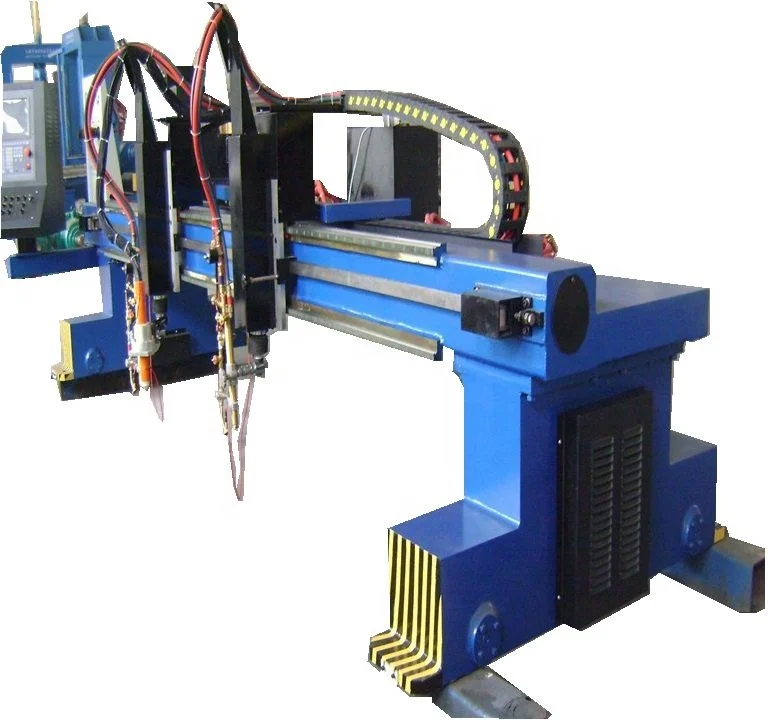

Многоголовочный станок для резки стальных полос станка плазменной и пламенной конструкций

- Категория: Газорезательная машина >>>

- Поставщик: Wincoo,Engineering,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 28322.74 $* | 29738.7 $* |

| Aug-19-2025 | 28084.98 $* | 29488.34 $* |

| Jul-19-2025 | 23562.30 $* | 24740.63 $* |

| Jun-19-2025 | 27608.94 $* | 28988.3 $* |

| May-19-2025 | 24038.92 $* | 25240.5 $* |

| Apr-19-2025 | 27132.27 $* | 28489.33 $* |

| Mar-19-2025 | 26894.64 $* | 28239.37 $* |

| Feb-19-2025 | 26656.79 $* | 27989.73 $* |

| Jan-19-2025 | 26418.17 $* | 27739.11 $* |

Характеристики

Product Description

Developed and designed in-house and tested in practice, we have produced a series of cutting machines and cutting lines that will be regarded as industry leading since 2003. All of our CNC cutting machines can be equipped with oxy-fuel and/or plasma cutting equipment.

CNC-CG series is our standard cutting machine which not only can cut different profiles/shapes but also can cut strip/straight plate.

Guoheng earned its global market position by offering extremely innovative cutting solutions for customers in steel construction,offshore, shipbuilding, process and crane building industry.

We also provide user-friendly broad choices and options that allow you to configure your CNC cutting system with the capacities,speed and accuracy of your needs.

CNC-CG series is our standard cutting machine which not only can cut different profiles/shapes but also can cut strip/straight plate.

Guoheng earned its global market position by offering extremely innovative cutting solutions for customers in steel construction,offshore, shipbuilding, process and crane building industry.

We also provide user-friendly broad choices and options that allow you to configure your CNC cutting system with the capacities,speed and accuracy of your needs.

Model | CNC-CG3000 |

CNC-CG4000 | |

CNC-CG5000 | |

CNC-CG6000 | |

CNC-CG7000 | |

CNC-CG8000 |

Direction for main feature

1.Robust all steel fabrication with stable structure and good rigidity, and no deformation after long time using;

2.Micro-step SH-2200AH CNC system;

3.Single side gear and rack driving;

4.Capacitive height controller and auto-igniter;

5.Australia FASTCAM auto programming and nesting software;

6.Both longitudinal and transverse drives adopt Japan Panasonic high precision A.C. servo motor, Germany NEGUART high precision gear reducer and high precision gear and rack.

7.The brushless AC servo motor has high torque, high resolution and high inertia.

Longitudinal rail is fine machining rail. Rack material is 45# steel, fixed in rail by bolt in sections.

8.Advanced PC-Based CNC controller with faster processing speed & greater accuracy improves productivity. This CNC controller features a Windows operating system and colored LCD screen.

