Экспорт из Бангладеш джутовые палочки машина для производства древесного

- Категория: Carbonization Stove >>>

- Поставщик: Zhengzhou,Dingli,New,Energy,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.22 $* | 0.46 $* |

| Aug-18-2025 | 0.5 $* | 0.84 $* |

| Jul-18-2025 | 0.80 $* | 0.37 $* |

| Jun-18-2025 | 0.81 $* | 0.7 $* |

| May-18-2025 | 0.1 $* | 0.27 $* |

| Apr-18-2025 | 0.74 $* | 0.13 $* |

| Mar-18-2025 | 0.81 $* | 0.91 $* |

| Feb-18-2025 | 0.67 $* | 0.0 $* |

| Jan-18-2025 | 0.45 $* | 0.20 $* |

Характеристики

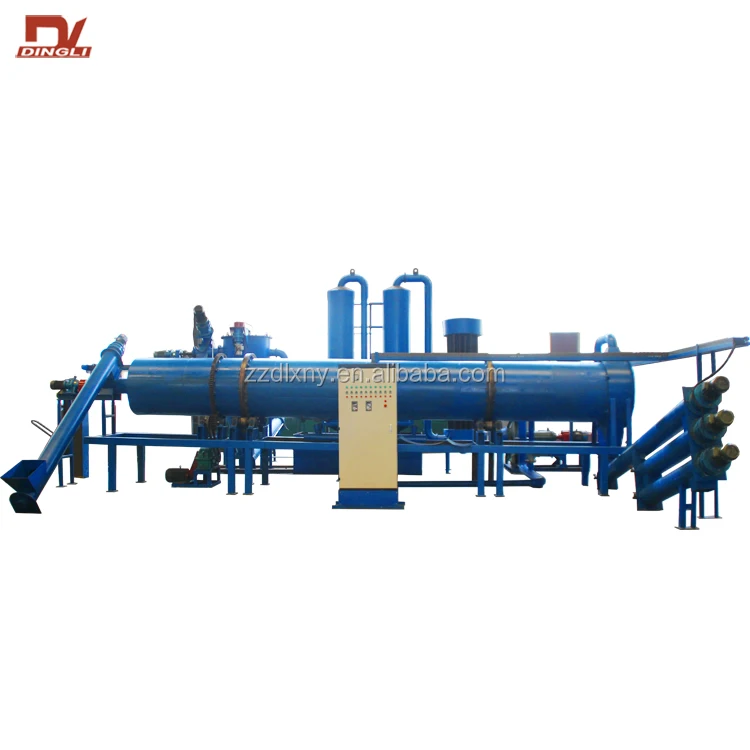

Product Introduction

Main Features

1) Gas preparation through the early stage of the new type of gasifier.

2) Matching a flue gas purification, heat exchange system, and cooling system. Making the heat steam into water. Flue gas can be converted combustible gas to combustion cycle.

3) Configuration a frequency conversion feeding machine, which is automatic feeding. The speed of feeding can be adjustable.

4) Matching a rotary drum carbonization host,in order to satisfy the production requirements.

5) Configuration a cooling discharging machine to cooling the final products and export final product.

6) Configuration a control cabinet.The temperature and speed can be easy to control. The continuous rotary drum carbonization equipment uses a PLC automatic control cabinet.

7) The equipment have a carbonized color display. The production status should be showing clear.

