Поставка с фабрики подвижный сварочный аппарат для пвх полотно

- Категория: >>>

- Поставщик: Shanghai,Puxiong,Industrial,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.42 $* | 0.38 $* |

| Aug-17-2025 | 0.62 $* | 0.48 $* |

| Jul-17-2025 | 0.8 $* | 0.40 $* |

| Jun-17-2025 | 0.53 $* | 0.86 $* |

| May-17-2025 | 0.35 $* | 0.83 $* |

| Apr-17-2025 | 0.97 $* | 0.11 $* |

| Mar-17-2025 | 0.12 $* | 0.20 $* |

| Feb-17-2025 | 0.79 $* | 0.50 $* |

| Jan-17-2025 | 0.93 $* | 0.1 $* |

Характеристики

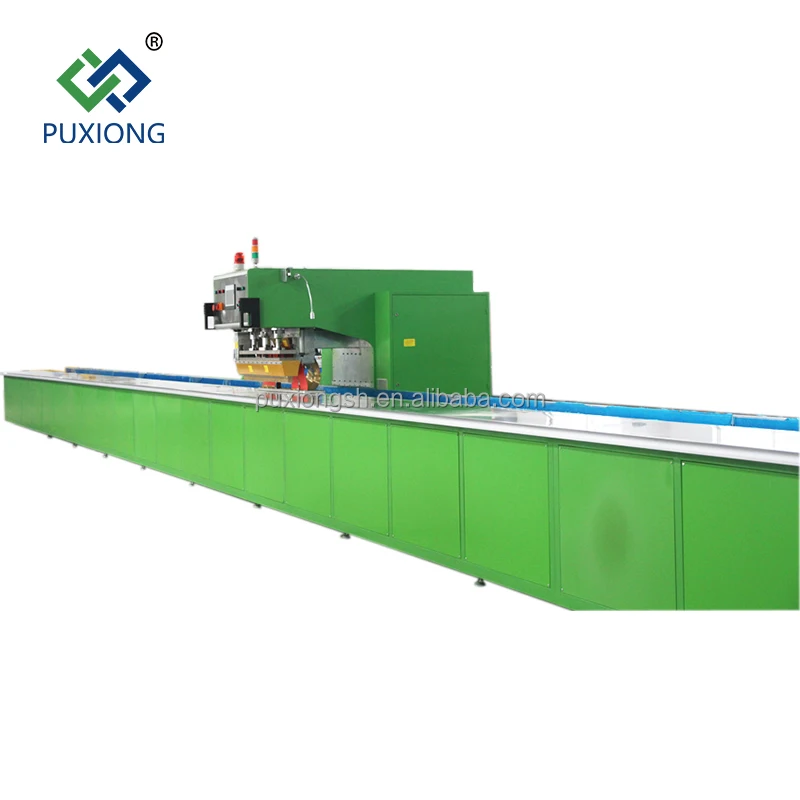

Factory supply movable welder for PVC canvas tarpaulin

Mainly used for welding awning,tent,car shed,stretch membrane film,space membrane,

construction membrane structure,water bladder,pools,water bed,inflatable toys,hot air

balloon,solf digester,bridges water bags,military water bag,PVC shutter doors,car

tarpaulins,canvas,movie curtain,outdoor fabric film,outdoor awning,advertising printing

cloth,etc.The welding effect is perfect,high strength,and the material surface is smooth &

beautiful.

1.Track Welder is Mainly Used for Large Area Materials’ Linear Welding.For example:air

film gymnasium,coal shed,large tent, military tent,inflatable tent, etc.

2. Continuous Working, High Welding Efficiency:The power of this equipment is 25KW/35KW

usually,the bar can reach 1.2m/time so as to continuous automatic working.

3. The Track Length is Customized According to Customer's Requirements:At present,we

had manufactured several 120 meters’ track,which is the world's longest and largest

high frequency track welder.The same track can be installed two heads which can be

used at the same time.The track length is 3m/section generally,it can be customized.

4. Precise Welding:The equipment is driven by the servo motor,the speed is adjustable,

braking has no jitter,to ensure the straight line’s welding without any offset.

5. The Worktable is Long and Smooth and Seamless,the Storage Space is Large and Beautiful;

6. Equipped with Intelligent PLC Control System:User name login right’s protection,

parameters memorize automatically and the data can be used repeatedly,thermostat

controller system,quick change mould,simple and quick operation,ensure that new

staff adapts quickly to improve production efficiency and ensure the quality.

7. Multiple Protection, Safe Working Environment:Equipped with a high-sensitive spark

protection system and overcurrent protection device, to protect the mold and materials

to the maximum extent,under the situation of parking or overflow; Setting up multiple

barrier protection,strict control high frequency magnetic field,working environment is

more secure.

Model | PXMS-A07P |

Power | 25KW |

Voltage | 380V/Customized |

Pressure Mode | Pneumatic |

Air Pressure | 0.6MPa Adjustable |

Oscillating Frequency | 27.12MHz±0.5% |

Throat Depth | 825mm |

Welding Bar | L1200mm*W60mm(Customized) |

Length of Track | 15m-140m / Customized |

Control Method | Intelligent / Mechanical |

Weight | Depends |

Note: The length of track can be customized according to customers’ requirement. | |

1.How to install & run the machine?

The seller offers instruction video,and English version manual will be shipped together

with the machine.If necessary,the seller will offer overseas support.

2.What is warranty of the machine?

Warranty is one year,and maintenance is lifelong.The worn-out parts will be sent

according to the buyer's condition.While guarantee is not valid if the machine is used in

wrong way or it is not maintained as shownin the technical handbook.

3.How to get spare parts?

The seller will enclose some quick wear parts with the machine when buyer places an

order.

4.How to guarantee the machine received in a good condition?

QC department of the seller will control the quality from raw material to the finished

product.When the machine is finished,the seller will send the buyer inspection video or

photos.Or buyer can come to seller’s factory to check it .