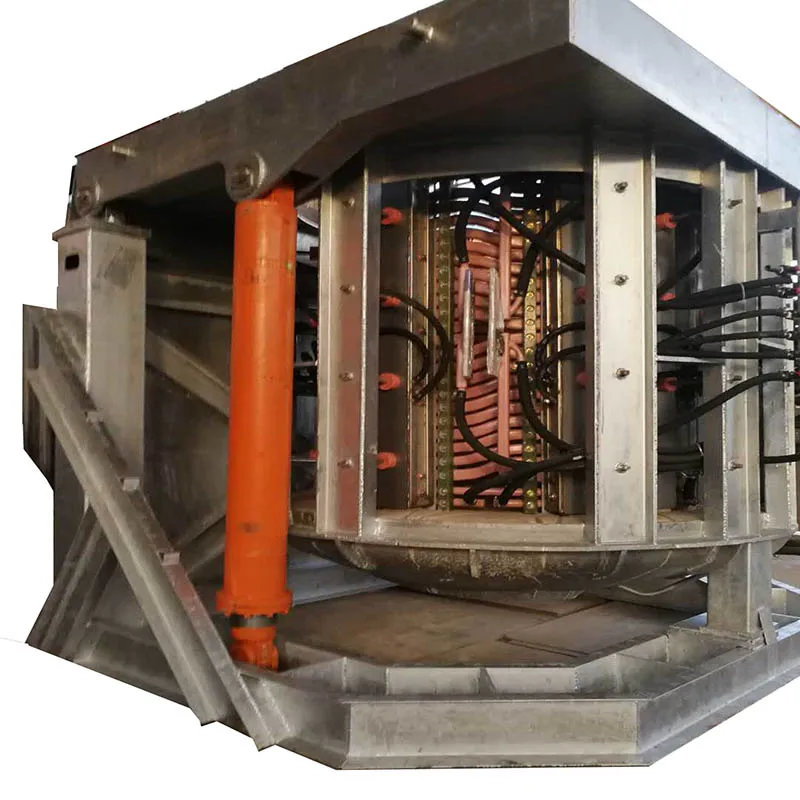

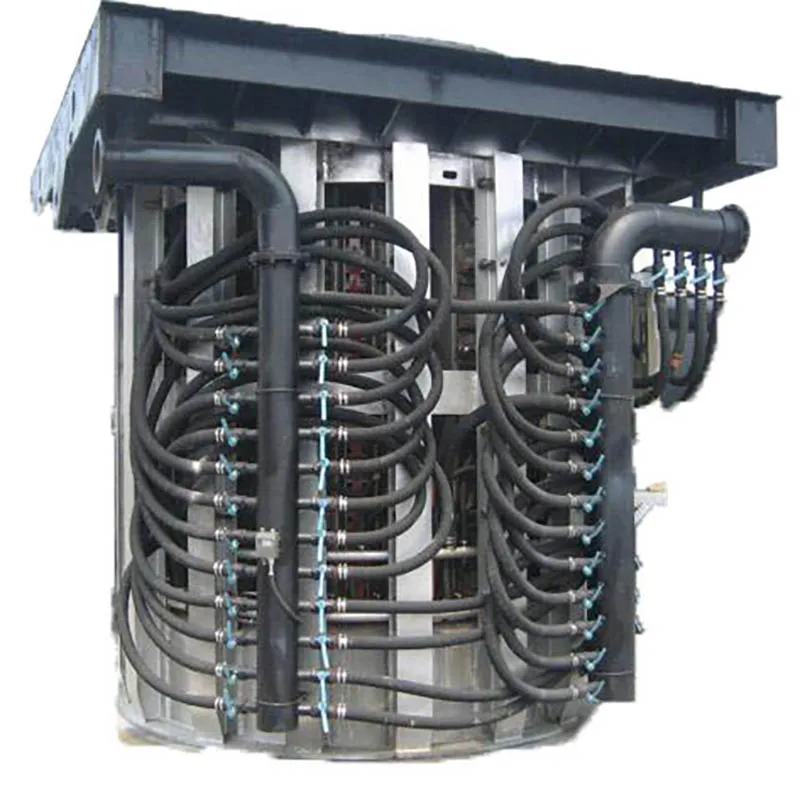

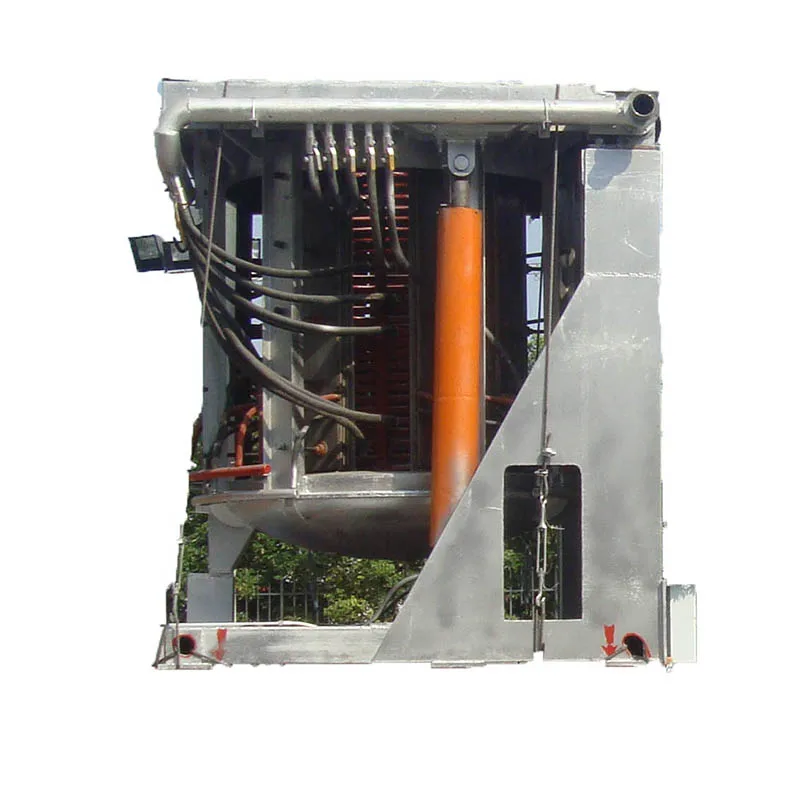

Medium frequency induction furnace heating power supply, worktable, induction coil, feeding mechanism, infrared thermometer, etc.

1.electric type melting furnace

2.can melt steel scrap,copper,aluminum,lead,etc

3.melting speed fast

4.easy opearation and maintance

5.auto tilting type

Product Name | 20ton rotary induction smelting furnace 1400c scrap iron steel melting furnace |

Material | Aluminum Shell/Steel Shell/Copper |

Major Equipment | Electric furnace body 2 sets, hydraulic or mechanical tilting furnace 2 sets, control table 1 set, intermediate frequency control cabinet (6 pulse 1, 12 pulse 2, 24 pulse 4), low voltage control cabinet (6 pulse 1, 12 pulse 2, 24 pulse 4), capacitor cabinet 1 set, water-cooled cable 4 or 8; (5 tons or more with) water temperature alarm 1, leakage alarm 1; crucible mold 1, hydraulic steel pipe 1 batch, copper Row 1, water tank 3. Transformer, cooling tower, furnace builder, lining ejector, furnace cover. |

Product Features | KGPS, IGBT, single power supply or dual power supply technology. It can realize PLC (SIEMENS) whole process monitoring. |

Product Application | Induction furnace is used for smelting or insulating ferrous metals, non-ferrous metals, sponge iron, such as scrap iron, scrap steel, copper, aluminum and so on. Complete working equipment such as continuous casting machine, rolling mill, mainly used for the production of billet, steel bar, angle steel, H-beam, I-beam, etc. Using KGPS, IGBT, single or double power supply technology, PLC (Siemens) can be realized throughout the monitoring. |

Practical use | 1. heat treatment: partial or whole hardening, annealing, tempering and diathermy of all kinds of metals. 2. hot forming: whole forging, partial forging, hot upsetting and hot rolling. 3. Welding: brazing of various metal products, welding of saw blades and blades, welding of steel pipes and copper pipes, welding of dissimilar metals. 4. metal smelting: (vacuum, smelting, casting and evaporating coating) of gold, silver, copper, iron and aluminum. 5. Other applications of high-frequency heater: semiconductor single crystal growth, thermal coordination, bottle mouth heat seal, toothpaste skin heat seal, powder coating, metal implanted plastics, etc. |

