Промышленный бумажный ролик для груди складной сушки используемый при

- Категория: Paper Machinery Parts >>>

- Поставщик: Qinyang,Nianhai,Papermaking,Mesh,Industrial,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.80 $* | 0.32 $* |

| Aug-16-2025 | 0.67 $* | 0.80 $* |

| Jul-16-2025 | 0.56 $* | 0.88 $* |

| Jun-16-2025 | 0.93 $* | 0.63 $* |

| May-16-2025 | 0.84 $* | 0.5 $* |

| Apr-16-2025 | 0.75 $* | 0.31 $* |

| Mar-16-2025 | 0.9 $* | 0.14 $* |

| Feb-16-2025 | 0.43 $* | 0.32 $* |

| Jan-16-2025 | 0.75 $* | 0.32 $* |

Характеристики

Roller for Dryer Clinder

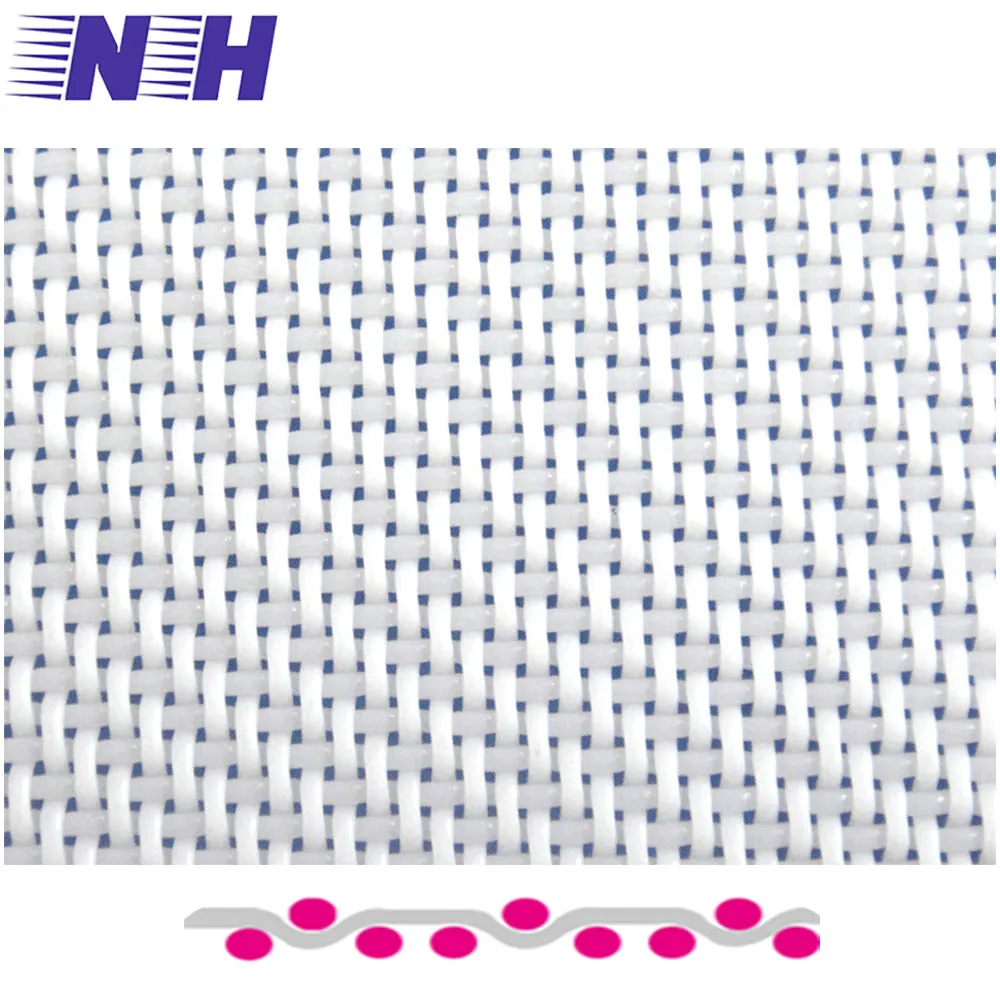

The press roll is the main component of the press device. There are many types of press rolls, flat roll, vacuum roll, grooved press roll, blind hole roll and controllable medium and high roll. After absorbing the advantages of vacuum pressure roller, groove roller and blind hole roller, several other new types of pressure rollers have appeared. The purpose of developing new press roller is to improve the dehydration efficiency and improve the quality of the paper sheet. Reducing the negative impact of pressing on the paper industry.

Industrial paper breast roller folding roll industrial paper roll paper folding roller breast roll

Types :

1, natural rubber / nitrile rubber roller

2, neoprene roller

3, silicone roller

4, polyurethane rubber roller

5, EPDM rubber roller

6, nylon roller, iron roller and stainless steel roller

7, can also be customized according to customer requirements

Industrial paper breast roller folding roll industrial paper roll paper folding roller breast roll

Feature:

1, a wide range of hardness: 20-100 degrees | ||||||

2, high temperature resistance, up to 300 degrees | ||||||

3, oil resistance, wear resistance, solvent resistance, acid and alkali resistance, aging resistance | ||||||

4, strong production capacity, a variety of mature formulations, but also for the customer design and build. | ||||||

5, a large range of processing, ultra-long roller manufacturing experts.(diameter 10MM-670MM, length: 50MM-8200MM) | ||||||

graphite rubber. Air bellows and sealing strips are made by Leripa or Aisa Paper Tech.

disperse stress and mechanical shock resistance effectively during operating; Excellent dehydration ,low nip pressure which

prevents dandy marks and crushing of paper sheet ;High wear resistance ,chemical resistance . The rubber roller has moderate

hardness and elasticity, high oil resistance, washing solvent resistance, wear resistance and shape stability. Soft rolls are generally made of SBR, CR and PU. The surface of the hard stick was originally made of copper and later replaced with polyester resin.

Packing Details : wooken packing

Delivery Details : 3-30 days after deposit.

Our main products are a full set of new and second hand paper making equipment with a maximum net with of 6000mm and a working speed of 700m/min.It mainly includes a packaging paper production line with an annual output of 200,000-200,000 tons, a cultural paper production line with an annual output of 1-10 million tons, a tissue paper production line with an annual output of 20,000 tons and various special paper production lines.

Look forward to hearing from you sooner and establishing a long friendly business relationship with you . We promise we will do our best to help you .Besides ,welcome you to visit our factory at anytime.

NH Paper Machinery Industrial Group Co., Ltd.

Mob/WhatsApp/Wechat:

0086-157 2152 2521

Web:

http://www.qynhgroup.com/