DIP припоя машина автоматическая двойная для пайки волной переменного тока 50-250 мм PCB производственная линия плата со светодиодным

- Категория: Другое сварочное оборудование >>>

- Поставщик: Shenzhen Wanbo Hi-Tech Co., Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-18-2025 | 457346.89 $* | 466493.19 $* |

| Jul-18-2025 | 370918.48 $* | 378336.20 $* |

| Jun-18-2025 | 450144.5 $* | 459147.77 $* |

| May-18-2025 | 446543.72 $* | 455474.73 $* |

| Apr-18-2025 | 356514.74 $* | 363644.27 $* |

| Mar-18-2025 | 439340.3 $* | 448127.33 $* |

| Feb-18-2025 | 435739.12 $* | 444454.98 $* |

| Jan-18-2025 | 432138.38 $* | 440781.7 $* |

Характеристики

Electronics DIP 0-250mm PCB width Automatic Double Wave Soldering Machine

wave soldering machine

Product Features:

1. Styling streamlined shell design, beautiful appearance, easy to clean.

2. Solder furnace is made of alloy material. High strength and high hardness aluminum alloy guideway with long service life.

3. Use Siemens PLC computer control technology to ensure the reliability and stability of the system.

4. The rodless cylinder spray device can automatically adjust with the width of PCB, and effectively save flux.

5. The wave peak of tin furnace is controlled by stepless electronic frequency conversion, and the height of wave peak can be controlled independently.

6. Special flux isolation device, flux smoke from the special exhaust air and recovery channels to meet environmental requirements.

7. Programmable automatic switch machine date, time, temperature control parameters.

8. Equipped with cooling module (optional air cooler, temperature compensation module, suitable for lead-free and various process requirements.

9. Imported micro chemical pump, propanol cleaning agent, automatic circulation cleaning chain claw.

10. Two-stage independent preheating, ceramic heating pipe device, fully activated flux activity. Direct heat radiation to the bottom of the PCB plate, fast heating, long service life.

11. Patented die-casting titanium alloy chain claw, non-stick tin, never deformation, long life, transport PCB stable and reliable.

12. The whole process transparent observation window, convenient observation production and maintenance operation.

13. Tin furnace manual lifting and entry and exit, easy to adjust. Adopt backrest design to prevent maloperation of damaged machine.

14. The transportation system adopts stepless electronic speed regulation pid closed-loop control, and the transportation speed is stable.

15. The over plate automatically starts wave to minimize the amount of tin oxidation.

16. The temperature control system adopts PID closed loop control mode, and the temperature control is stable and reliable.

17. The stored parameters can be quickly called, and the operating variables are set in the PCB with good process consistency.

18. With short circuit and overcurrent protection system.

Product parameters:

|

PCB Working width |

Max. 250mm |

|

760±10mm |

|

|

PCB conveyor direction |

Left to right / right to left (optional) |

|

PCB conveyor speed |

0-2.0m/min |

|

Preheating zone length |

1500mm |

|

2 stages |

|

|

Preheating temperature |

0~250℃ |

|

Solder volume |

150-200KG |

|

Solder temperature |

0~350℃ |

|

Temperature control type |

PLC Key button+PID |

|

Flux storage tank |

Max:5.2L |

|

Power |

3 phase 5 wire 380V |

|

Power for heating up |

12KW |

|

Power for operation |

4KW |

|

Air supply |

4-6kg/cm2 12.5L/min |

|

Weight |

650KG |

|

Dimensions L*W*H |

2700*1200*1650mm |

|

Model |

Wave soldering machine WS-200DS |

|

Substrate width |

Max200mm |

|

PCB board transport height |

760±10mm |

|

PCB board transport speed |

0-1.8M/Min |

|

Preheating zone length |

700mm |

|

Number of preheating zones |

2 |

|

Preheating zone power |

4kw |

|

Preheating zone temperature |

Room temperature - 200 ° C |

|

heating method |

Full hot air |

|

Number of cooling zones |

1 |

|

cooling method |

Natural wind cooling |

|

Tin furnace power |

6kw |

|

Tin furnace tin content |

120-150KG |

|

Tin furnace temperature |

Room temperature - 300 ° C |

|

Transportation direction |

about |

|

Temperature control method |

Temperature control table control |

|

Machine control mode |

Instrument control + touch screen |

|

Flux capacity |

Max4.2L |

|

Spray method |

Japan SA-6 nozzle |

|

power supply |

3-phase 5-wire system 380V/220 |

|

Starting power |

10kw |

|

Normal operating power |

3kw |

|

Gas source |

4-7KG/CM2 12.5L/Min |

|

Rack size |

L1450×W1100×H1600MM |

|

Dimensions |

L2250×W1100×H1600MM |

|

weight |

Approx 550kg |

|

Preheating unit |

|

|

Extended preheating zone |

Total length 700mm, two-stage full hot air temperature independent control |

|

Temperature control mode |

Temperature meter |

|

Heating unit |

Hot air control, imported Taiwan heating core |

|

Preheating power |

Total power 4kw |

|

Tin furnace parts |

|

|

Tin furnace material |

Lead-free material 3MM thick |

|

Tin furnace tin volume |

120-150kg |

|

Tin furnace temperature range |

Room temperature - 300 ° C |

|

Height adjustment range |

0—50mm |

|

Tin furnace power |

6kw |

|

Tin furnace move mode |

Manual |

|

Wave spray head |

Guaranteed plane tin wave |

|

Economical operation |

Through the PLC and photoelectric switch control, the plate sprays the wave function to reduce unnecessary waste. |

|

Wave motor |

Taiwan Taichuang company high temperature motor, peak height digital adjustment |

|

Heating unit |

Special long life, special solid state relay, tin liquid heating are ± 2 ° C |

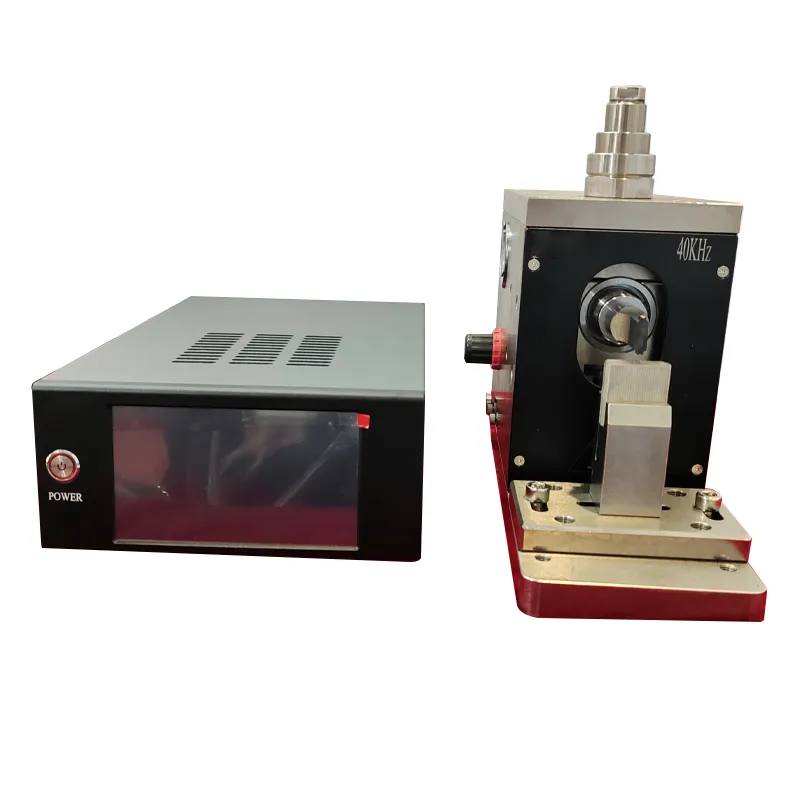

Shenzhen Wanbo Hi-tech Co Ltd is specializing in manufacturing TAB bonding machine, ACF bonding machine, LCD screen laser repair machine, soldering station, soldering tips, digital multimeter, adjustable dc power supply, programming electronic load, LCR meter, oscilloscope, lamp mafnifier, smt machine, pick and place machine, reflow oven, solder paste, miscroscope, ultrasonic cleaner, ultrasonic welding machine, assembly line, LED chip packaging machines etc. We have R&D team based in Shenzhen. Our goal is to build perfect world.

Похожие товары

Недорогая паяльная машина для инфракрасного нагревателя IC T962A

Стальной стержень арматурный сварочный аппарат

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com