Induction Furnace Type | Induction furnace can be divided into high frequency furnace, medium frequency furnace and power frequency furnace according to the frequency of power supply; melting furnace, heating furnace, heat treatment equipment and welding equipment according to the purpose of technology; and can also be classified according to its structure and transmission mode. Commonly used induction furnace is usually summed up as a central induction furnace, coreless induction furnace, vacuum induction furnace, induction quenching equipment and induction head heating equipment. |

Forging Furnace Specification and Heating Capacity | ||||

Specification | Max output power | Heating capability for common materials | ||

LHF-25KW | 25KW | Recommending for φ15-30mm steel bar heating | ||

LHF-45KW | 45KW | Recommending for φ15-30mm steel bar heating | ||

LHF-70KW | 70KW | Recommending for φ15-30mm steel bar heating | ||

LHF-110KW | 110KW | |||

LHF-160KW | 160KW | ecommending for φ15-30mm steel bar heating | ||

Induction furnace is used for heating copper bar, iron bar and aluminium bar.

Ultra-small size, mobile, covers only 0.6 square meters, easy to use with any equipment.

Installation, debugging and operation are very convenient, you can learn it immediately.

Induction heating makes the bar heated to the required temperature in a very short time, greatly reduces metal oxidation, saves material and improves forging quality.

Medium-frequency heating of rods above_15 is more heat-permeable, more uniform and faster.

Work 24 hours without interruption.

Automatic feeding.

Power saving, environmental protection, cost reduction and human resources expenditure.

Convenient replacement of the furnace body to meet the different requirements of overall heating or end heating of bars.