Печь для переработки ковша VD/VOD 50 тонн 100 150

- Категория: Industrial Furnace >>>

- Поставщик: Shanghai,Electric,Heavy,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 13090.66 $* | 13745.52 $* |

| Aug-20-2025 | 12980.89 $* | 13629.4 $* |

| Jul-20-2025 | 10890.73 $* | 11435.24 $* |

| Jun-20-2025 | 12760.30 $* | 13398.18 $* |

| May-20-2025 | 11110.81 $* | 11666.3 $* |

| Apr-20-2025 | 12540.26 $* | 13167.35 $* |

| Mar-20-2025 | 12430.23 $* | 13052.2 $* |

| Feb-20-2025 | 12320.48 $* | 12936.93 $* |

| Jan-20-2025 | 12210.98 $* | 12821.19 $* |

Характеристики

Product Description

Ladle refining furnace is used for molten steel refining. The structure type is divided into heating bridge, fourth column, transverse arm rotation and large package rotary table for users to choose.

The equipment of ladle refining furnace is composed of ladle, ladle truck and towing cable, furnace cover, electrode lifting mechanism, short net, water cooling system, hydraulic system, argon system, furnace transformer, high voltage cabinet, low voltage electric and automatic control system, etc. The tonnage of furnace is from 10 tons to 300 tons.

Product Name | VD/VOD ladle refining furnace 50 Ton 100 Ton 150 Ton Ladle Refining Furnace |

Material | Aluminum Shell/Steel Shell/Copper |

Function | 1. Arc heating at normal pressure, temperature measurement and sampling, and final temperature precise control can optimize the pouring temperature; 2. Refining, desulfurization, deoxidation, degassing and inclusion removal of synthetic slag; 3. Bottom blowing argon stirring makes the temperature of molten steel uniform, the composition uniform and pure; 4. Alloy fine-tuning makes the composition control accurate, and the final required chemical composition can be efficiently achieved by ferroalloy elements or aluminum or wire feeding. 5. With wire feeding machine, desulfurization and deoxidation of molten steel can be achieved, morphological distribution of inclusions can be changed, and alloy elements can be accurately controlled. At the same time, the alloy yield is high, the temperature of molten steel is low, and the environmental pollution is small. 6. As the buffer equipment between primary smelting furnace and continuous casting machine, it ensures the matching production of primary smelting furnace and continuous casting, and realizes multi-furnace continuous casting. |

Characteristic | 1. The water-cooled furnace cover is equipped with a dust removal interface which can adjust the size of the delayed outlet, so that the furnace can always operate in a micro-positive pressure reducing atmosphere; 2. The copper-steel composite conductive cross arm is used to reduce the diameter of the electrode distribution circle and improve the service life of the furnace lining. 3. It is equipped with automatic or manual temperature measuring and sampling device to accurately measure molten steel temperature. 4. Large cross-section water-cooled cable, compensator and copper-steel composite conductive cross-arm are used in large current system to reduce the main circuit impedance. 5. The automatic feeding device of alloy and slag is used to accurately measure the alloy and slag added into the package. 6. It is equipped with PLC control system and smelting model. |