2.Micro-step SH-2200AH CNC system;

3.Single side gear and rack driving;

4.Capacitive height controller and auto-igniter;

5.Australia FASTCAM auto programming and nesting software;

6.Both longitudinal and transverse drives adopt Japan Panasonic high precision A.C. servo motor, Germany NEGUART high precision gear reducer and high precision gear and rack.

7.The brushless AC servo motor has high torque, high resolution and high inertia.

Longitudinal rail is fine machining rail. Rack material is 45# steel, fixed in rail by bolt in sections.

8.Advanced PC-Based CNC controller with faster processing speed & greater accuracy improves productivity. This CNC controller features a Windows operating system and colored LCD screen.

Description of main feature

9.Germany IGUS transverse drag chain;

10.Limit switch for gantry travel;

11.Heat treatment to main welding parts after welding; sand blasting treatment to main welding parts before painting;

12.High intensive heat-resisting gas supply pipe;

13.Backfire arrester and solenoid for cutting oxygen for torch;

14.All motion parts have lubrication system;

15.Main electric elements are ABB/Siemens brands;

10.Limit switch for gantry travel;

11.Heat treatment to main welding parts after welding; sand blasting treatment to main welding parts before painting;

12.High intensive heat-resisting gas supply pipe;

13.Backfire arrester and solenoid for cutting oxygen for torch;

14.All motion parts have lubrication system;

15.Main electric elements are ABB/Siemens brands;

Detailed Images

CNC-CG series is our standard cutting machine which not only can cut different profiles/shapes but also can cut strip/straight plate.

Size Information

Parameter for machine

Model | CNC-CG3000 | CNC-CG4000 | CNC-CG5000 | CNC-CG6000 | CNC-CG7000 | CNC-CG8000 | ||||||

Drive system | Single side gear and rack driving | Double sides gear and rack driving | ||||||||||

Rail span mm | 3,000 | 4,000 | 5000 | 6000 | 7000 | 8000 | ||||||

Valid working width mm | 2,200 | 3,200 | 4200 | 5200 | 6200 | 7200 | ||||||

Strip/straight cutting width mm | 80-2,200 | 80-3200 | 80-4200 | 80-5200 | 80-6200 | 80-7200 | ||||||

CNC flame torch | 2groups | |||||||||||

Strip/straight cutting torch | 9groups | |||||||||||

Rail length mm | 15,000 (valid cutting length 12,5000), fine machining I-rail | |||||||||||

Torch lift stroke mm | 150 | |||||||||||

Flame cutting speed mm/min | 50-1,000 (setting as per cutting technology) | |||||||||||

Fast return speed mm/min | 4,000 | |||||||||||

Flame cutting material | MS | |||||||||||

Flame cutting thickness mm | 6-150 (single torch), piercing thickness≤100 | |||||||||||

Cutting surface roughness | Ra12.5-25 | |||||||||||

Positioning accuracy mm/m | ±0.5 | |||||||||||

Intersection point deviation mm | ≤0.5 (800*800 industry standard prescribed figure lineation) | |||||||||||

Diagonal error mm | ≤0.5 (square lineation) | |||||||||||

Power supply | AC220V 50HZ single phase | |||||||||||

Above are our standard models and parameters, and it can be designed and manufactured on request. | ||||||||||||

Packing&Shipping

Export packing and sea transportation, or other means of transportation.

After Sales Service

Quality assurance date

We will provide one-year warranty and support online and offline technical support.If you need, we will send engineers to help

you.

you.

Company Introduction

Wincoo Engineering Co., Ltd (WINCOO) is engaged in bringing the most suitable solutions/equipments for client, fabricators, EPC/C companies on pipe fabrication, tank construction, pipeline construction,industrial production lines, clean energy project and other industrial field.

Our Services & Strength

We have ability of providing workable solutions to support clients to be awarded with shorter project execution time, fewer

man-hour cost and higher efficiency construction/fabrication method and better quality during phase of project bidding.

Based client’s facility/site space availability, we are able to study/design and present matched configurations on project

schedule, quality, cost and productivity to guarantee production pace is accordance with project requirement.

To support project execution, we are always ready to work as fireman to give prompt supply on project materials from different consumables, tools, equipments/machines to special merchandise. With flexibility, we are also glad to perform as procurement agent in China to seek required supply resources.

man-hour cost and higher efficiency construction/fabrication method and better quality during phase of project bidding.

Based client’s facility/site space availability, we are able to study/design and present matched configurations on project

schedule, quality, cost and productivity to guarantee production pace is accordance with project requirement.

To support project execution, we are always ready to work as fireman to give prompt supply on project materials from different consumables, tools, equipments/machines to special merchandise. With flexibility, we are also glad to perform as procurement agent in China to seek required supply resources.