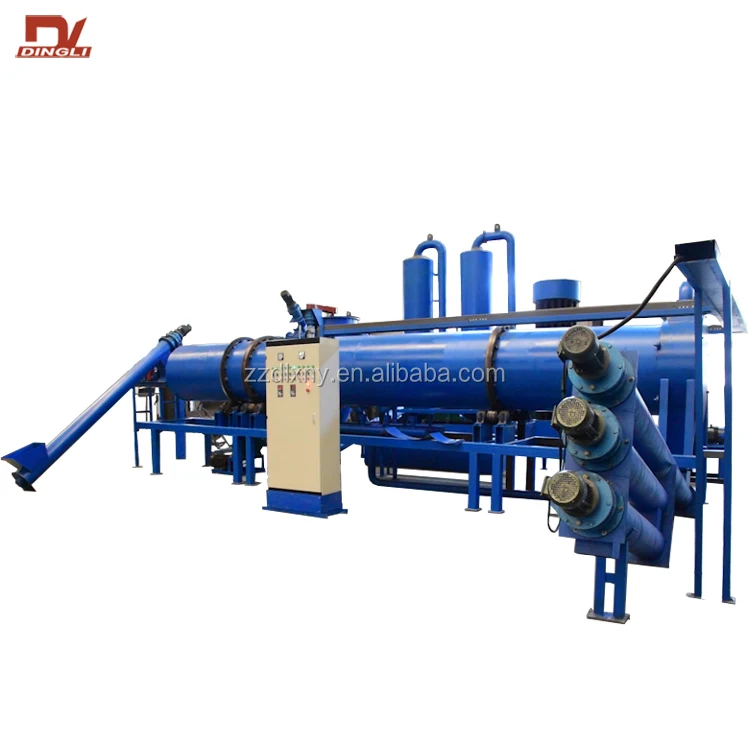

Below is Carbonizing Process

First the biomass material is ignited in the gasifier.

The flue gas produced by burning after spraying, cooling, purification process, it produces the pure combustible gas (carbon monoxide, methane, ethane, etc.).

As the early stage of the carbonization of heat source, through early warming of the carbonizer, to feed the material when the heat reaches the special temperature.

The combustible gas that carbonation process of flue gas by spraying, cooling, purification process into burned secondary. According to this methods of circulation, sufficient to achieve a self-sufficient, then achieve the effect of energy saving.

The flue gas through purification, to reach the environment production and flue gas emissions free. Which is reached to the standards of waste gas emptying.

The temperature of carbonization reach a 600 ℃ to 900 ℃ in the process. According to the characteristics of material, the temperature can be adjusted according to the requirements.

Below is Working Principle

Other Related Technical Parameters

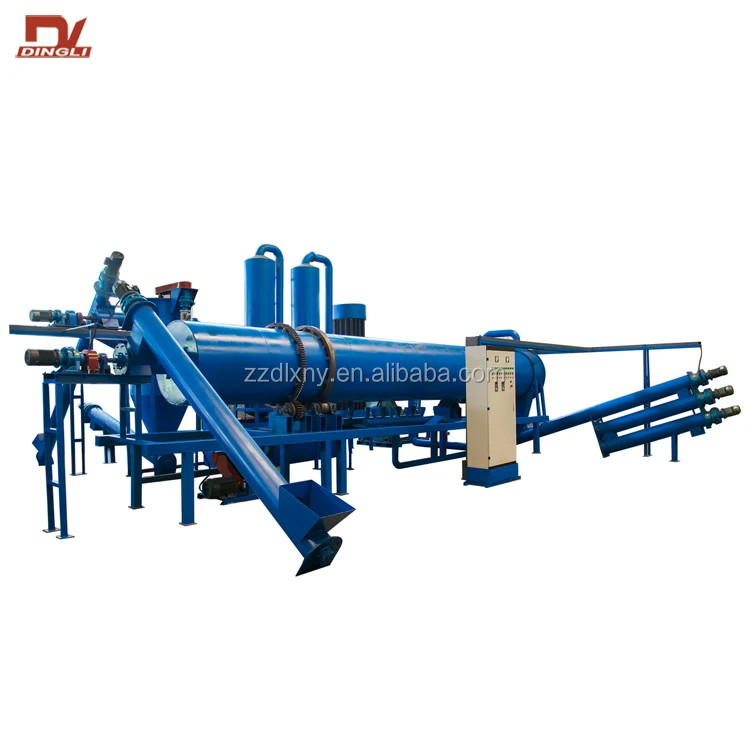

We can help optimize the drying process according to the property of different materials, production scale, application requirements, cost control, automation level and site condition.

