Сушильная машина Soy

- Категория: Vacuum Drying Equipment >>>

- Поставщик: Changzhou,Doing,Machine,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.91 $* | 0.34 $* |

| Aug-19-2025 | 0.51 $* | 0.62 $* |

| Jul-19-2025 | 0.11 $* | 0.72 $* |

| Jun-19-2025 | 0.81 $* | 0.34 $* |

| May-19-2025 | 0.37 $* | 0.77 $* |

| Apr-19-2025 | 0.77 $* | 0.53 $* |

| Mar-19-2025 | 0.26 $* | 0.29 $* |

| Feb-19-2025 | 0.57 $* | 0.74 $* |

| Jan-19-2025 | 0.96 $* | 0.21 $* |

Характеристики

Main features

1. Used for drying or reacting of pastes, filter cakes, powders, and granules under vacuum condition;

2. Heating area: 10-300 M2

3. Volume of drying chamber: 500-25000 L

4. Working type: Batch type or continuous

5. Heat source: steam, hot water or hot oil

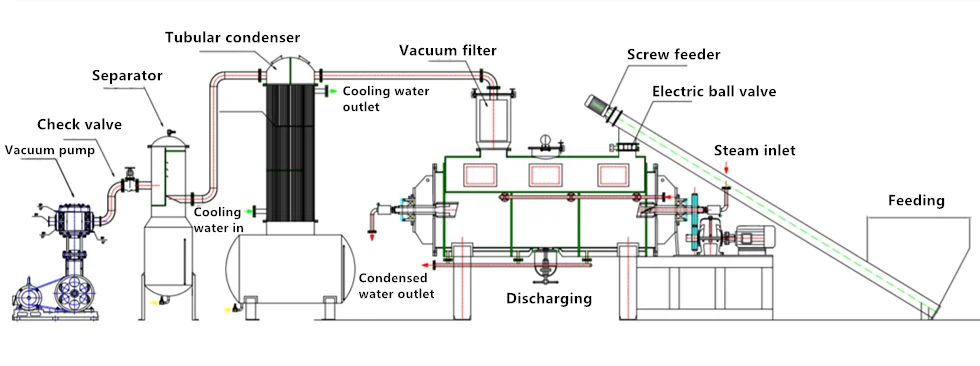

Working Principle

Technical advantages

1) High thermal efficiency which can reach 95%

2) Heat transfer medium does not contact the product.

3) Gas is not used to convey the product. Off-gas flow is minimal.

4) Precise control of temperature

5) Uniform product quality, through mixing and movement of the product

6) High heat transfer area to process volume ratio - reduced floor space

7) Easy to operate, requires minimal attention

8) Safer than direct drying when processing combustible material

9) Simple durable design for easy and low maintenance

Main technical parameters

Model | PZG-600 | PZG-1000 | PZG-2000 | PZG-4000 | PZG-6000 | PZG-8000 |

Volume L | 600 | 1000 | 2000 | 4000 | 6000 | 8000 |

Working volume L | 420 | 700 | 1400 | 2800 | 4200 | 5600 |

Heat transfer area M2 | 6 | 10 | 20 | 40 | 60 | 80 |

Evaporation rate kg/M2/hr | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 |

Working temp. oC | 60-280 | 60-280 | 60-280 | 60-280 | 60-280 | 60-280 |

Vacuum degree Pa | 300-1500 | 300-1500 | 300-1500 | 300-1500 | 300-1500 | 300-1500 |

PZG-6500 vacuum paddle dryer in Hungary

PZG-3000 vacuum paddle dryer in India

PZG-2000 vacuum paddle dryer in China

PZG-8000 vacuum paddle dryer in China

PZG-3000 vacuum paddle dryer in China

PZG-6000 vacuum paddle dryer in Canada