Полуавтоматическая ручная круглая маркировочная машина для жестяных

- Категория: Pharmaceutical Packaging Machines >>>

- Поставщик: Minhua,Pharmaceutical,Machinery,Co.,Limited

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.51 $* | 0.53 $* |

| Aug-17-2025 | 0.88 $* | 0.77 $* |

| Jul-17-2025 | 0.54 $* | 0.39 $* |

| Jun-17-2025 | 0.9 $* | 0.84 $* |

| May-17-2025 | 0.32 $* | 0.89 $* |

| Apr-17-2025 | 0.23 $* | 0.63 $* |

| Mar-17-2025 | 0.74 $* | 0.55 $* |

| Feb-17-2025 | 0.97 $* | 0.32 $* |

| Jan-17-2025 | 0.61 $* | 0.15 $* |

Характеристики

Product Description

Round Bottle Labeling Machine

Parameters of Self-adhesive Labels: (only for references):

The whole working process for producing roll labels on a labelling machine include label conveyance, positioning, generation and pasting as well as rewinding of backing paper. For smooth labelling, the requirements for labels are generally as follows:

Label Spacing: 3-4mm±0.2mm

The spacing between upper and lower edges of labels and backing paper: 2mm

Surface Materials: basis weight: 78g/m2 (±10%); thickness: 0.064mm (±10%)

Backing Paper: Basis weight: 61g/m2 (±10%); thickness: 0.055mm (±10%)

With consistent release force and even thickness, backing paper is more or less tensile. Translucent GLASSINE backing paper is generally 60 to 80g heavy with appropriate fibre density, tightness and evenness. It won’t be easily broken at the time of labelling and its overall transmittance must be consistent. The sensors can correctly recognize positions of labels.

Tensile Strength: Machine Direction: 16kg/25mm

Horizontal: 7kg/25mm

Tear Resistance: Machine Direction: 25g/piece

Horizontal: 31g/piece

Effectiveness for Machining: Before labelling, the static electricity inside roll labels must be removed so that stiff labels can be produced and separated from backing paper, because static electricity makes it impossible to produce labels or makes labelling not standard. During die cutting, avoid cutting the backing paper, or else labels can’t be produced or the backing paper would be torn.

3. Related Items of Quotation

Term of Validity | : | The quotation shall be valid within 1 month from the date of quotation. |

Terms of Payment | : | Make 50% of total payments for goods as deposit at the time of placing an order. The remained payments shall be paid after the supplier’s equipment is produced and accepted, while the goods shall be shipped. |

Term of Delivery | : | In general, standard machines are available in warehouses, and those ordered can be received within 20 business days after ordering. |

Way of Transportation | : | Transported by land; the freight shall be assumed by the seller. |

Warranty Period | : | Within a year upon shipment, the products which malfunction shall be repaired free of charge by the Seller as long as they are used normally. |

Installation Training | : | The seller shall dispatch personnel to freely install equipment and train operators for one time in the buyer’s factory. |

Technical Indicators | : | The technical indicators in the seller’s product catalog or additionally agreed between the buyer and the seller shall prevail. |

Samples for Testing | : | The buyer shall provide enough samples for testing (including but not limited to labels and samples for labelling) within 7 days. |

4. About mimumi

Dongguan mimumi Smart Equipment Co., Ltd mainly provides various labelling machines and solutions for food projects. It mostly sells its labelling machines through “places”, and food via “terminals”. So far, it has owned more than 3,000 customers satisfied by its services. Will you be its next customer to be satisfied by its services? As a leader in the market of labelling machines and an innovator of food projects, Dongguan mimumi Smart Equipment Co., Ltd has delivered over 30,000 standard labelling machines and monthly ships 200 to 300 machines to accommodate market needs dependent upon the mimumi Community, over 20 patented labelling technologies and more than 500 place partners. It has offered overall solutions to food projects for more than 100 food companies, including product tracing.

I. Dongguan mimumi Smart Equipment Co., Ltd mainly provides following products and services.

1. High-quality labelling products

1.1. Self-adhesive labelling machines, fully-automatic/semi-automatic flat labelling machines, round bottle labelling machines and fully-automatic double-side labelling machines.

1.2. Glue labelling machines, semi-automatic glue labelling machines and fully automatic glue labelling machines.

1.3. Hot glue labelling machines, semi-automatic hot glue labelling machines, straight line/rotary hot glue labelling machines.

