Алюминиевая печь для пайки радиатора с непрерывным

- Категория: Industrial Furnace >>>

- Поставщик: Wuxi,Wondery,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.84 $* | 0.16 $* |

| Aug-20-2025 | 0.40 $* | 0.60 $* |

| Jul-20-2025 | 0.9 $* | 0.89 $* |

| Jun-20-2025 | 0.46 $* | 0.40 $* |

| May-20-2025 | 0.56 $* | 0.91 $* |

| Apr-20-2025 | 0.92 $* | 0.59 $* |

| Mar-20-2025 | 0.28 $* | 0.20 $* |

| Feb-20-2025 | 0.88 $* | 0.44 $* |

| Jan-20-2025 | 0.10 $* | 0.80 $* |

Характеристики

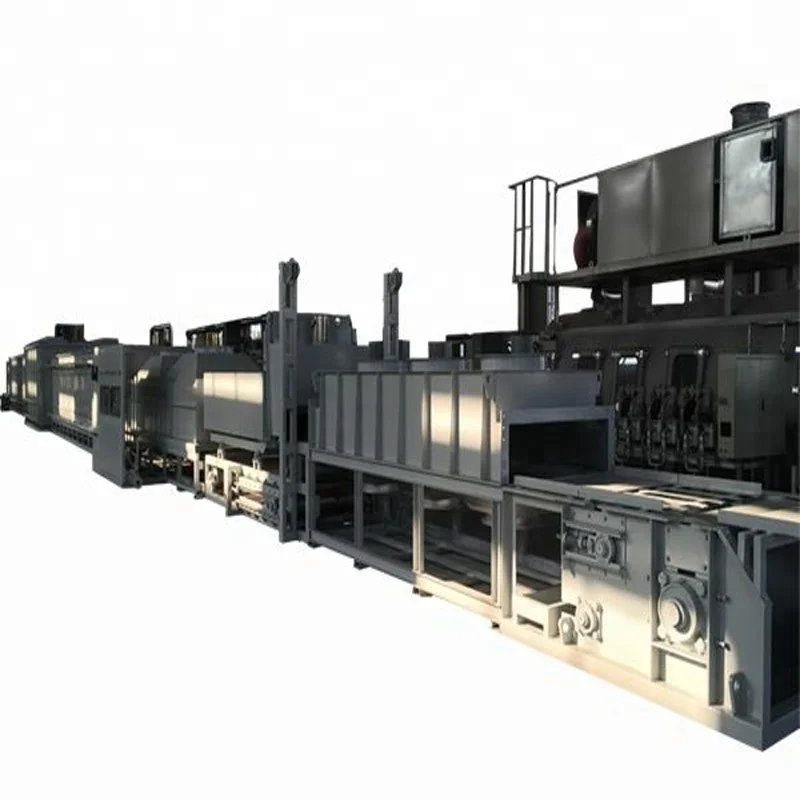

Product Application

The aluminum radiator brazing furnace is used to braze aluminum heat exchangers such as radiators, intercoolers, evaporators, and heater radiator under protective nitrogen atmosphere. The flux used is NOCOLOK flux. The aluminum radiator brazing furnace is also called as radiator brazing furnace, brazing furnace, aluminum brazing furnace, continuous brazing furnace, atmosphere brazing furnace, etc.

Parameters of Aluminum Radiator Brazing Furnace Line |

Mesh belt operation surface height (to the ground): 900mm; Mesh belt speed: 300~1200mm/min (inverter control) Effective working size: 1200mm(width)×220mm (height) |

Supply Scope of Aluminum Radiator Brazing Furnace |

1) Fluxing system..................................................................1 set 2) flux mixing and supply device...................................................1 set 3) drying oven........................................................................1 set 4) front curtain chamber............................................................1 set 5) brazing oven........................................................................1 set 6) water cooling chamber............................................................1 set 7) rear curtain chamber...............................................................1 set 8) air cooling chamber..................................................................1 set 9)Driving device........................................................................3 sets 10) electrical control system .........................................................1 set 11) water and nitrogen piping system................................................1 set |

Main Features

1) The whole aluminum radiator brazing furnace adopts high performance porcelain fiber cotton material for heat preservation purpose. The aluminum radiator brazing furnace is able to rise to 630℃ from the ambient temperature in around 2 hours.

2) The muffle of the brazing oven is once-formed by the large size bending machine, and is made from Sweden 316L steel plate and 304 steel plate. 10M muffle is formed by one-time bending, and only there is one v-slot at the bottom of the muffle. The one-time forming muffle could reduce the misshapening effect at welding and also deformation at the heating process.

3) The zones of the aluminum radiator brazing furnace are divided based on upper, lower, rear and back area. The heating power is adjusted through PID regulator so that the furnace could achieve an ideal temperature uniformity of ±1℃. The brazing area could achieve a temperature uniformity of ±2℃ so that it could meet the brazing requirements.

4) The temperature controller has the PID regulation function to achieve a smooth temperature rise. Also the temperature controller has the over-temperature alarm. The mesh belt of the aluminum radiator brazing furnace is steplessly regulated through the inverter. The driving mechanism is started up in the acceleration manner, and stopped in the deceleration manner to reduce the tension of the mesh belt.

5) the aluminum radiator brazing furnace has a complete control system integrating intelligent control, alarm and protection system. The real-time temperature recording function provide the process data of different products.

6) The area of the fluxing chamber which contacts the flux is made of stainless steel material. The two side walls of the fluxing chamber are both set with an observation window to observe the fluxing performance. The fluxing nozzles have a 90º fan-shape spraying to prevent nozzle blockage. There is a filtering net for recycling the flux to prevent damage to the fluxing pump.

7) The dry air cooling room is set with a slag cleaning chamber. There is a side door of the slag cleaning chamber for allowing the worker to clean the flux slags. In comparison to the traditional water cooling chamber, the dry cooling room don't have the risk of corrosion because of water and deformation of the chamber because of cold and heat. There is no need for cooling water.

8) power at temperature rising stage: 100%; power at the brazing stage: ≤60%