Распродажа машина для гранулирования корма птицы курицы коровы свиньи

- Категория: Feed Processing Machines >>>

- Поставщик: Zhengzhou,Bainte,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-15-2025 | 94395.68 $* | 96283.47 $* |

| Jul-15-2025 | 76557.59 $* | 78088.62 $* |

| Jun-15-2025 | 92909.42 $* | 94767.89 $* |

| May-15-2025 | 92165.20 $* | 94008.92 $* |

| Apr-15-2025 | 73584.77 $* | 75056.51 $* |

| Mar-15-2025 | 90679.85 $* | 92493.3 $* |

| Feb-15-2025 | 89936.80 $* | 91735.27 $* |

| Jan-15-2025 | 89192.17 $* | 90976.18 $* |

Характеристики

- Lowest operating costs

- Easy to operate

- Strong, robust design

- Lowest maintenance costs

- Extra low energy consumption

- Compact and space-saving

- Most consistent quality of production

EFB pellet produciton lineEFB pellet produciton lineEFB pellet produciton lineEFB pellet produciton lineEFB pellet produciton line

Please feel free to send your inquiry at the below. This MKLH ring die pellet machine capacity ranges are from 500kg to 1500kg per hour. According to the characteristics of biomass fuel pelletizing, it is mainly designed for pressing combustible materials such as saw dust and grass into pellets. This pellet machine is usually equipped with 8mm and 10mm ring dies, because the 8mm and 10mm particle diameters are more favorable for combustion. Ring dies with other bore diameters can also be equipped according to different demands of users. Main Characteristics of Ring Die Wood Pellet Mill

1. Driven by gear, so that the output is improved by about 20% when compared with that of belt drive.

What Materials can be Pelletized by Ring Die Wood Pellet Machine?

|

Contact:Whatsapp:0086-18979060966 Wechat:18979060966

Introduction to Ring Die Aquatic Feed Pelletizer(animal feed pellet mill)

As the increasing price of conventional fish feed, modern aquatic feed pellets made by pellet mill are becoming more and more popular in aquaculture. This kind of aquatic feed pellet millis widely adopted by farmers who feed large quantity of aquatic animals. With advanced pelletizing technology and compact design, this feed pellet mill can ensure efficient pellets production with super quality. Pellets diameter can be from 2mm to 10mm to meet different aquatic species’ demand. Want to greatly save time and cost of aquatic farming? Try this specially designed aquatic feed pellet mill! While with this aquatic feed pelletizer, you should make sure that this pellet mill can only make sinking feed pellets, if you want to make floating fish feed pellets, you should choose puffing fish feed extruders(poultry feed making machine).

Superiorities of Ring Die Aquatic Feed Pellet Mill(animal feed pellet mill)

1. High quality finished pellets: The feed pelletizer adopts two or three layers jacketed conditioner, so the material can be fully cooked, meeting special needs and ensure high quality of final aquatic feed pellets.

2. High efficiency: Main driving adopts high precision gear transmission, the capacity can be improved about 20% compared to the belt transmission, and with low energy-consumption.

3. High pellets shaping rate: The international advanced spring coupling device is of novel and compact structure, ensures pellets shaping rate higher than 95%.

4. Safe and easy operation: Overload protection and electrical control system make the operation safe and easy.

5. Long service life: Multiple aperture ring die for choice, excellent craft of ring die ensure long service life of the key parts.

It can not only produce various kinds of high quality feed pellets for fish, eel, shrimp, crab, loach, bullfrog, etc, and can produce many kinds of pet feeds for cat, dog, rabbit and etc.

Common raw material can all be processed into aquatic feed pellets: rice dust, mustard cake, wheat chaff, maize, cotton seeds, fish powder, bone powder, innards and so on.

Contact:Whatsapp:0086-18979060966 Wechat:18979060966

Working Principle of Ring Die Feed Pellet Mill(animal feed pellet mill)

The feed ingredients run through feeder into conditioner and are mixed in the conditioner with hot steam, then they go into the pelletizing chamber through blanking taper slot. By scraper the powder material enters into the pelletizing zone. And then the material will be pressed by ring die and rollers into pellets. The pellets are discharged from the die hole and cut into the requested size by the cutter.