1.4. Sleeve labelling machines, 250/350/450 sleeve labelling machines, shrink sleeve labelling machines

1.5. Special labelling machines, real-time printing/labelling machines, electric wire labelling machines, wine labelling machines and mobile phone lamination machines and so on

2. Technologically Mature Solutions for Food Projects

2.1. Solutions for Tracing Food Safety

2.2. Canned Food Projects

2.3. Packaged Food Projects

Dongguan mimumi Smart Equipment Co., Ltd relies on its strong technology research and development projects. Its labelling machines, with better performances than similar products within the industry, can meet most requirements of the labelling industry. Its solutions for food projects contribute to overall innovations and upgrades of food projects so that production, warehousing and e-commerce sales of food enterprises form an organic whole.

The machines are widely used in industries of food, beverage, medicine, automobile parts, electronics, daily chemicals, electric wires and cables. No matter for standard labelling machines or overall solutions for product tracing and anti-counterfeiting in food projects, we always provide you with the most economical and effective high-quality solutions from your standpoints.

5. After-sales Service Guarantees and Advantages

n During normal working hours, we can make instant responses to our customers within 2 hours by communicating with them and promptly rushing to the sites near the places where the customers are. During non-working hours, we also assure that we could respond to our customers’ requests within 4 hours.

n With a special customer service hotline at the HQ of Dongguan, we can actively and rapidly respond to all customers’ incoming calls, consultations, complaints and queries about shipments and so on.

n We manufacture machines in China and corresponding parts or accessories, providing services. Hence, we can supply all major parts and accessories in time without needs for customs declaration or uncertainties in date of shipment, which are problems for machines and accessories imported from foreign countries.

n After machines are commissioned to be normal, our engineers will train 1 to 3 operators for 1 to 3 days at the customer office. When necessary, we can prolong our training to ensure operators can independently perform operations, commissioning and daily maintenance.

n We have built a professional team for central after-sales services to regularly call our customers to know about the use of machines and make prompt reports about customer requirements or problems of machines to related personnel.

n We make special plans for each machine, sort out and archive all after-sales services and corresponding records, which are regularly reviewed by special personnel to give prompt feedbacks about potential problems.

n The warranty period of machines is one year. In case of any damages or faults resulting from non-human factors, we will repair or replace the products free of charge for our customers. We provide lifelong after-sales services for our products.

Technical parameter :

List of Key Components | ||

1.1 | J7810 Stepping Mechanism for Labelling | 1 set |

1.2 | Adjustment Mechanism | 1 set |

1.3 | Bottle Unscrambling Mechanism | 1 set |

1.4 | Conveying Mechanism | 1 set |

1.5 | Label Affixing Mechanism | 1 set |

1.6 | Human-machine Interface | 1 set |

1.7 | Al Alloy Power Distribution Box | 1 set |

1.8 | Manuals and Common Tools | 1 set |

Remarks: The prices listed above exclude taxes, but include freight and after-sales services.

2. Equipment Configurations and Technical Parameters

SN | Names | Brands | Quantity | Remarks |

1 | Stepper Motor | YAKO/JMC | 1 set | Shenzhen |

2 | Stepper Driver | YAKO/JMC | 1 set | Shenzhen |

3 | Conveyor Motor | Wanshsin/OPG | 1 set | Taiwan |

4 | Speed Governor for Conveyor Motor | Wanshsin/OPG | 1 set | Taiwan |

5 | Label Sensor | Leuze/DataSensor | 1 set | Germany/Italy |

6 | Electric Eye for Substance Detection | Panasonic/Riko | 1 set | Japan/Taiwan |

7 | Programmable Logic Controller (PLC) | Panasonic/Vigor | 1 set | Japan/Taiwan |

8 | Al Alloy Frame | mimumi | 1 | Dongguan Remarks: Configurations may be reasonably adjusted at the same levels according to actual delivery term of materials, or revised as per customer requirements. |

Technical Parameters of Equipment

Voltage Specifications: AC220V, 50HZ

Reference Dimensions: About 2000 (L) * 1300 (W) * 1400 (H) (mm)

Height between Conveyor Belt and Ground: 850-950mm (dependent upon customer requirements)

Weight: About 185kg

Labelling Speed: About 30-180 labels/min (related to products and label size)

Labelling Precision: ±1mm (excluding product and label errors)

Applicable scope: diameter (φ25mm-φ100mm), height (≤diameter*3)

Applicable Labels: (backing paper) W (15mm~100mm),L (20mm~320mm)

Biggest Labels: diameter: 280mm; internal diameter of roll: 76mm

Air Pressure for Working: 0

Operating conditions: 10-40℃ (mainly impacts label viscosity)

Relative Humidity: 15-85%

Different machine

Remark: Machine will be designed according to customer's detail requirements. Please contact with us for choose.