Parameter

No. | Product Name | Unit | Data | Remarks |

1 | Block of LF furnace | Seat | 1 | |

2 | To deal with every steel water | t | 60 | 70 max |

3 | LF furnace transformer rated capacity | MVA | 1.2 | 20% overload |

4 | Primary Voltage | KV | 35 | |

5 | Secondary Voltage | V | 270-250-170 | No-loading adjust voltage 6 grade |

6 | Secondary Current | A | 27700 | |

7 | Heating rate | ℃/min | 4.0 | Max:6.0 |

8 | Electrode diameter | mm | 400 | UHP |

9 | Average refining cycle | min | 35 | |

10 | Electrode moving distance | mm | 2500 | |

11 | Electrode moving speed | M/min | 3--4 | |

12 | Refining ladle car load | T | 150 | |

13 | Refining ladle car speed | M/min | 12 | |

14 | Furnace hearth diameter | mm | Ф2500 | 60ton molten steel surface |

15 | Ladle upper diameter | mm | Ф3000 | |

16 | Ladle height | mm | 3700 | |

17 | Free space height | mm | 450 | 60ton molten steel surface |

18 | Cooling water inlet | ℃ | ≤34 | |

19 | Temperature Rise | ℃ | ≤15 | |

20 | Cooling water flow | M3/h | 200 | |

21 | Water pressure | MPa | ≥0.35 | |

22 | Power Supply | V | 35000(380-220) | High voltage(lOW) |

23 | Frequency | Hz | 50 | |

24 | Compressed air | Mpa | ≥0.4 | No water no oil |

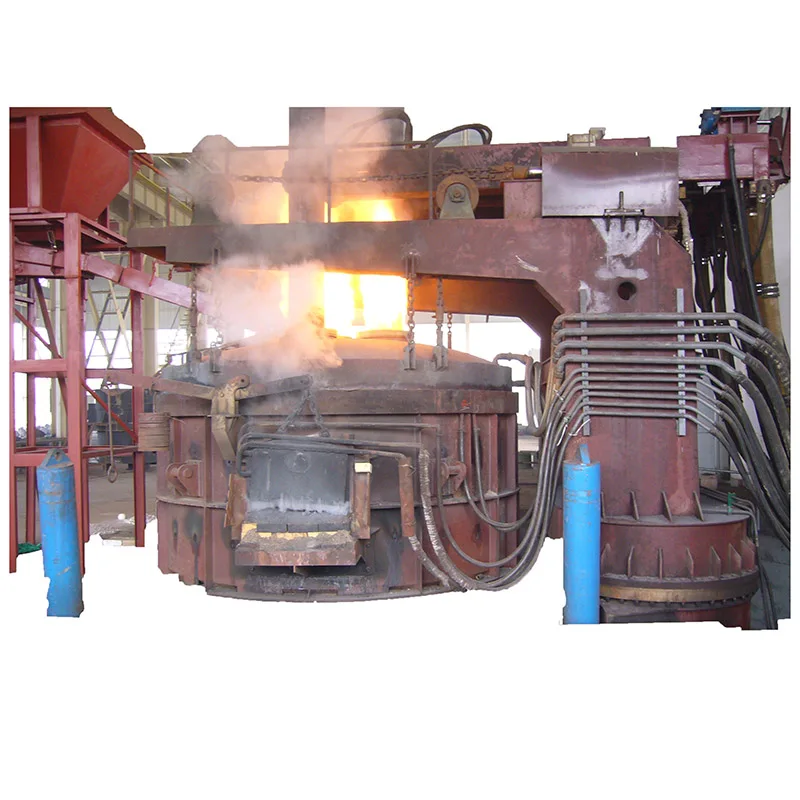

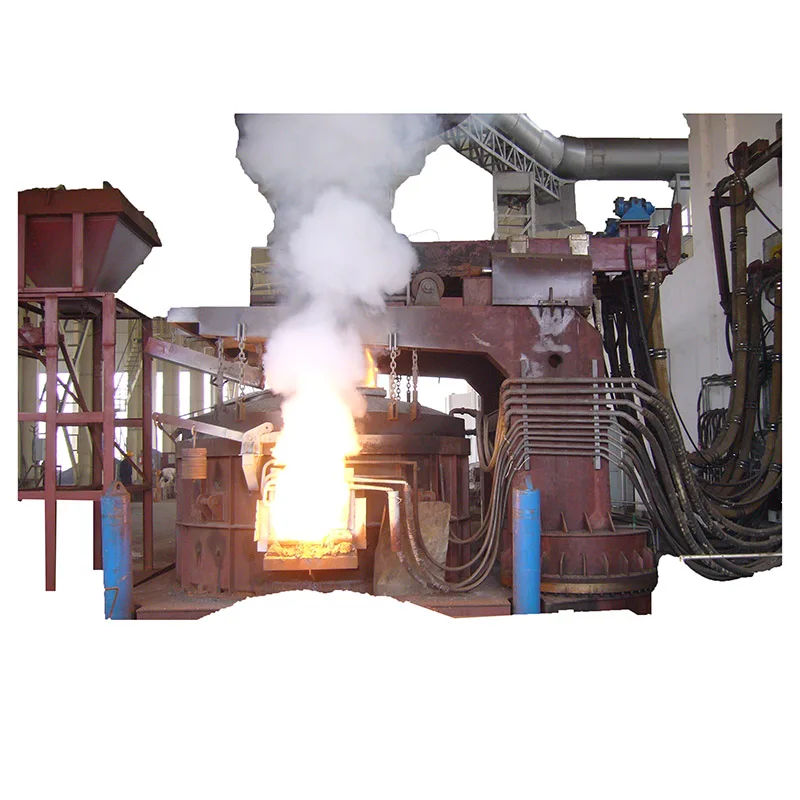

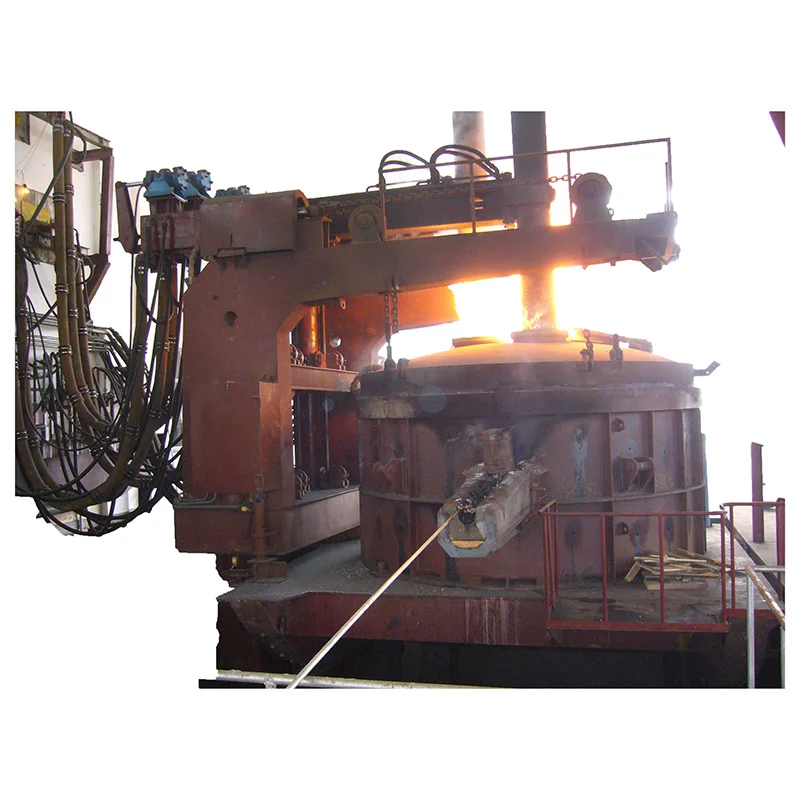

Products Show

Packing & Delivery

Похожие товары

ATPARTS u тип mosi2 нагревательный элемент для печи

US $40.00-$50.00

Печь для отжига колокольчикового типа

US $11900-$12000