Technical Parameter of Aquatic Feed Pellet Mill(animal feed pellet mill)

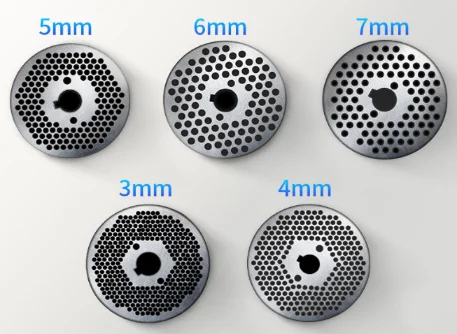

Pellets diameter: 2mm, 3mm, 4mm, 4.5mm, 5mm, 6mm, 8mm, 10mm

Pellets shaping rate: ≥95%

Pellets stability in water: ≥20Min

Roller working temperature: ≤85℃

Steam working pressure: 0.1-0.4Mpa

Steam temperature: 130-150℃

Model | BNT320 | BNT350 | BNT400 | BNT20 | SZLH508 |

Capacity | 2-5t/h | 1.5-8t/h | 2-10t/h | 3-12t/h | 4-20t/h |

Power | 37kw | 55kw | 90kw | 110kw | 132/160kw |

Dia. of mould | φ320mm | φ350mm | φ400mm | φ420mm | φ508mm |

Width of ring die | 90mm | 100mm | 120mm | 120mm | 156mm |

Speed of ring die | 305r/min | 336r/min | 307r/min | 287r/min | 287r/min |

Dimension | 2300*1000*2100mm | 3200*1100*1700mm | 3200*1300*1900mm | 3500*1500*2800mm | 3500*1500*2950mm |

Contact:Whatsapp:0086-18979060966 Wechat:18979060966

Introduction of Poultry Feed Pellet Mill(animal feed pellet mill)

Poultry feed is very important for breeding industry, but it is also troublesome to mix feed for the poultry every day. With the introduction of electric poultry feed pellet mill, now we can easily make powder feed into poultry feed pellets. Our electric poultry feed pelletizer is specially designed for small poultry farm or home use: driven by electricity, small body, light in weight and simple operation. Most important, the feed pellets produced by this electric poultry feed pelletizer have rich nutrition, good palatability and high digestibility.

Performance Features of Electric Flat Die Feed Pellet Mill

1. Driven by electric motor makes it more convenient and environmentally friendly.

2. No need to add extra water to the powder feedstock before pelletizing.

3. To make feed pellets with different diameters, you just need to replace a pellet mill die.

4. High temperature and pressure during the pelletizing can kill all kinds of parasitic ovum and other pathogenic microorganisms, reducing digestive system disease of poultry.

5. Low consumption, competitive price, long service life.

Application of Poultry Feed Pelletizer

Suitable for processing various kinds of solid grain into small feed pellets for poultry like chicken, duck, geese, quail and livestock including cattle, cow, rabbit, pig, etc.

The raw materials are easy to obtain, like corn, maize, wheat bran, rice, beans, etc.

Electric poultry feed pellet mill is popular with small feed pellet plant, breeding farm, and poultry farm.

Why Choose Poultry Feed Pelletizer for your CHICKEN?

This poultry feed pelletizer for small poultry farm or home use is different from other feed pellet mills. As for chicken, they are kept for fast and health growth. The feed of chicken should emphasize the nutrition content and ingredients. We developed this homemade chicken feed pelletizer and focused to increase the integrity of nutrition and palatability which can accelerate chicken to have more than usual. What’s more, chicken in different growing stages need different size feed pellets, with this machine, you can make feed pellets from 2-10 mm, meeting different needs.

Technical date of Electric Flat Die Poultry Feed Pelletizer

Model | Capacity(kg/h) | Power | Die meter | Weight | Dimension |

BNTPLM-120B | 60-100 | 3/2.2 kw | 120 mm | 60 kg | 750*350*650mm |

BNTPLM-150B | 90-120 | 4kw | 150 mm | 180 kg | 1000*430*950mm |

BNTPLM-200B | 200-300 | 7.5kw | 200 mm | 250 kg | 1000*430*950mm |

BNTPLM-200C | 200-300 | 7.5kw | 200 mm | 250 kg | 1000*460*900mm |

BNTPLM-230B | 300-400 | 11kw | 230 mm | 270 kg | 1140*470*970mm |

BNTPLM-230C | 300-400 | 11kw | 230 mm | 280 kg | 1140*540*930mm |

BNTPLM-260B | 400-600 | 15kw | 260 mm | 300 kg | 1120*520*1070mm |

BNTPLM-260C | 400-600 | 15kw | 260 mm | 310 kg | 1120*530*1070mm |

BNTPLM-300B | 600-800 | 22kw | 300 mm | 310 kg | 1270*520*1070mm |

BNTPLM-300C | 600-800 | 22kw | 300 mm | 310 kg | 1280*600*1050mm |

BNTPLM-360C | 700-900 | 22kw | 360 mm | 400 kg | 1340*580*1060mm |

BNTPLM-400C | 900-1100 | 30kw | 400 mm | 450 kg | 1520*600*1150cm |

Contact:Whatsapp:0086-18979060966 Wechat:18979060966

Dry type fish feed extruder introduction

If you have fish ponds or small aquatic farms, this dry type fish feed pelletizer is really cost-effective to make your own fish feed pellets compared with buying feed. With simple design and easy operation, it can help you make quality floating feed pellets for all kinds of fish, shrimp, crab etc. Besides, just change the different dies and you can get feed pellets with different sizes, wonderful taste and attractive color.

