1000 кВт электрическая индукционная печь для

- Категория: Industrial Furnace >>>

- Поставщик: Luo,Yang,Hongteng,Electrical,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 10710.9 $* | 11246.4 $* |

| Aug-19-2025 | 10620.32 $* | 11151.51 $* |

| Jul-19-2025 | 8910.27 $* | 9356.97 $* |

| Jun-19-2025 | 10440.87 $* | 10962.96 $* |

| May-19-2025 | 9090.71 $* | 9545.19 $* |

| Apr-19-2025 | 10260.57 $* | 10773.19 $* |

| Mar-19-2025 | 10170.44 $* | 10679.1 $* |

| Feb-19-2025 | 10080.34 $* | 10584.67 $* |

| Jan-19-2025 | 9990.72 $* | 10490.91 $* |

Характеристики

1000kw electric induction heating forge furnace for forging

Features of steel bar electric induction heating forge furnace

1) turn on and turn off easily,and power faihure.

2)Adopt constant power to control the circuit, maintain constant power while malting, and keep faster melting rate.

3)Set up over voltage, over current and water deficient protector, and run safely.

4)The motherboard adopts CAD technology, integrated circuit board, low-fault-rate, easy-manipulating,effortless maintenance.

5)Zero voltage starts up softly, high initial ower, no impact for the electric network.

6)Apply to melting ferrous metal and non-ferrous metal like copper, aluminum, brass, steel,iron,stainles steel etc...

Medium frequency electric heating forge furnace - power supply

Main technical parameters

| Specifications of steel bar induction heating forge furnace | |||

| Model | KGPS-1000KW | Input voltage | 380V |

| Input current | 1600A | DC current | 3000A |

| DC Voltage | 500V | IF Voltage | 750V |

| IF frequency | 0.7-1KHZ | IF power | 1000KW |

| Rate temperature | 1250 degree | Energy consumption | 350-360KW.H/T |

Advantages of induction forge furnace:

1. The utility model has the advantages of obvious energy-saving effect and 20% saving compared with common equipment.

2. it is with high power factor and keeps over 0.98 with high order harmonic wave pollution.It is no need to add reactive power compensation device and harmonic wave control device.

3. It can achieve that one power supply cabinet for two furnaces.Transformer utilization rate is high.

4. The two furnaces can cast simultaneously and also can supply continuously molten steel casting.

5. Arbitrary power allocation, starting rate of 100%

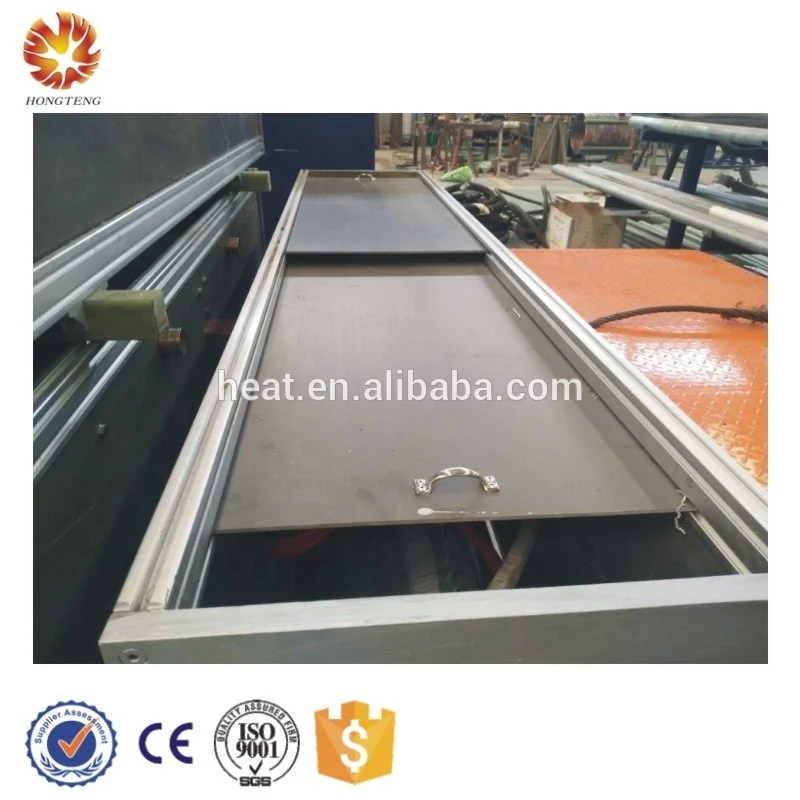

Induction forge furnace for forging steel bar

induction forge furnace for forging steel billet

We are professional manufacturer of medium frequency melting furnace, MF induction heating equipment.We are specializing in the production of various kinds of casting melting, forging, heating, steel production line.After more than twenty years hard-working,it has developed to high modern enterprise.

Our main products are as following: induction melting furnace, nonferrous metals copper aluminum production line equipment and ferrous metal whorl, angle, channel steel production line equipment ,etc. Our factory principle is"Quality is first,Client first" to offer high quality goods and serve clients fully is our working aim.

As one manufacturer, we have over 20 years of experience in manufacturing, designing, testing and R&D. Our factory covers an area of 100,000 square meters. Our products are sold all over the world and used in construction projects of various scales.We are dedicated in manufacturing top-class products with competitive price and our products are widely welcomed by domestic and foreign groups in the fields of construction, power, highway, railway, bridge erecting, and so on.

(Plywood) wooden case for packing electric induction forge furnace

one for packing induction heating power supply

one for packing induction forging furnace

shiped by sea

As a professional exporter,our target is to serve worldwide clients with high-quality products,great reliability,devoted responsibility,professional services and honorable credibility to meet customers' requirements in all aspects. We will supply you 24 hours a day and 7 days a week after-sale services.

1) We customize the products according to the customers’ requirements. If you are not sure about the exact product you want, we can give you some advices, according to your factory’s area, annual capacity, raw material, your finished products.

2) We provide the complete unit foundation flat layout chart so that the construction and installation can be done easily.

3) We provide the methods of the maintenance of products.

4) Engineers are available to service machinery overseas.

Q1: Our workers are not professional on the induction furnaces, how can we solve that?

A1:Don’t worry, when the induction furnaces arrive at the clients’ plant, our engineer will go and assist in installation, commission, and training until the workers can operate by themselves.

Q2:Which kind of power supply do you supply? Electricity or gas?

A2:Electricity.

Q3:What about your package? If damages happen, how do you solve?

A3:We take container loading, wire fixing. If damages occur, we will send the spare parts for you.

Q4:How can I trust your company and machine?

A4:Our factory have been in induction equipment ,induction furnace and product parts for around 15 years , entering alibaba for ads .And our machine have exported to East Asia, South Asia, the middle East Asia, Africa etc. areas and have a good feedback with no complaints.

Q5: Is it all right to make customer's own brand name?

A5: Sure, with your authorization of brand. We accept OEM service.

Q6: How do you control the quality?

A6: We have QC team comply with TQM to ensure the quality. Each step is in compliance to the standards. At the same time, we will take photos and shoot video for you if you need.

Q7: How long is your delivery time?

A7: Generally it is 7-14 days if the parts are in stock. or it is 25-30 days if the parts are not in stock, it is according to quantity.

please fill in the below blank about your requirement, and then click "send" to us . We will reply you within 12 hours.