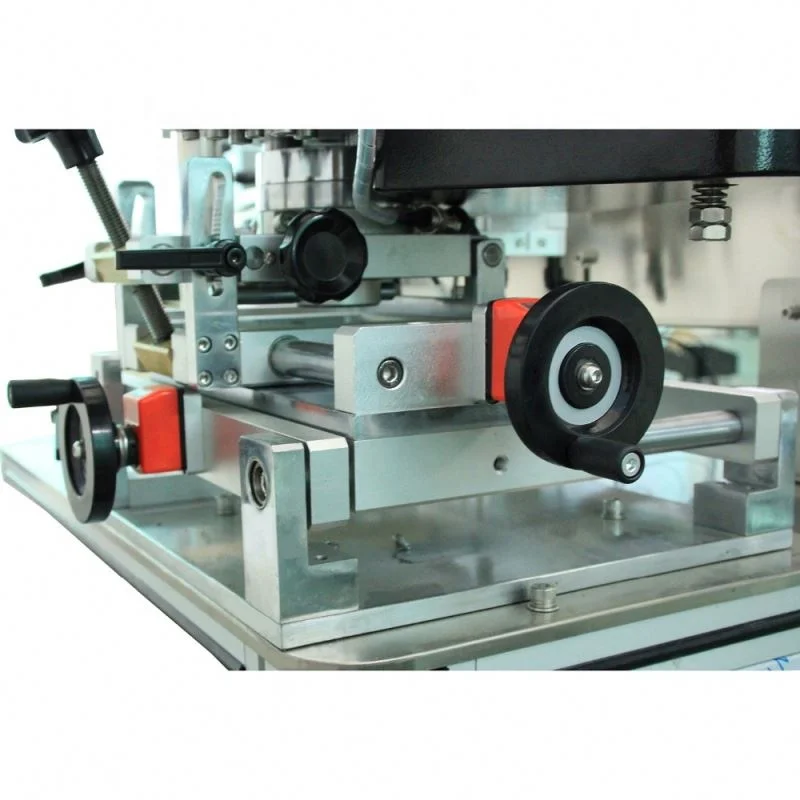

Product Pictures

Details

Product Samples

Packaging & Shipping

Our Company:

Shanghai Zixiong Pharmaceutical Machinery Co., ltd is a professional manufacturer and supplier of pharmaceutical and chemical machinery and equipment in China. We are located in Shanghai.

We have a disciplined factory and fairly professional technical engineers. We will provide personalized customized service for you. We have designed and developed many types of machinery and equipments, including tablet press, soft and hard blister packing machine, capsule filling machine,

clean-room project, soft-gel production line, glass-lined reactor, centrifuge, granulator, mixer, dryers, pulverizer, cartoner and rollers, etc.

Our products are of good quality and reputation. All customers have been quite satisfied with our products. We have established long-term business relations with many customers. Our products are exported to many countries & areas, such as the USA, Australia, Canada, the UK, Spain, Hungary,Russia,Germany, Sweden, Korea, India, Indonesia, Pakistan, Thailand, Vietnam, , Japan, Denmark, Romania, Bulgaria, , South Africa, Nigeria, Argentina and Chile. Besides machinery and equipment, we also supply production lines and turn key projects.

In ZIXIONG you can get your desired goods with the best prices and good quality. Welcome your enquiries from all over the world.

Our Services

Pre-sales service:

1.We provide presales service in various forms, making investment budge, manufacturing, planning, so that customers can make a reasonable plan with less cost.

2.We will fist check customer’s goods and goods size, then we will recommend suitable wrapping machine to 100% suitable.

3.We will recommend and offer machine according to customer’s use and purchase budget.

In-sale service:

1.We will supply each manufacturing step photo for customer checking on time.

2.We will prepare packing and shipment according to customer’s needing in advance.

3.Testing the machine and making video for customer’s checking.

After-sale service:

1.We will guarantee the machine quality for 1 year.

2.We provide free training and answer customer's question on technology in time.

Our Customer

Welcome to Shanghai. Welcome to visit our company.

Certificate

FAQ

1. What about your baling machine quality?

Our factory has more than 10 years experience in mechanical processing; all our machines already get ISO9001, SGS certificate, CE certificate; already exported into many countries and areas; already got customer’s good reputation.

2. What about your baling machine price?

Anytime we will make quality as factory life, no matter price is good or not for us. Quality is first, on the top quality basis, Sure you will get reasonable and satisfied price!

3. How can you ensure the machine’s quality after we put the order?

Before the delivery, we will send you machine’s pictures and videos, or you can come to us to have the quality checking by yourself, or by the third party inspection organization contacted by your side.

4.What about your installation service and sales service for baling machine?

1>Guarantee is one year, we will supply spare parts or send engineers to your side if you need, we will give you service anytime, 24 hours, 7days.

2>We already prepare technical manual and operation video to show our customers, then it will be easy to install and use the machine.

3>It is free to train your worker in our factory or in your side or by video.

Contact Us

Sales Manager : Jack Meng

WhatsApp and Mobile:0086-13621903276

Skype:ccsser