Fish Feed Pellet Machine Features

1. This dry type fish feed pelletizer can produce all floating, sinking, and slow sinking aqua-feed pellets just by adjusting feed formulation and degree of expansion.

2. Different molds can be chosen to make pellets with different diameters (0.9-15mm) and shapes.

3. Electric heating device is adopted to improve the feed expansion rate and pellets floating time.

4. Auto-temperature control system makes the temperature controlling more direct viewing and the parameter more precise.

5. High temperature and high pressure process can kill the salmonellosis and bacterial infections in materials and also makes the pellets easier to digest and absorb.

Raw materials can be processed by Fish Feed Extruder

Most fish feed pellet includes animal protein and plant protein: plant protein adopts corn flour, rice flour, wheat flour, soybean flour, peanut cake powder, and animal protein adopt fish meal, shrimp meal, crab meal, sleeve-fish meal and so on. You can add other ingredients according to the local fish live require.

Note: We can provide free formula after you make an order.

The Benefits of Puffed Fish Feed Pellets

1. From the fish feed extruder, feed pellets are in "popcorn" state, not only physical state has been changed, but also shape and internal structure of organic molecules has been changed, which make feed pellets easier to digest and absorb for fish.

2. After treatment of puffing, fragrance and palatability of the feed has been improved to stimulate appetite of animal.

3. High temperature and high pressure process can kill the salmonellosis and bacterial infections and makes the pellets Hygeian for fish.

4. The puffed fish feed pellets can float on the water surface without dissolution for over 12 hours, reduce feed waste and keep the water quality.

Dry type fish feed extruder working video

Parameters of Dry Type Fish Feed Extruder

Model | Capacity | Main power | Feeding power | Screw diameter | Cutting power |

BNT-DGP50 | 0.06-0.08t/h | 11kw | 0.4kw | φ50mm | 0.4kw |

BNT-DGP60 | 0.12-0.15t/h | 15kw | 0.4kw | φ60mm | 0.4kw |

BNT-DGP70 | 0.18-0.25t/h | 18.5kw | 0.4kw | φ70mm | 0.4kw |

BNT-DGP80 | 0.3-0.35t/h | 22kw | 0.4kw | φ80mm | 0.6kw |

BNT-DGP90 | 0.4-0.45t/h | 37kw | 0.4kw | φ90mm | 1.5kw |

BNT-DGP120 | 0.5-0.7t/h | 55kw | 0.4kw | φ120mm | 2.2kw |

BNT-DGP135 | 0.8-1.0t/h | 75kw | 0.4kw | φ133mm | 2.2kw |

BNT-DGP160 | 1.2-1.5t/h | 90kw | 0.75-1.1kw | φ155mm | 3.0kw |

BNT-DGP200 | 1.8-2.0t/h | 132kw | 1.5kw | φ195mm | 3.0-4.0kw |

Contact:Whatsapp:0086-18979060966 Wechat:18979060966

Diesel Livestock Feed Pellet Mill Introduction

Today livestock feed pellets are becoming more and more popular in the breeding industry for being rich in nutrition, good palatability and easy storage. Our flat die poultry feed pellet mill is your inevitable choice for making your own feed pellets. This small diesel feed pellet mill is very flexible, convenient to move and operate. What is more important, in the long run, the feed pelletizer price is more cost-effective than buying feed pellets , so it is especially favored by small farm holders and poultry breeders. For daily feed pellets production with small quantity, usually a feed pellet mill is enough, because you can grind the materials with any grinding machine that is available to you; after the pellets are discharged from a feed pelletizer, you can cool them in the sun and then store them in a container. While if the production is relatively larger and a little troublesome only depending on labor force, you can consider buying the axillary machines like feed hammer mill, etc to save time and labor.

Advantages of Diesel Engine Livestock Feed Pellet Mill

1. This flat die feed pelletizer is powered by diesel, free limit from electricity shortage.

2. Die-driven feed pellet mill can save much energy.

3. Easy to get materials: corn, wheat, soybean, grass, alfalfa, straw, rice hull and so on.

4. Can make feed pellets for poultry and livestock, like chicken, duck, rabbit, pig, etc.

5. By changing pellet mill dies, you can realize making feed pellets with different diameters with one feed pellet mill.

Portable Poultry Feed Pelletizer Enjoys High Popularity

In recent years, the improvement of portable feed pelletizer facilitates human life greatly. It is available for farmers to own a homemade poultry feed mill for making feed pellets anywhere at any time. It helps farmers turn all kinds of grains into feed pellets. For individuals, this diesel poultry feed pelletizer can not only save you a lot of budget on the basis of providing sufficient feed, but also accelerate the growth of poultry effectively and provide the abundant nutrition the poultry need. So numerous farmers begin to choose a portable poultry feed pelletizer to process own feed pellets.