Model | Output Capacity (kg/h) | Power (KW) | Dimension (M) | Host RPM (revolutions per minute) | ||||

THJ1000 | 400-600 | 25 | 9*1.5*2.7 | 3-5 | ||||

THJ1200 | 800-1200 | 27 | 12*1.7*2.9 | 3-5 | ||||

THJ1500 | 1500-2000 | 32 | 12*2.0*3.2 | 3-5 | ||||

THJ1800 | 2500-3000 | 39 | 12*2.3*3.3 | 3-5 | ||||

Except above models, we also can supply special model according to your requirements. | ||||||||

Below is Dingli Group Packaging & Shipping:

Your device will be packed well in container and suit for long ocean shipping.

Below is Dingli Group Service Items:

Pre-sale

1. According to your needs, select right model for you.

2. According to your special requirements, design customized solution and manufacture customized products for you.

3. Welcome your visit.

Sale

1. Sign contract, pay deposit, we arrange production.

2. Product acceptance.

3. Help you formulate construction scheme.

After-sale

1. Assign engineer service for you on-site freely.

2. Install and adjust device, train how to operate.

3. After installation, leaving 1-2 technical staff to help you on-site production, until achieve customer satisfaction.

Biomass Rotary Dryer

Sawdust Dryer

Chicken Manure Dryer

Beer Yeast Drum Dryer

Brewer Spent Grain Dryer

Biomass Wood Pellet Production Line

Coconut Fiber Dryer

Coal Slime Dryer

Belt Dewatering Machine

Dingli Group Advantage:

1. Over 200 employees, 98% professional technical personnel;

2. Factory size over 15,000 square meters;

3. 480 Inventions & Patents

4. Exported over 80 countries,300 global partners;

5. Rank 3rd in China Drying Industry;

6. Customize Drying Production Line.

Below are Dingli Dryer Factory & Sales Team & Production Workshop Pictures:

Below are Dingli Group Honors & Certificates & Patents:

Below are Dingli Customers Visiting:

Dingli Dryer Production Line has exported to over 80 countries with 300 foreign partners, such as Germany, Britain, United States, Italy, Israel, Chile, Thailand, Russia, Vietnam, India, Cambodia, Indonesia, Malaysia, Thailand etc.

Below are Installation Sites of Our Customers:

After reach deals, Dingli Engineer will fly to your address, install and adjust machine for you freely.

Also train you operation skills, until you are satisfied.

Q: What is your Business Model? Trading company or factory?

A:We are a 15 years factory, all our machinery are manufactured by ourselves, factory direct sales, product quality and after-sales service can be guarantee.

Q: Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year. Our company is located in Zhengzhou Henan province, China, you can come here by air or train.

The nearest airport is Zhengzhou Xinzheng International Airport, and the Airport Code is CGO.

We will pick you up at airport. Welcome to visit our factory.

Q: What is the Quality of your products?

A: Dingli Group products come with best quality, and our products passed CE certification, exported to lots countries around the word, such as Australia, Malaysia, India, Italy ,Indonesia, Vietnam, Philippines, Korea, Brazil, Argentina, Russia, South Africa, etc. You can rest assured with the quality absolutely.

Q: What is the Installation of your products?

A: Dingli Group has several experienced technicians with passports ready to go for installation, when installation service is needed, the client should pay for technicians' round way air tickets, food and lodging, most importantly to guarantee the technician's safety.

Q: What should I provide to get the suitable quotation?

A: 1.What is the raw material for the production line?

2. What is the capacity per hour you required?

3. What is the maximum input size of the raw material?

4. What is the output size and application for the final product?

You can send inquiries from this page.Once we get your answers,we can provide you the best quotation immediately.

Remarks: The price will depend on different models.