Промышленный высокочастотный индукционный нагревательный генератор для нагревательного металлического стержневого

- Категория: Industrial Furnace >>>

- Поставщик: Luo,Yang,Hongteng,Electrical,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.23 $* | 0.66 $* |

| Aug-17-2025 | 0.91 $* | 0.65 $* |

| Jul-17-2025 | 0.21 $* | 0.4 $* |

| Jun-17-2025 | 0.94 $* | 0.64 $* |

| May-17-2025 | 0.33 $* | 0.43 $* |

| Apr-17-2025 | 0.16 $* | 0.34 $* |

| Mar-17-2025 | 0.25 $* | 0.41 $* |

| Feb-17-2025 | 0.54 $* | 0.99 $* |

| Jan-17-2025 | 0.76 $* | 0.52 $* |

Характеристики

Furnace body Part :

1. Furnace body frame use national standard aluminum, nice appearance looking ,not give hot.

2. The induction coil inside the furnace body is insulated by two insulation treatment. First spray high temperature insulating paint. The second is wrapped around the fiberglass ribbon. The service lifetime of the treated furnace lining and induction coil will be more than doubled.

3. The water inlet and outlet of furnace body adopt water-cooled copper plate to improve the service life of furnace lining.

4. The top of furnace body is designed with sliding cover design, which makes it more convenient for maintenance personnel to maintain the furnace body.

5. The cooling water pipe of the furnace body adopts high temperature carbon-free hose, and the water hose can work for a long time under the ambient temperature of -18c --120C. The service lifetime is more than three years.

Feeding System Part :

1. The feeding system adopts pinch roll feeding, which is suitable for bar diameter range of 40-120mm.

2. The feeding speed is controlled by variable frequency motor and the feeding speed is adjustable.

3. The pitch roller feeding motor and the reducer all adopt aluminum shell, which can effectively prevent the hot around the coil.

WE HAVE RICH EXPERIENCE IN PRODUCING HIGH FREQUENCY INDUCTION HEATING GENERATOR MOST USED IN FOLLOWING APPLICATIONS:

1.High frequency induction heating generator used in forging factory.The furnace are electric type,most used for preheat material before forge.Normally heating temperature requirement 1200C before forge to press any shapes.Induction heating forging furnace will have multi protection,automatic conveyor,self warning ,temperature controller.can heat preheat all kinds of parts.

2.Used in 3PE anticorrosion production line.induction heating forging furnace used for heating pipe before coating.most use for heat water oil gas pipe to 200-500C,then can coating anti corruption painting.we have lots of similiar projects in china mainland.

3.Used in Rebar production line.induction heating forging furnace most used for reheat the billets to 1200C,or heat cold billets from casting machine to 1200C,before goes into rolling mill.Can heat all kinds of square billets such as 90*90mm,100*100mm,120*120mm 6m long bars.

4.we also have melting furnace can used in any other kinds of foundry factory.furnace to melt scraps metal to recycling.

Automatic tilting melting furnace

Luoyang Hongteng Electric Equipment Co.,ltd are expert of induction furnace, over 15 years prouction expericence. Professional technical team and service team. Sincerely looking forward to your visit our factory .

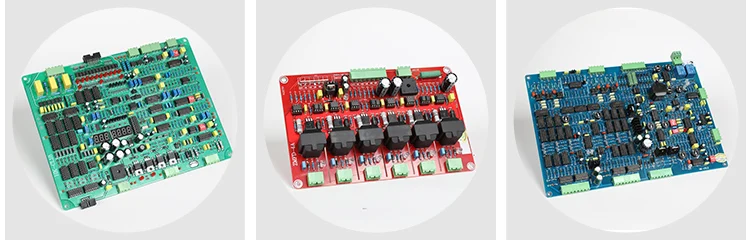

Electric board

Main control board is our company self-made, according to advanced technology. high quality. We have many stocks.

Main control circuit board as the main part of the machine, we made in their research and development, and adopted by the company and built since the automatic welding and testing equipment to ensure that each set of machine can achieve the best effect, and we have main control board in stock lone time, can satisfy the parts supply problems.

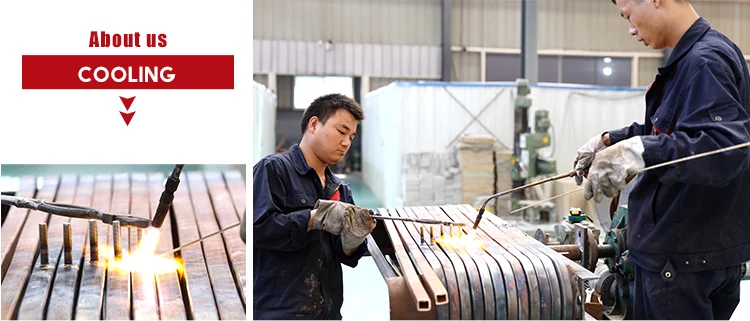

Induction coils

copper tube

Drawings

technical drawings of automaic tilting induction melting furnace .

meeting

learning traing product knowledge

test maching runing

our technical staff are test machine running

1: Are you the Manufacturer or a trading company?

We are direct manufacturer specialized in produce in machinery for 15 years.Our factory located in high industry zone,Luoyang city,henan province,where is the biggest industry machinery manufacturing base in china.

2: Why should we choose Hongteng?How do you ensure the quality?

We have professional research staff and strict in Production,inspection and debugging and package process.We always insist on supply good pre-sales,order following,after sell service for our customers.

We have professional QC person inspect machinery production.After production finished,all machines will be testing & debugging carefully before shipment.

3: Which kind of power supply do you supply? Electricity or gas?

Electricity.

Welcome to visit us,and have a face to face negotiation.

5: How do you control the quality?

We have QC team comply with TQM to ensure the quality. Each step is in compliance to the standards. At the same time, we will take photos and shoot video for you if you need.

6: Which county do you exported to ?

We have already exported our machines to many famous company in many countries, such as Vietnam,Indonesia,Myanmar,Qatar,Iran,Ukraine etc . Welcome customers to visit our factory.

7: How about your after sales service?

After customers get machines,We will send our engineers to customer's workshop.We will supply installation & debugging & training service for customers till machine normal production.