Technical Parameter of Small Poultry Feed Pelletizer with Diesel Engine

Model | Capacity | Power | Mold diameter | Weight | Packing size |

BNTPLM-120A | 70-100kg/h | 8HP | 120 mm | 100 kg | 870*440*730mm |

BNTPLM-150A | 100-150kg/h | 8HP | 150 mm | 150 kg | 870*440*730mm |

BNTPLM-200A | 250-350kg/h | 15HP | 200 mm | 250 kg | 1180*560*950mm |

BNTPLM-230A | 300-400kg/h | 22HP | 230 mm | 380 kg | 1180*560*950mm |

BNTPLM-260A | 400-600kg/h | 30HP | 260 mm | 500 kg | 1840*700*1160mm |

BNTPLM-300A | 600-800kg/h | 55HP | 300 mm | 650 kg | 2270*620*1260mm |

BNTPLM-360A | 700-900kg/h | 55HP | 360 mm | 750 kg | 2270*620*1260mm |

BNTPLM-400A | 900-1000kg/h | 55HP | 400 mm | 850 kg | 2270*620*1260mm |

Feed pellet machine (aka: pellet feed machine, feed pelletizer)

The pellet feed molding machine is a feed granulation equipment. It is a feed processing machine that directly compresses particles by crushing materials such as corn, soybean meal, straw, grass, rice husk, and peanut meal.

How to reduce the cost of feed and meet the nutritional needs of various livestock and poultry has become the primary problem that the majority of farmers and feed industries need to solve urgently. Straw biochemical protein feed technology is to pass the crop straw through pulverization, granulation and other technical measures, so that lignin is softened, crude protein, crude fiber, crude fat and the like are degraded into substances that are easily digested and absorbed by poultry, and a large amount of fermentation is also produced. The bacterial protein becomes soft and ripe after fermentation, and the granulation increases the palatability of the livestock. The average level of crude protein and amino acid is increased by 40.6% and 95.8%, and the levels of arginine, cystine and histidine are increased. It has also been greatly improved, sugar and fat content increased, and vitamins and growth factors such as B, D, and E are produced, and then mixed with other raw materials to prepare full-price feed. The pellet feed machine presses into nutrient-rich feed pellets to feed the livestock. The amount is increasing and the growth is accelerated. Reducing food input (the nutritional value of 270 kg of grain feed per ton of straw feed) saves on feed costs and increases farmers' income.

Feed pellet machine common faults and troubleshooting methods:

First, because the pellet machine produced by our company is a precision bearing transmission, the high-efficiency power input is ensured while the power loss in the belt conveyor of the pellet machine is eliminated. The precision bearing gearbox pellet motor is directly connected to the pellet machine to make the pellet machine It has more power during operation and lower power loss. There are many precision bearing parts in the granule machine gearbox that need lubrication. After receiving the granule machine, add 4L gear oil to the granule machine. Different oil types may have different amounts.

The butter on the main shaft of the pellet machine has been filled before leaving the factory, and it needs to be greased every 15 days. (Need to choose high temperature butter)

Second, the pellet machine just received will not reach the normal output, which is a normal phenomenon, because the pellet machine is all new machine, the pellet machine just running does not reach the running state, after the standby device is used for a period of time, the pellet Please understand that the production and discharge quality of the pellet machine will reach the state after the parts of the machine are grounded to the state.

1. The output of the feed pellet machine is too low or even granules or a lot of powder. Although this problem does not occur often, if it appears, it means that you have not grinded the pressure roller and the grinding disc during the grinding process of the pellet machine. The reason for the similar problem may be the poor finish of the grinding disc for the first time. After grinding the disc with the abrasive or after using for a period of time, the output of the pellet machine will reach the normal output.

2. If the moisture content of the feed is not well mastered, it will affect the discharge of the pellet machine. The moisture in the raw material should be controlled at 13%-20%, because the pellet machine has the function of drying and curing, and the moisture in the raw material is in the pellet machine pressing process. The pellets that are dried in the pellet machine can be bagged after being dried for 5-10 minutes under normal temperature conditions.

3. The gap between the pressure roller and the grinding disc of the pellet machine is too large, which may be one of the reasons that the pellet machine does not discharge. Adjust the gap between the pressure roller and the grinding disc, screw the pressure roller with one hand, adjust the corresponding bolt, adjust When the pressure rollers on both sides are swaying, slightly tight, it means that the pressure roller and the grinding disc have been adjusted.

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com