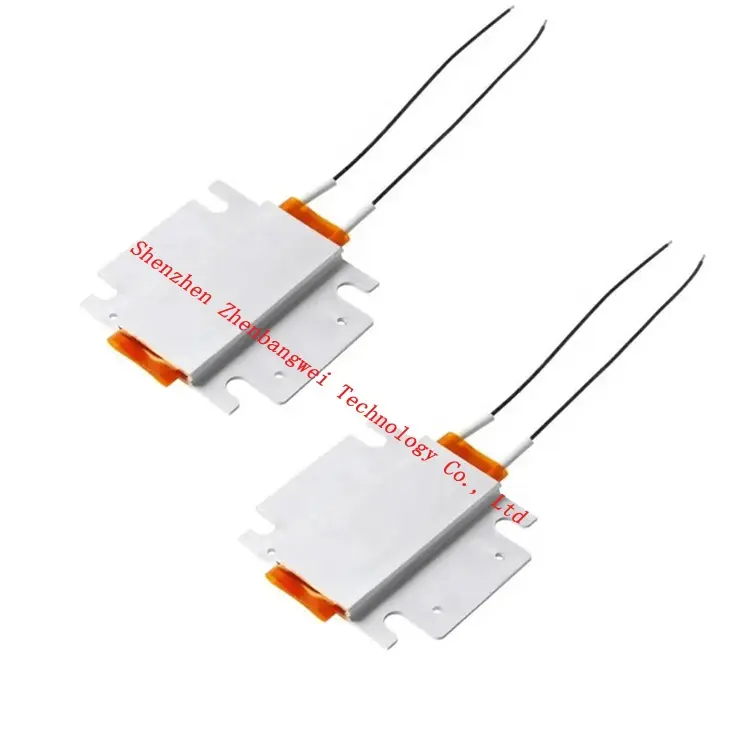

Нагревательные элементы из нержавеющей стали типа I U W трубчатый нагреватель

- Категория: Heating Equipment >>>

- Поставщик: Shenzhen,Vsec,Electronic,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.71 $* | 0.44 $* |

| Aug-16-2025 | 0.83 $* | 0.28 $* |

| Jul-16-2025 | 0.93 $* | 0.96 $* |

| Jun-16-2025 | 0.21 $* | 0.34 $* |

| May-16-2025 | 0.10 $* | 0.23 $* |

| Apr-16-2025 | 0.99 $* | 0.33 $* |

| Mar-16-2025 | 0.1 $* | 0.7 $* |

| Feb-16-2025 | 0.96 $* | 0.7 $* |

| Jan-16-2025 | 0.51 $* | 0.17 $* |

Характеристики

Guangdong shenzhen electric finned heating element conditioner parts air tubular heater

he use of high-quality stainless steel materials, modified oxidized protactinium powder, high resistance electric heating wire, stainless steel sink, formed by production equipment and advanced production technology, and has carried on the strict quality management, fin electric heating tube heating occasions can be installed in the blowing pipe or other static, air flow. The fin type electric heating tube is winding metal heat sinks on the surface of common components. Compared with the ordinary components, the heat dissipation area is expanded by 2~3 times, that is, the surface power load of the finned elements is 3~4 times of that of the ordinary components. Because the length of components is shortened, the heat loss of itself decreases. Under the same power conditions, it has the advantages of fast heating, uniform heating, good heat dissipation, high thermal efficiency, long service life, small size and low cost. According to the requirements of the user, a reasonable design, easy to install. Products are widely used in machinery manufacturing, automobile, textile, food, household appliances and other industries, especially in air conditioning air curtain industry.

1. Voltage can be designed as: 12-660V

2. Single injection power: 50W-20KW

3. Materials are: 10 # iron, T4 copper, 1Cr18Ni9Ti stainless steel, Ti titanium and so on.

4. Specifications are: U-shaped, W-shaped, shaped, with cooling fins electric heating pipe, explosion-proof electric heating pipe

Material requirements:

1.Reasonable choice of raw materials of electric tube, is to ensure the quality of electric heating power of the premise.

2. Pipe selection principle: temperature, corrosion resistance.

3. Resistance wire selection: Cr20Ni80

4. Magnesium oxide powder selection: industrial grade magnesium oxide powder

5. Seal material selection: silicone oil +704 sealant

Application of electric heating pipe

1. Small size, high power: the electric heater mainly used within the cluster tubular heating element, each cluster-type tubular electric heating element maximum power of 5000KW.

2. Fast thermal response, high temperature control accuracy, comprehensive thermal efficiency.

3. Wide range of applications, strong adaptability: The circulating heater can be applied to explosion-proof or general occasions, its explosion-proof grade up to B-class and C-class, its pressure up to 10Mpa. And according to the user needs the cylinder with vertical or horizontal installation.

4. High heating temperature: the heater design maximum operating temperature up to 850 ℃, which is the general heat exchanger can not get.

5. Fully automatic control: Through the heater circuit design, can easily achieve the export temperature, pressure, flow and other parameters of automatic control, and computer networking, to achieve man-machine dialogue.

6. Long life, high reliability: The heater is made of special electric materials, coupled with the design of the power load are more reasonable, the heater with multiple protection, making the heater safety and life greatly increased.

7. Stainless steel electric tube is a metal tube for the shell, along the tube in the center of the central axis of the spiral electric heating alloy wire (nickel chromium, iron chromium alloy) the gap filled with a good insulation thermal conductivity of magnesia sand, Sealed with silicone or ceramic, this metal armored electric heating element can be heated air, metal molds and a variety of liquids. ] In the high-temperature stainless steel seamless tube evenly distributed high-temperature resistance wire, in the gap part of the dense filling thermal conductivity and insulation properties are good crystalline magnesia powder, this structure is not only advanced, high thermal efficiency, and heat evenly, when the high temperature Resistance wire in the current through, the heat generated by the crystallization of magnesium oxide powder to the metal pipe surface diffusion, and then transferred to the heated parts or air to achieve the purpose of heating.

Q:Are you a trade company or a manufacturer?

A: We are manufacturer.

Q:What is your payment terms?

A: 30% TT deposit in advance and 70% balance before shipment.

Q:Sample time and delivery time ?

A:Normally it will take u about 7 days to finish the sample,and for mass production is based on quantity.

More inquiry,please feel free to contact with me anytime!